Metal

Seurat: Speed Is How AM Competes Against Machining, Casting, Forging

“We don’t ask for DFAM first,” says CEO. A new Boston-area additive manufacturing factory will deliver high-volume metal part production at unit costs beating conventional processes.

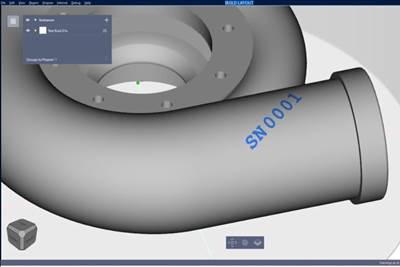

Read MoreVelo3D’s Flow 5.0 Software Enhances Control Over 3D Printing Process

The software’s new features include user-selectable core parameters, preprint analysis to identify potential costly and time-consuming errors, and rapid resequencing for multipart prints.

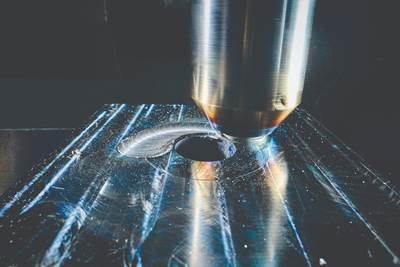

Read MoreMazak MegaStir Will Be Exclusive Tooling Supplier for Meld Solid Deposition Technology

Mazak MegaStir will provide its hard metal expertise along with tooling specifically developed for the Meld process that also incorporates the use of friction as part of its solid deposition process.

Read MoreSLM Solutions, Assembrix Work to Ensure Secure Remote Printing

Following the integration of Assembrix VMS software into SLM Solutions’ machines, both companies are now working to ensure the enhanced safety and full protection of customers' intellectual property, which is made possible through the utilization of blockchain and encryption technologies.

Read MoreIMPACT Project Call Worth $11.7M in Funding for Casting, Forging

The project call is for demonstrating productivity and yield benefits for casting and forging manufacturing via additive manufacturing technologies, execute techno-economic analysis for metal powder AM, and to bridge component sourcing gaps with AM parts for casting and forging applications.

Read MoreWhat Is the Role of Sintering in Binder Jetting? (Video)

And how strong are green parts prior to sintering? Filmed at HP, here is a look at sintering, including the shrinkage from green to sintered binder jet parts.

WatchAmnovis Simplifies Regulatory Submission for 3D Printed Titanium Implants

Amnovis has incorporated its additive manufacturing process expertise and experience with titanium 3D printing into an FDA Master File to help facilitate customers’ regulatory submissions for 3D printed titanium implants.

Read MoreUltiMaker’s Method XL 3D Printer for Engineering Applications

The printer features a temperature-controlled heated build chamber and heated build plate, enabling users to print large production parts with manufacturing-grade ABS.

Read MoreXact Metal Celebrates 100th 3D Metal Printer Order

The company says this milestone comes after the successful launch of its XM200G in 2021, which is Xact Metal’s second metal 3D printer and which has significantly expanded the company's reach and customer base.

Read MoreIperionX to Provide 100% Recycled Titanium Metal Powders to SLM Customers

It is said IperionX’s titanium technologies enable the production of high-quality titanium powders from 100% recycled titanium feedstocks to significantly reduce the carbon footprint and environmental impact of titanium.

Read More