LPBF

New Zeda Additive Manufacturing Factory in Ohio Will Serve Medical, Military and Aerospace Production

Site providing laser powder bed fusion as well as machining and other postprocessing will open in late 2023, and will employ over 100. Chief technology officer Greg Morris sees economic and personnel advantages of serving different markets from a single AM facility.

Read MoreUniFuse IN625 Nickel Alloy for LPBF for Higher Throughput, Superior Mechanical Properties

Uniformity Labs says its IN625 nickel alloy powder provides more repeatable and reproducible mechanical properties across the build bed, printed at far higher throughput.

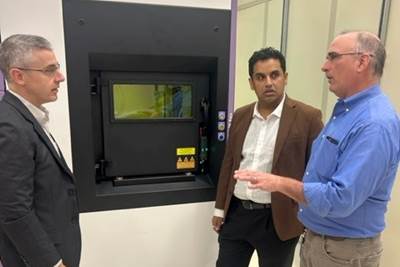

Read MoreZeda Collaborates With AddUp for Aerospace, Medical Additive Manufacturing

The first of eight AddUp FormUp 350 powder bed fusion machines deployed has been installed at Zeda to support its growth in the aerospace and medical sectors.

Read MoreSenvol Commercializes Siemens Energy’s Material Databases

Databases for Ti64, Inconel 625 and Inconel 718 were generated by Siemens Energy on its laser powder bed fusion machines. Although the data was initially intended exclusively for internal use, the company recently decided to make the data commercially available.

Read MoreAmerica Makes’ Project Call for LPBF Cross-Platform Consistency

Project entry requirements include registration at TRX Industry Day at UTEP by Wednesday, March 8, 2023; with the submission deadline set for Friday, April 7, 2023, by 5 p.m. ET.

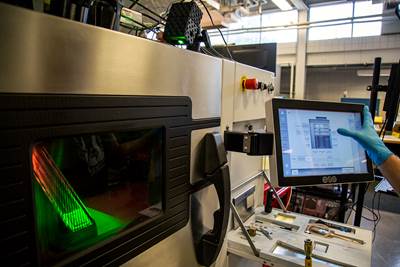

Read MorePhase3D’s Early Adopter Program for Real-Time AM Part Quality Inspection

Company says 3D printing in-situ inspection system detects defects in real-time, enabling users to fully monitor additive manufacturing operations for both laser powder bed fusion (LPBF) and binder jetting processes.

Read MoreAdditive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

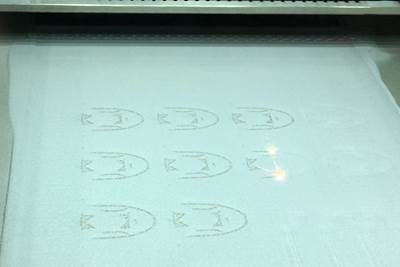

WatchUniformity Labs Creates Ultralow Porosity Aluminum Powder for LPBF

Uniformity Labs’ UniFuse AlSi10Mg aluminum powder is the latest in the company’s range of ultralow-porosity metal powders that are said to deliver high-speed, high-quality parts repeatedly and at scale for metal additive manufacturing.

Read MoreThe Power of the Particle: Characteristics That Affect Powder Bed Fusion AM

A recent webinar explores the influence of powder properties and the direct effect they have on AM build outcomes. Detailed are several methods for measuring characteristics of particle shape, size and surface chemistry during the feedstock life cycle.

Read MoreUniformity Labs Develops Ultralow Porosity Stainless Steel Powder for LPBF

The ultralow porosity UniFuse 316L 90-micron stainless steel powder features corrosion resistance, high flexibility and excellent mechanical properties at extreme temperatures.

Read More