Laser Optimization Helps Brings AM to the Next Level

A new productivity-boosting technology, called parallel mode, redefines metal 3D printer process speed.

Share

Read Next

Metal 3D printer manufacturer Sodick first launched its OPM250L 3D metal printer at the 2016 International Manufacturing Technology Show (IMTS) where Phoenix DeVentures of Morgan Hill, California, showcased its success with the new hybrid machine.

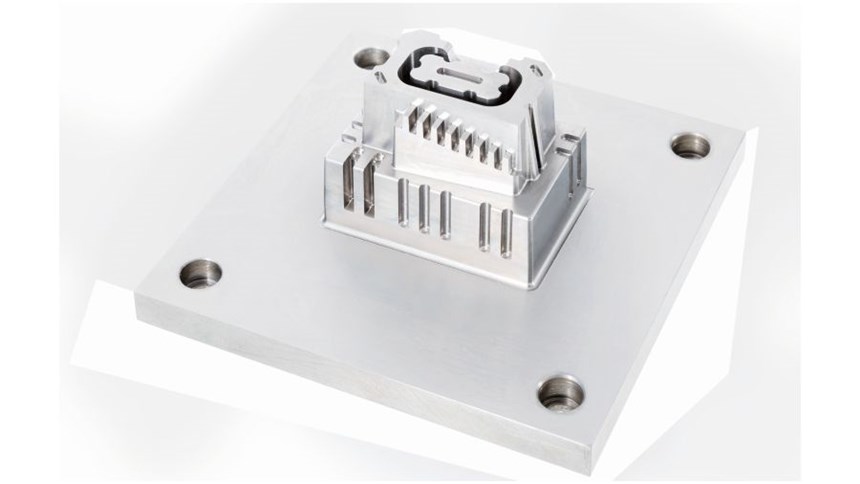

The OPM250L is a 3D printer that combines laser sintering of metals with a high-speed machining center to produce precision machined components with features that are not possible with machining processes or 3D printing alone. “It brings everything together by integrating the laser sintered layers with machining,” says Phoenix DeVentures CEO Jeff Christian.

Laser Sintering Plus Machining

Using 3D printers to build prototypes for testing was always very important to Christian. Since he first acquired a Stratasys FDM machine in 1997, he has kept his eye out for the opportunity to do more with 3D printing. Specifically, printing injection molds and shooting parts in engineering resins, rather than simply printing prototypes. The new hybrid OPM250L machine does more than that. Christian shared how it nearly eliminates EDM, reduces part warpage and dramatically reduces cycle times via conformal cooling.

Typically, it would be necessary to make 15-20 electrodes for a mold, sometimes more. Plus, any feature that has to be a square corner or an internal corner on the mold (external corner on the part) has to be EDMed. With the OPM250L, the EDM steps can be avoided.

The laser sinters metal layer upon layer to build a specified number of layers. The default is set to 10 sintered layers, but can be changed as needed. Then the milling machine cuts the finish surfaces 10 layers thick (0.020" at a time). “So, if you have a very tall part with very deep slots in it, you are not coming back in and EDMing these, you are machining these from the base up as it builds. You nearly eliminate EDM,” says Christian.

One of Christian’s initial concerns was warpage. He says that grown parts tend to warp or pull upward, similar to welding. Melting then cooling all the steel causes it to shrink, resulting in warpage. However, Phoenix developed techniques along with Sodick that nearly eliminate the warpage, according to Christian.

He also notes the value of conformal cooling using 3D printing. “I can run cooling close to the mold surface through a serpentine pathway and drop cooling time and overall cycle time of molding parts. Our best case was a reduction in total cycle time by 50 percent. Typical reduction is closer to 30 percent,” says Christian. That means buying fewer molding presses because it’s possible to get more throughput on his machines through molds with conformal cooling. According to Christian, his molding supervisor prefers molds with conformal cooling because they set up faster and easier, and part consistency is easier to achieve.

Phoenix Deventures bought the OPM250L primarily as a moldmaking machine for the manufacture of its medical products, such as implants, catheters and dental devices. “Being able to print steel molds faster on this machine has allowed us to get more output through those prototype molds. Case in point: We printed a mold insert on a different laser sintering machine that then needed to be polished by hand, taking 3 to 4 days to get the required surface. As a test, we then decided to build the same mold on the OPM250L. After 14 hours overnight, we had steel mold inserts finished perfect to size,” says Christian.

Parallel Mode

Since then AM has continued to ease the engineering process. It is the great facilitator, according to Christian. And, Sodick technology plays a valuable role in this continued AM development with its new parallel mode, a high-performance 3D printing technology for the OPM machines.

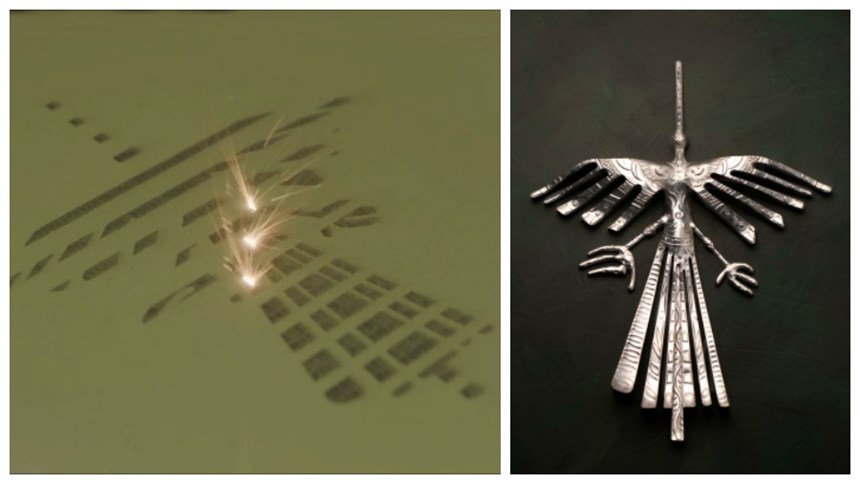

This unique technology does not add more laser units to the machine. It sinters material at three locations nearly simultaneously using only a single beam. In parallel mode, the OPM makes optimal use of the laser unit by targeting multiple locations nearly simultaneously, dramatically increasing productivity. The video below shows the machine using parallel mode technology to print a workpiece in maraging steel:

Christian states that parallel mode was not yet available when he took delivery of the machine. Installed a couple months later, parallel mode did exactly as claimed, reducing laser time dramatically.

On other machines, because laser sintering equipment must take fumes and shape deviation into consideration when generating the laser path, the laser unit is not necessarily used at full capacity during processing. “Although fumes and deviation are always taken into consideration, by sintering multiple locations, you are not influencing the fume buildup in the vicinity of the other laser targets. At its most fundamental level, this is why systems with dual or quad lasers can be used. However, Sodick’s technology uses this same principle with regards to the capacity of a single laser,” says to Tom Hipp, OPM national product manager at Sodick.

In addition to efficiency considerations, parallel mode is suited to a wide variety of applications and can be used not just to create replicas of the same part, but also to produce singular large parts in less time. “Parallel mode doesn’t have a strict ‘maximum’ size,” according to Hipp. The OPM250L has a 250- × 250-mm work envelope and parallel mode will operate throughout the production of a workpiece that size.

Unlike multi-beam designs, which often use separate work envelopes, parallel mode is not limited to one beam per quadrant. This means that a workpiece covering only one part of the work table will benefit from parallel mode just as much as if it had covered the entire table.

“In general, multi-beam systems often align their beams to fit limited work envelopes. However, as with any single-beam design, the OPM work envelope is defined by what the single laser unit can reach. That means, because the single laser unit can reach the full work area, parallel mode can reach the full work area. This makes sense when you consider that parallel mode is simply the optimized use of the same laser,” says Hipp.

Parallel mode also benefits from a recently upgraded fume collector with a higher capacity design that is issued standard with the OPM. It lasts about three times longer than the original design, allowing it not only to run longer between maintenance cycles, but also to easily accommodate the fumes produced by parallel mode’s increased productivity.

Together, these advancements help to optimize the quality of the metal 3D printing process, which includes programming of the laser, allowing users to accurately print finished, high-density parts that may not be possible otherwise.

Related Content

Additive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

Read More3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

Read More3D Printed NASA Thrust Chamber Assembly Combines Two Metal Processes: The Cool Parts Show #71

Laser powder bed fusion and directed energy deposition combine for an integrated multimetal rocket propulsion system that will save cost and time for NASA. The Cool Parts Show visits NASA’s Marshall Space Flight Center.

Read More3D Printed Titanium Replaces Aluminum for Unmanned Aircraft Wing Splice: The Cool Parts Show #72

Rapid Plasma Deposition produces the near-net-shape preform for a newly designed wing splice for remotely piloted aircraft from General Atomics. The Cool Parts Show visits Norsk Titanium, where this part is made.

Read MoreRead Next

Profilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More