Dissolvable Support Structures for Metal? Researchers Validate This Possibility

A 3D-printed stainless steel part was built using a support structure made of a different metal. No mechanical removal of the support structure was needed. The support was entirely dissolved away, eliminating an often-difficult manual step.

Support structures are a reality of 3D printing. If the part’s features can’t resist gravity while they are being grown and while they are still incomplete, then material must to be added to the design and to the build to support the form’s bridges and overhangs while the part is taking shape. These support structures then have to be removed to finish the part.

Certain polymer 3D printing processes have solved this problem. Supports can be printed in a material different from the main part that is dissolvable in a postprocessing solution. The support structures melt away within this solution, leaving only the intended part behind. In metal, by contrast, support removal is more difficult—and more crude. Supports are frequently removed from metal AM parts using pliers or chisel. The rough manual work is inefficient and risks damaging the part itself.

Could something like the same approach used in plastics—dissolving supports away—apply to metal 3D printing as well?

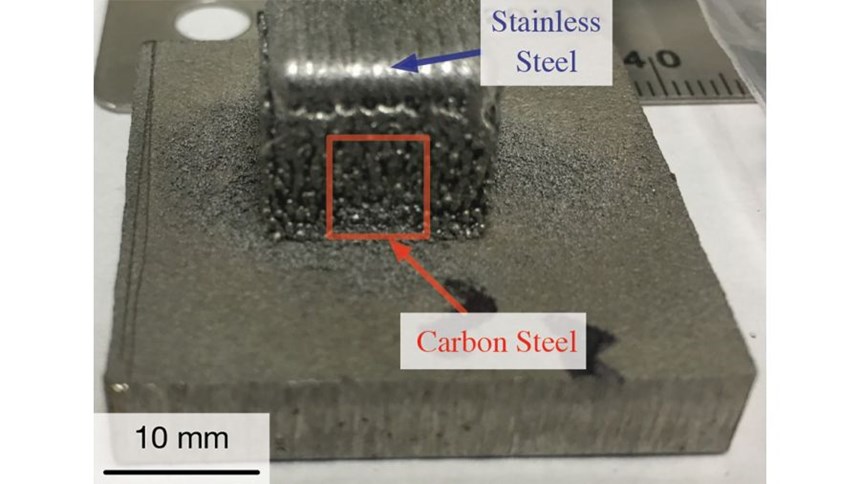

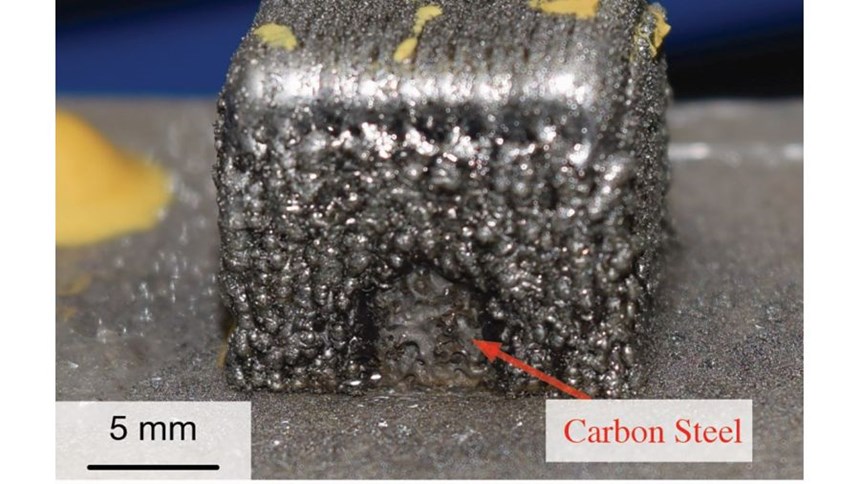

Answer: Yes. That is the finding of an evaluation performed recently on a part 3D printed in stainless steel. The researchers involved in the study were Owen Hildreth of Arizona State University, Kevin Chasse of the Naval Surface Warfare Center, and Abdalla Nassar and Timothy Simpson, both of Pennsylvania State University’s Center for Innovative Materials Processing through Direct Digital Deposition (CIMP-3D). In the experiment these researchers conducted, the stainless part’s bridging overhang was held up by a support volume made of carbon steel, with this support then washed away through electrochemical etching in a solution of nitric acid.

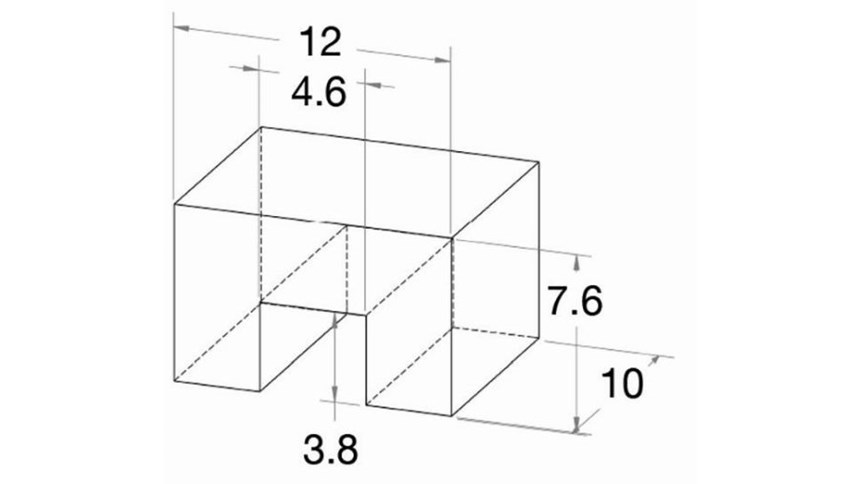

The drawing in the series of illustrations above shows the dimensions of the test piece. 3D printing was performed on an Optomec Laser Engineered Net Shaping (LENS) machine using two powder feeders to apply the two different steels in the same cycle. A volume of carbon steel filled the entire 3.8 × 4.6 × 10-mm volume underneath the stainless steel component’s bridge.

Compared to stainless, carbon steel has greater potential to oxidize. Differences in oxidation tendency have been leveraged to obtain sacrificial material in other applications. On boats, for example, sacrificial zinc oxidizes to protect the stainless steel hull.

One notable finding of the 3D printing experiment is that oxygen is an aid to efficiency. Etching with the acid solution for 10 hours caused only a 1.4-mm depth of support material to be dissolved from each side of the part. This was slow going. But when O2 bubbling was added, another 6 hours was enough to dissolve all the rest of the support metal away. Ultimately, the removal was so complete that no additional manual or mechanical work was necessary to aid support removal.

An important question addressed with this test was whether the electrochemical etching would have an adverse effect on the final part. In this case, it did not. Indeed, the part was left in the acid solution 10 minutes after all of the support metal was gone, with no observable damage to the intended component. The clear implication of this finding is that chemical dissolving potentially provides an efficient, unattended method for batch removal of support structures as additive manufacturing is applied in full-scale production.

Update: More recent work has validated an option for dissolving support structures when the structures and the part are all one material (the case with powder bed fusion). This approach involves engineering thin supports and infusing carbon into the material to facilitate controlled dissolution. Read the follow-up article.

Related Content

Possibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreAM 101: What Is Binder Jetting? (Includes Video)

Binder jetting requires no support structures, is accurate and repeatable, and is said to eliminate dimensional distortion problems common in some high-heat 3D technologies. Here is a look at how binder jetting works and its benefits for additive manufacturing.

Read MoreDMG MORI: Build Plate “Pucks” Cut Postprocessing Time by 80%

For spinal implants and other small 3D printed parts made through laser powder bed fusion, separate clampable units resting within the build plate provide for easy transfer to a CNC lathe.

Read MoreRead Next

3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read More