Staying Focused on the Promise of AM

For this company, realizing that promise is a long-term undertaking. In the short term, it involves sometimes saying no.

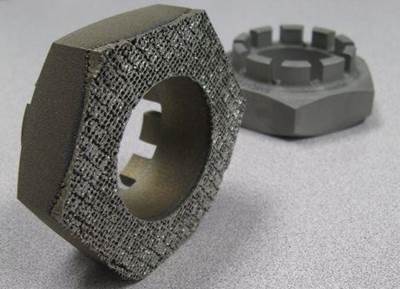

I saw a great mentor/protégé moment during my visit to Imperial Machine & Tool, an established machining business now earning 5 percent of its sales from additive production work done on two machines from SLM Solutions. Christian Joest, part of this shop’s owning family, was concerned about a situation that would concern any manufacturing business leader: Valuable machines—specifically, the two metal AM machines—were sitting idle. There was opportunity to put them to work. He openly wondered: Why not use the availability on these machines to serve companies wanting basic metal 3D printing work, such as prototype parts?

Chris Joest, Christian’s father and Imperial’s president, had a simple answer. He said, “It’s not what we do.” To him, the promise of additive manufacturing is not prototypes, not short-term work, but ongoing production. In fact, the promise is production of new components that can’t be made any other way. Staying focused on that promise is important, he says, even if that promise is slow to be realized, and even if it takes time and commitment to help customers develop this kind of work.

I see the younger man’s point. Imperial has been, and still is, a machining business. The old adage says your machine tool isn’t making money if it’s not making chips. Similarly, a 3D printer isn’t making money if it’s not making layers. On either type of machine, there is a good argument for taking the work you can get.

But then—and this has taken me longer—I can now see the father’s point as well. Indeed, this point applies to more than manufacturing. Whatever you have, it also has you, and whatever you do, it is doing something to you. Every step aims at a destination, so where do you want to go?

Consider this: If Imperial were to go down the road of doing one-off 3D printing work (worthwhile work, to be sure), then that would mean entering relationships with customers wanting this work. It would mean becoming connected to these companies, and making and keeping promises to them. And though there is nothing wrong in any of this, all of it together would divert the company from seeking the work it wants. It would leave the company potentially too distracted to commit when the opportunity for that work presents itself, or even too distracted to notice when the first glimpse of that opportunity appears.

The phrase “addition by subtraction” describes something real. What we leave out enhances the effectiveness of what remains. And increasingly, I wonder if this isn’t the most powerful form of addition there is. For the organization or the individual with something of real worth to offer, there are many opportunities. There are many things to which to say yes. And saying yes produces an effect—it leads to activity, variety and the answers to pressing needs.

But Chris Joest’s point is this: The way into some kind of next-level success involves a different answer. It involves saying no. Indeed, the way forward—far forward—entails learning how and when to say no, and coming to recognize just how surprisingly often this answer is the right one.

Related Content

8 Cool Parts From Formnext 2024: The Cool Parts Show #78

End-use parts found at Formnext this year address various aspects of additive's advance, notably AM winning on cost against established processes.

Read MoreBeehive Industries Is Going Big on Small-Scale Engines Made Through Additive Manufacturing

Backed by decades of experience in both aviation and additive, the company is now laser-focused on a single goal: developing, proving and scaling production of engines providing 5,000 lbs of thrust or less.

Read MoreVulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

Read MoreActivArmor Casts and Splints Are Shifting to Point-of-Care 3D Printing

ActivArmor offers individualized, 3D printed casts and splints for various diagnoses. The company is in the process of shifting to point-of-care printing and aims to promote positive healing outcomes and improved hygienics with customized support devices.

Read MoreRead Next

Learning Curve

A manufacturer that has succeeded for three generations expects additive manufacturing to be part of the reason why it will succeed in the fourth. One year into its investment in the technology, here is the company’s experience so far.

Read MoreMetal 3D Printing in a Machine Shop? Ask the Marines

A hybrid system combining metal 3D printing with machining gives the Marine Corps perhaps its most effective resource yet for obtaining needed hardware in the field. It also offers an extreme version of the experience a machine shop might have in adding metal AM to its capabilities.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read More