Metal

FFF 3D Printing for Metal: Sintering Can Wait

Separating 3D printing from high-temperature processing is part of how the Markforged Metal X realizes a price less than established metal AM equipment.

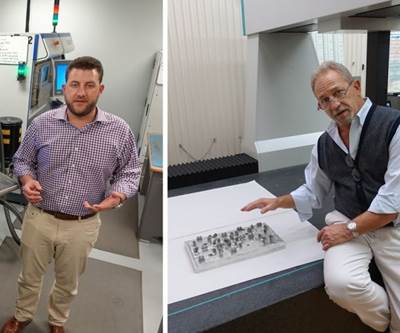

Read MoreAt Rapid: A 73-Year-Old Machine Shop’s Journey into Metal AM

Imperial Machine & Tool Co. presents at Rapid 2017 about incorporating metal additive manufacturing into a traditional machine shop environment.

Read MoreGE Team Secretly Printed a Helicopter Engine, Replacing 900 Parts with 16

GE Additive’s Ehteshami says, “To make these parts the ordinary way, you typically need 10 to 15 suppliers, you have tolerances, you have nuts, bolts, welds and braces.” With additive, “all of that went away.” The helicopter project is a detail in a story worth knowing.

Read MoreLaser Optimization Helps Brings AM to the Next Level

A new productivity-boosting technology, called parallel mode, redefines metal 3D printer process speed.

Read MoreDesign Enhancements for Conformal-Cooled Insert Leverage 3D Printing Capabilities

A collaborative mold project reveals that the value of 3D printing isn’t in the process, it’s in the products.

Read MoreStaying Focused on the Promise of AM

For this company, realizing that promise is a long-term undertaking. In the short term, it involves sometimes saying no.

Read MoreDoes Additive Manufacturing Make Sense in a “Subtractive” Machine Shop?

Definitely yes, says this shop—a metal 3D printed part is almost always a machined part as well, and an established machine shop is perhaps the best business to realize AM’s promise for production.

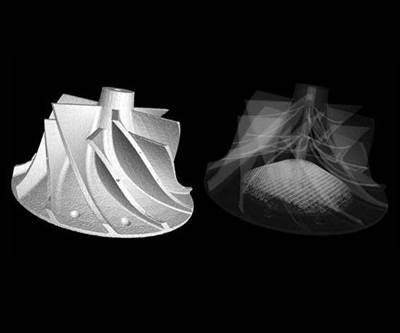

Read MoreVerifying Structural Integrity of Metal 3D-Printed Parts

X-ray computed tomography, or micro CT, offers insight into the inside of AM parts.

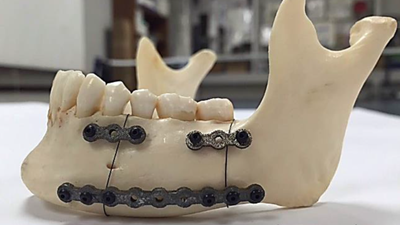

Read MoreAdditive Manufactured Fixation Plates Match Stiffness and Shape of Patient’s Jaw Bone

Research shows that NiTi fixation plates manufactured with controlled porosity using SLM can be matched to the stiffness of a patient’s lower jaw bone as well as its shape.

Read MoreDissolvable Support Structures for Metal? Researchers Validate This Possibility

A 3D-printed stainless steel part was built using a support structure made of a different metal. No mechanical removal of the support structure was needed. The support was entirely dissolved away, eliminating an often-difficult manual step.

Read More