LPBF

Support Structures and Build Layout Lead to Series of Fails — AM: Why the Failure? #4

A 3D printed piston crown illustrates the iterative path to success often part of laser powder bed fusion additive manufacturing.

WatchMetal 3D Printed Part Should Be Flat, Has Bubble — AM: Why the Failure? #1

What should have been a straightforward application of laser powder bed fusion to make a simple component in 316L stainless steel turned into a printing fail. See why the failure happened.

WatchMaking a Slow Decision on a Fast Technology: Evaluating the Business Case for Multi-Laser Powder Bed Fusion

A data-driven approach to laser powder bed fusion reveals how companies can get cost out of parts and match productivity to customer requirements. Part Three of a three-part series.

Read MorePushing Laser Powder Bed Fusion into New Realms of Productivity

The Betatype technology stack supports businesses looking to expand on the potential of additive manufacturing for series production through design-led thinking and unique optimization algorithms to maximize the capacity of LPBF systems.

Read MoreDMLS or Polyjet? A Hands-On Comparison to Produce Prototype Mold Inserts

The development phase of creating injection molded parts and inserts often requires the production of small-quantity prototypes. This moldmaker compared two different AM technologies to produce prototype mold inserts made from tool steel and polypropylene photopolymer.

Read MoreDesktop Metal Delivers Mid-Volume Metal 3D Printing System

Shop System is said to achieve exceptional surface finish parts with rich feature detail at speeds up to 10 times faster than those of legacy 3D powder bed fusion technologies.

Read MoreSpeed Is Relative in AM: A Data-Driven Comparison of Multi-Laser Powder Bed Fusion and Binder Jet Processing

There is a difference between the effective print speed and the actual cost to produce the component with AM. John Barnes compares binder jet processing with powder bed fusion for metal parts.

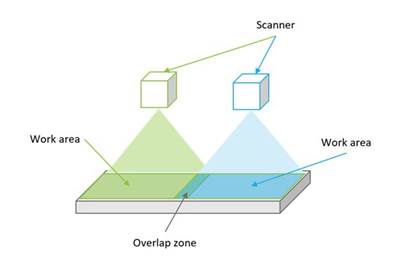

Read MoreA Technical Economic Perspective on Multi-Laser Powder Bed Fusion 3D Printers

When it comes to laser-based powder bed fusion, more lasers do not always lead to greater productivity. Considerations for multi-laser 3D printing.

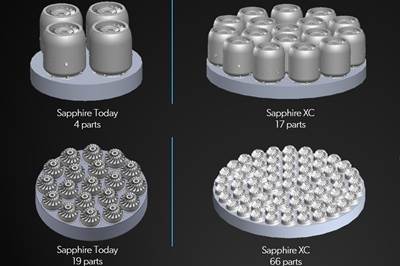

Read MoreLarge-Format Metal 3D Printer Will Let Users Keep the "Recipe" But Gain Productivity

The forthcoming Sapphire XC metal powder bed fusion system from Velo3D adds size and speed, but requires no new process development for existing part designs.

Read MoreCimquest Exclusive Distributor for Xact Metal’s LPBF 3D Printer

Printer is geared toward enterprise shops and manufacturers.

Read More