Metal

The Benefits of Vertically Integrating Metal 3D Printing and Machining

Having 3D printing and machining within one organization enables Addman’s engineers to collaborate and consolidate so it can quickly make successful metal 3D printed parts.

Read MoreVolkmann’s PowTReX Rolls to 3D Printers for Easy Installation, Movement

The metal powder transfer and recovery system now features a mobility package as standard, making it easier for companies to automate the powder transfer, extraction and sieving processes at multiple printers without investing in multiple machines.

Read MoreSintavia Developing Additive Manufacturing Facility for US Navy

Sintavia is collaborating with Bechtel Plant Machinery to develop a dedicated additive manufacturing facility in support of the United States Naval Nuclear Propulsion Program.

Read MoreSenvol Commercializes Siemens Energy’s Material Databases

Databases for Ti64, Inconel 625 and Inconel 718 were generated by Siemens Energy on its laser powder bed fusion machines. Although the data was initially intended exclusively for internal use, the company recently decided to make the data commercially available.

Read More3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

WatchNXCMED Provides Custom Implants, Complex Surgical Devices

The company focuses on solving the toughest surgical challenges by delivering patient-specific implants that enable an overall quicker surgery, faster recovery time, and significantly reduced risk of infection to the surgical area.

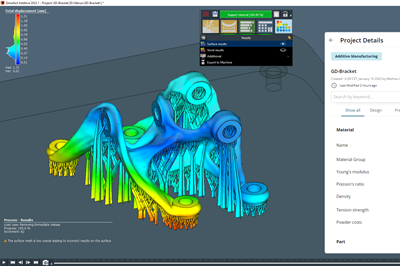

Read MoreNexus, Hexagon's Digital Reality Platform Offers Collaboration Solutions Congruent With AM Needs

Nexus, Hexagon’s open, digital reality platform, enables collaboration among manufacturers and promotes the freedom to innovate using an array of digitalized tools.

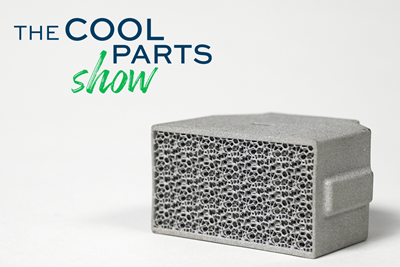

Read More3D Printed Metal Filters Protect Circuit Breakers from Explosion: The Cool Parts Show #57

New high-voltage circuit breakers from Schneider Electric make use of 3D printed metal filters to protect people and equipment in the event of an overload. Binder jetting provided both the geometric complexity and price point needed for these parts.

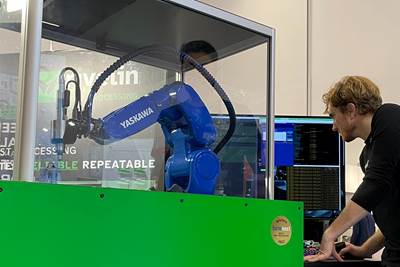

WatchThe Robot Craftsman: Force Sensing and Vision Help Realize Automated AM Postprocessing (Includes Video)

Automated production via additive manufacturing will need automated postprocessing. This UK startup is equipping robots with the capabilities needed for critical, fine-detail finishing of metal 3D printed parts.

WatchAmerica Makes’ Project Call for LPBF Cross-Platform Consistency

Project entry requirements include registration at TRX Industry Day at UTEP by Wednesday, March 8, 2023; with the submission deadline set for Friday, April 7, 2023, by 5 p.m. ET.

Read More