Editor’s note: As metal additive manufacturing (AM) is increasingly adopted for production, the two technologies coming to the forefront are powder bed fusion (PBF) and binder jetting. But how do they stack up? Can binder jetting exceed the productivity of multi-laser PBF? Are the design advantages the same? Does one process make greater economic sense than the other? This article is the first in a contributed series authored by John Barnes of the Barnes Global Advisors exploring these issues. Read Parts Two and Three. —Stephanie Hendrixson

As any fan of Austin Powers could tell you “laser beams” are awesome, with the implication that more is always better (in terms of both sharks and laser beams). In this series, we will not be addressing lasers on sharks, but we will dip our toe into the international mystery of when and why multiple lasers make sense for powder bed fusion (PBF) 3D printing.

Laser proliferation began around 2015 when the first twin laser systems came onto the market. The SLM 280HL was the first machine fitted with a twin laser arrangement which immediately impacted the productivity of the SLM280 output. While there were obvious commercial benefits, e.g. productivity, new technical questions arose which required attention prior to production use.

We will be using “productivity” a lot in this discussion, and unlike the comical reference to Austin Powers, we take this quite seriously. The Organization for Economic Co-operation and Development (OECD) defines productivity as “a ratio between the output volume and volume of inputs.” It is the measure of how efficient inputs, lasers in our scenario, are being used to produce a level of output, i.e. parts. If adding a second laser increases the cost of the system without increasing its output, it would decrease productivity. Naturally, our desire as users is to increase parts produced per unit time and reduce cost per part. Therefore, let us take a little dive into the scenarios where a multi-laser 3D printer makes good business sense.

Why a Multi-Laser 3D Printer?

Multiple lasers enable larger powder bed systems by spatially separating the lasers to increase coverage or enabling the lasers to reach a larger area. The immediate benefit to applying more lasers in large powder beds is the ability to make larger parts.

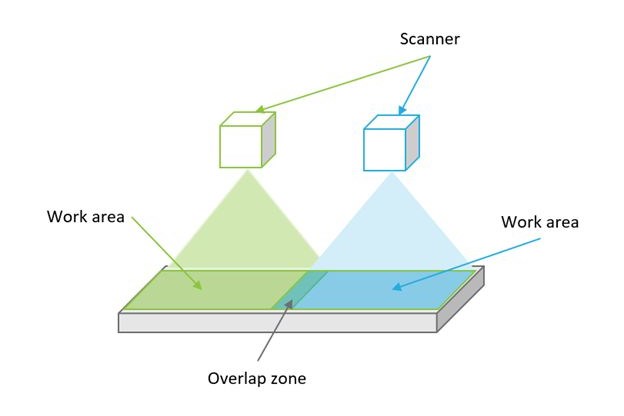

Multiple lasers can also increase productivity, but it is not a given that a multi-laser setup automatically equates to higher productivity. For that we introduce the next term called overlap. Overlap is the region two lasers can share on the powder bed area (Figure 1). More overlap tends to be useful in increasing productivity. Less overlap tends to be useful in making the same number of lasers cover a greater area; this is specifically useful for making larger parts.

Chart 1: Adding lasers to a powder bed fusion system introduces overlap, work areas that two or more lasers can share. More overlap can increase productivity, while less can help build larger parts. All Images: The Barnes Global Advisors

With the advent of overlap, engineers began to discover that two lasers “stitching” on a single part could create unpredictable results. Without going into a lengthy discussion of structural mechanics, allowing two lasers to make one part has historically been discouraged, especially in highly regulated industries. However, systems with reasonable overlap coverage enable production engineers to assign lasers to build individual parts. So, in this instance, multiple lasers with good overlap prevailed.

Quantifying the Multi-Laser Economic Impact

The Barnes Global Advisors (TBGA) performed an economic exercise to quantitatively assess the impact of various productivity improvements, including increasing lasers, on two exemplar parts: a control arm and a gearbox housing. For each, we designed a part and performed productivity and cost estimates including the full value chain from powder through to a production-ready assembly; i.e., parts were heat treated, inspected and critical interfaces were machined.

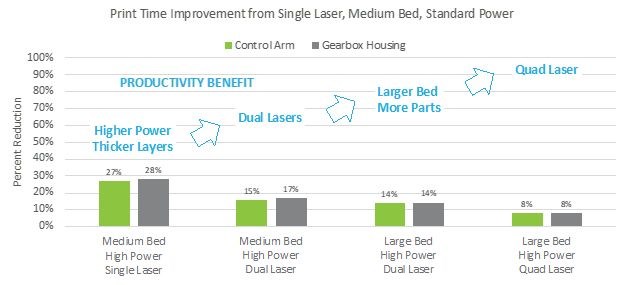

Below, Figure 2 shows the productivity results for both parts through the 3D printing stage only, where we can clearly see the benefits of bed size, parameters and laser power.

Figure 2: Percent reduction in 3D printing time from a medium bed, standard power and single-laser system with productivity benefit describing what changed from previous category.

Figure 3 shows the cost reduction of a part in a mix of control arms and gearbox housings. You will note that the order of printer configuration changed from Figure 2 which shows the importance of the supply chain and total part cost, not only print speed.

Figure 3: Total part cost broken down by material, printing and postprocessing with the productivity attribute describing what changed from previous category.

Key Observations

In performing this study we observed that regardless of part size, print productivity benefited from each improvement iteration.

Part cost did not see the same order of magnitude change as the 3D printing time reduction. Why? We effectively reduced our 3D printing cost, but the production rate of printed parts was not increased enough to see similar benefits down the processing value chain.

Laser power and parameters are also important to factor in alongside bed size and laser quantity. In our study, we factored additional benefit from parameters that would reduce our finished part cost: Dual versus single laser can net an overall production cost reduction of 63%, while quad versus single laser can net a 72% production cost reduction.

We like to think of AM as being automated and very productive. While in an economic sense it is perhaps more automated than some legacy manufacturing, it is inherently still a batch (not a continuous) process; in fact, the AM value chain is generally a series of batch processes. These points are addressed in a science called “production learning curves”; here is a very good article to learn about them. To eke out additional productivity or efficiency we must appreciate the entire supply chain, just as design for additive manufacturing (DFAM) would prescribe. For example, if my printer produces more parts which increases the batch going into heat treatment, the per-part price decreases. The cost of running the furnace is the same if there are five or ten parts.

Key Aspects of the Multi-Laser Business Case

Laser proliferation in PBF printers will continue as original equipment manufacturers roll out systems with ever-increasing numbers of lasers. Evaluating the benefits of multi-laser printers requires a keen focus on your specific business goals and technical requirements. One can argue that there is no one single “right” machine for every part. Selecting the right 3D printer requires careful study. Your unique requirements will drive your final selection. Some questions to consider:

- What are the size and dimensions of the parts you want to build? One or two big parts or many smaller parts?

- How big is the overlap region or coverage?

- How many lasers are useful? Is it more productive? Can you make your downstream processing more efficient?

More is not always better. Better is defined by your requirement. Are you making one large part or many smaller parts? Careful selection of equipment is required to achieve a positive business case. Properly employed, multi-laser systems can enable manufacturers to increase productivity and part size.

In Part Two of this series, we will analyze the Venn diagram of binder jetting and powder bed fusion (which could be titled, “Why can’t we all just get along?”). We believe that the two processes have their own merits and the design space for either technology has little overlap. Like Ricky Bobby said, “I want to go fast,” but speed is relative in AM.

About the Author

John E. Barnes

John has a 25+ year career in product development and aerospace with Honeywell, Lockheed Martin Skunk Works™, Australia’s CSIRO, and Arconic (formerly Alcoa and RTI International Metals). He’s been involved in metal additive manufacturing throughout this career beginning in the late 1990s where he was part of the Sandia National Labs LENS™ CRADA. Since then, he has been in and around additive manufacturing working both technical and business cases for implementation and development efforts in materials, powders, processing and printing to mature the technology for applications.

John is recognized internationally for contributions to additive manufacturing, product development, and leadership in engineering. His groups boast world firsts in medical, therapeutic and aerospace additive manufacturing. He is a materials engineer by background but has developed expertise in manufacturing, airframe structures, gas turbines and low observables. He is currently an adjunct professor at Carnegie Mellon University and RMIT University, as well as an adjunct senior research fellow at Monash University. In 2014, he was Purdue University’s Materials Engineer of the Year, and in 2017, he was invited to join the Additive Manufacturing Technical Community as an SME AM Advisor based upon active industry contributions, reputation, and personal commitment to expand the use of additive manufacturing.

Related Content

3D Printed Spacer Grids for Nuclear Power: The Cool Parts Show #79

Westinghouse Electric Company is exploring laser powder bed fusion as a means of manufacturing spacer grids, critical parts of the fuel rod assemblies used in pressurized water reactors.

Read MoreBeehive Industries Is Going Big on Small-Scale Engines Made Through Additive Manufacturing

Backed by decades of experience in both aviation and additive, the company is now laser-focused on a single goal: developing, proving and scaling production of engines providing 5,000 lbs of thrust or less.

Read MoreAdditive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

Read MoreNew Zeda Additive Manufacturing Factory in Ohio Will Serve Medical, Military and Aerospace Production

Site providing laser powder bed fusion as well as machining and other postprocessing will open in late 2023, and will employ over 100. Chief technology officer Greg Morris sees economic and personnel advantages of serving different markets from a single AM facility.

Read MoreRead Next

Video: The Impact of Part Orientation on Cost and Build Time in AM

A different build orientation might mean fewer layers and less support structure, though the part might need to be redesigned to take advantage of this different orientation.

Read MoreSeries: Installing a Metal 3D Printer

A five-part series documents one manufacturer’s experience and lessons learned while installing a powder-bed fusion metal 3D printer.

Read MorePushing Laser Powder Bed Fusion into New Realms of Productivity

The Betatype technology stack supports businesses looking to expand on the potential of additive manufacturing for series production through design-led thinking and unique optimization algorithms to maximize the capacity of LPBF systems.

Read More