Dyndrite Collaborates With AMFG for Cross-Platform 3D Metal Automated Production

AMFG powered by Dyndrite is an integrated solution that is said to unlock the full potential of metal 3D printing by bringing order-to-part automation, eliminating bottlenecks and streamlining the entire production process for increased efficiency and cost savings.

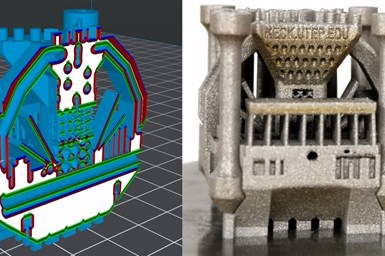

Dyndrite's software is said to give LPBF materials, part/process and applications engineers power and control over their geometry, build specific toolpathing and laser parameters. Photo Credit: Dyndrite

Dyndrite is partnering with AMFG to offer AMFG powered by Dyndrite, a software solution that brings an integrated solution to both streamline and automate metal AM production. The solution combines Dyndrite’s GPU-accelerated computation engine used to create digital manufacturing hardware and software with AMFG’s MES and workflow software for managing manufacturing workflows.

This integrated solution is said to unlock the full potential of metal 3D printing by bringing order-to-part automation, eliminating bottlenecks and streamlining the entire production process for increased efficiency and cost savings.

Additive CAM, also known as 3D print preparation, often remains a manual, time-consuming and tedious roadblock to a truly autonomous manufacturing workflow. This is especially true where machines from multiple vendors are involved or where different customer orders must be collated into the same build.

AMFG powered by Dyndrite combines advanced order processing capabilities with the industrial 3D printer processing capabilities of Dyndrite. The combined solution enables laser powder bed fusion (LPBF) users and service bureaus to deploy automated ordering, collating and dynamically processed part production services. In addition, customers can drive cross-platform LPBF printing from one application and experience hundreds of hours of labor reduction per year.

The companies say an investigation among AMFG customers reveals impressive benefits from the program. This includes saving more than 500 hours in labor per machine per year for powder-based processes alone. Additional advantages include minimized human error, expedited turnaround times and enhanced machine utilization. Monthly, this translates to 220-300 hours saved for six machines, which equates to approximately 40 hours per printer per month. The integration of AMFG with Dyndrite not only streamlines the manufacturing process but can also significantly impact businesses by facilitating quicker time to market and fostering trust through the reduction of time to ship.

“Our partnership with AMFG allows us to stay at the forefront of the Additive Industry. We are excited to further streamline the production process through automated print preparation, allowing us to deliver high-quality parts to our customers faster than ever before,” says Richard Minifie, Ricoh senior additive manufacturing engineer. “This has not only helped us improve our customer satisfaction but also deepened our relationship with Dyndrite, as we work together to explore new opportunities enabled by a true automated additive CAM solution.”

It is said the ability to deploy automated LPBF additive CAM solutions revolutionizes its applicability as a reliable AM production process. The combination of AMFG and Dyndrite transforms the technology from a promising but cumbersome concept to a practical and reliable manufacturing tool.

Preparing build files for additive manufacturing processes, including LPBF, can be a complex and time-consuming process, often taking days or weeks to complete. This problem is compounded when working with multiple machines from different vendors as each machine often has its own proprietary method for driving the process. The lack of standardization of file formats, parameters and protocols also means engineers and technicians must spend more time adjusting and tweaking build files. With the challenges of the skills shortage across manufacturing, it has become more difficult to train and retain technicians with technical proficiency across multiple machine and software standards. This is all without considering the cost of paying numerous legacy software licenses and modules to manually prepare build files. These issues are especially acute for service bureaus that work across multiple platforms and require streamlined part production and managed labor costs.

AMFG powered by Dyndrite, provides an autonomous manufacturing workflow. The benefits of each software complement each other to form a unified solution include AMFG’s order management system which receives and collates orders from multiple customers, sorted by machining process and parameters. Next, the disparate parts enter AMFG software powered by Dyndrite, whose GPU-accelerated CAM engine enables those parts to be nested, supported, labeled and toolpaths generated for compatible machines, including Aconity3D, EOS, Renishaw, SLM Solutions and others.

Next, production build data reenters AMFG’s MES, which harnesses its production planning capabilities to provide real-time build status updates and analytics, as well as its QMS to ensure jobs are completed with no compromise in quality. The AMFG MES powered by Dyndrite eliminates countless engineering hours spent manually prepping and collating build files and acquiring costly software modules for each metal platform acquired.

The solution also enables automated process-to-part capability from one application for cross-platform LPBF printing via bidirectional data exchange between MES and ToolPath generation app.

"We are entering a new era of manufacturing. One driven by data and automation,” says Keyvan Karimi, AMFG founder and CEO. “By adopting Dyndrite, we enable data automation down to the toolpath, unlocking the full potential of each machine, while growing efficiency and reducing the potential for human errors. Dyndrite’s cutting-edge technology is enabling our LPBF customers to produce complex parts with unprecedented precision, speed and reliability, giving our industry the boost it needs to compete with traditional manufacturing techniques."

The partnership between AMFG and Dyndrite is said to mark a significant step toward a seamless production process for 3D metal machines. “By combining the strengths of our respective software, we’ve created a one-stop-shop solution that streamlines the complex and time-consuming task of driving the AM process,” says Harshil Goel, Dyndrite founder and CEO. “With AMFG using our engine, manufacturers can expect increased efficiency, consistency and reliability, making LPBF a more practical and adoptable tool in their production process.”

- Read about Dyndrite’s collaboration with Novanta to enhance laser-based AM metal printing machine capabilities.

- Learn more about Dyndrite’s end-user software which expands development for LPBF machines. The system supports multioptic build strategy operations and laser parameter control limited only by vendor openness.

- Check out this article about Dyndrite’s partnership with SLM Solutions to maximize digital manufacturing software tools. The companies are working together to enable users to fully create SLM parameters and tool paths to fit their individual needs, maximizing materials development and application or part-specific build rate strategies.

Related Content

Savage Automation Delivers 3D Printed Commercial Manufacturing Aids

The company's approach to designing end-of-arm tooling and other devices has evolved over the years to support longevity and repairs.

Read MoreChuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Read MoreUltiMaker Targets Light Industrial Applications With 3D Printer Designed for the Factory Floor

The company’s Factor 4 3D printer introduced this week is designed to complement conventional manufacturing equipment including CNC machining and automation.

Read MoreDMG MORI: Build Plate “Pucks” Cut Postprocessing Time by 80%

For spinal implants and other small 3D printed parts made through laser powder bed fusion, separate clampable units resting within the build plate provide for easy transfer to a CNC lathe.

Read MoreRead Next

Bike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More