LPBF

JEOL E-Beam Metal AM 3D Printer for Improved Productivity

This electron beam melting powder bed fusion machine is said to achieve high productivity, reproducibility and accuracy due to its automatic correction of focus and spot shape.

Read MoreUniformity Labs’ Stainless Steel Powders Deliver Improved Mechanical Properties

The powders are said to deliver improved mechanical properties at much higher throughput in laser powder bed fusion (LPBF) additive manufacturing.

Read MoreMicroturbine Relies on 3D Printed Housing to Preheat Fuel

The aluminum housing designed with nTopology and made on a Velo3D laser powder bed fusion system helps realize what its creators say will be the highest-power-density small turbine yet produced.

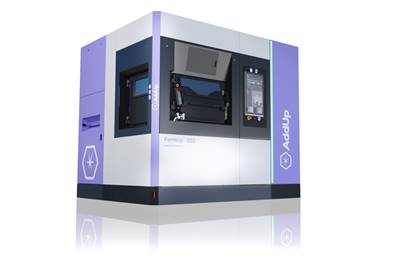

Read MoreAddUp and WBA Collaborate on Additive Manufacturing for Toolmaking

As part of the partnership, a FormUp 350 New Generation powder bed system from AddUp will be installed at the WBA Demonstration Tool Shop.

Read More10 Ways Additive Manufacturing Reshapes a Production Facility (Forget What You Know About Factories)

Sintavia’s purpose-built facility for powder bed fusion of aircraft components illustrates fundamental ways the plant is different when 3D printing is the operation.

Read MorePostProcess, Alphacam Partner to Expand Access to Automated 3D Postprinting in Germany

Alphacam’s in-house printing service — which manufactures components with FDM, PolyJet, LPBF, BMD, DLP/P3 and SAF technology — will also utilize the PostProcess solution for its own operations.

Read MoreAdditive Manufacturing for Rail Industry Is Gaining Traction at Neighborhood 91

Locomotive manufacturer Wabtec is the first tenant of Pittsburgh’s N91 additive manufacturing ecosystem, where the company is ramping up production via laser powder bed fusion.

Read MorePrecision LPBF Improves Watch Component Part Performances

Partnering with AddUp has enabled watch part maker Kif Parechoc to use laser powder bed fusion to manufacture parts with improved mechanical performance using less material.

Read MoreVideo: What Is Laser Powder Bed Fusion (LPBF)?

Laser powder bed fusion is likely the most widely used metal additive manufacturing process. Here is how it works, including benefits, issues to consider and applications for this 3D printing technology.

WatchConcept Machine Tool Appointed Distributor for Farsoon Technologies

Concept Machine will serve as exclusive distributor for Farsoon’s metal and plastic laser powder bed fusion 3D printers and additive manufacturing products through nine states for sales, service and consumables.

Read More