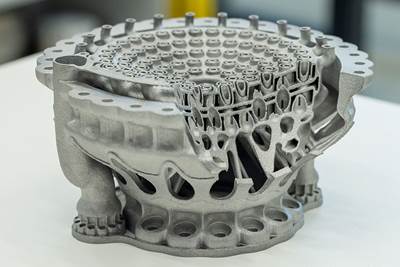

LPBF

AMALLOY Is UAE’s First Locally Developed 3D Printing Alloy

The Technology Innovation Institute says its AMALLOY aluminum alloy powder registers 33% greater strength without compromising on ductility when compared to commercially available AlSi10Mg alloys.

Read MoreMultimodal Powders Bring Uniform Layers, Downstream Benefits for Metal Additive Manufacturing

A blend of particle sizes is the key to Uniformity Labs’ powders for 3D printing. The multimodal materials make greater use of the output from gas atomization while bringing productivity advantages to laser powder bed fusion and, increasingly, binder jetting.

Read MoreVideo: Multimodal Powders for Metal 3D Printing

Rather than uniform particle diameters, multimodal powders combine particles of different sizes. In this video, how and why Uniformity Labs produces multimodal metal powders for additive manufacturing.

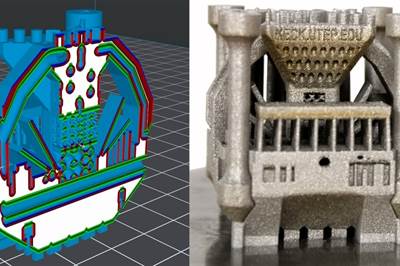

WatchDyndrite Joins NMIS to Advance 3D Metal Manufacturing Research

Dyndrite has joined NMIS to help develop build recipes and shareable knowledge in materials process development across all major laser powder bed fusion OEM file formats.

Read MoreAddUp Adds Constellium’s Aheadd CP1 Aluminum Alloy to Material Portfolio

The Aheadd CP1 aluminum alloy was developed by Constellium for the needs of additive manufacturing by laser powder bed fusion specifically for high-performance and lightweight applications.

Read MoreAmerica Awards Research Funding to Colorado School of Mines

The project team will investigate cross-platform consistency in laser powder bed fusion technologies.

Read MoreAddUp Participates in $1.5M USAF Research on IN-718 Additive Manufacturing

AddUp is partnering with Zeda to provide critical project support to provide the USAF with a set of manufacturing guidelines to maximize the capabilities of LPBF to meet fleet readiness and sustainment goals.

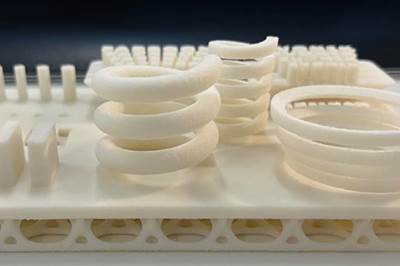

Read MoreFarsoon, Evonik Collaborate on INFINAM Thermoplastic Copolyester

INFINAM TPC (thermoplastic copolyester) is a ready-to-use, elastomer-grade material for powder bed fusion 3D printing that can enable customers to unlock new markets and applications.

Read MoreVulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

Read MoreMicro Robot Gripper 3D Printed All at Once, No Assembly Required: The Cool Parts Show #59

Fine control over laser powder bed fusion achieves precise spacing between adjoining moving surfaces. The Cool Parts Show looks at micro 3D printing of metal for moving components made in one piece.

Watch