LFAM

Europe Seeks to Develop the Jack-Of-All-Trades of Additive Manufacturing

Supported by the European Union's Horizon 2020 Research and Innovation Program, the Kraken project team aims to develop an AM machine that can process large functional components ranging to 20 meters in length, made of plastics, metal or both.

Read MoreThermwood 3D Prints Large Boat Hull Pattern

Thermwood’s large-scale additive manufacturing (LSAM) technology enabled the fabrication of a 3,000-lb plug for a boat hull mold. The project illustrates how 3D printing could help reduce fabrication costs for marine composites.

Read MoreVideo: 3D Printing at Local Motors

3D printing plays multiple roles at the company’s Knoxville microfactory, from prototyping to the production of parts for autonomous vehicles.

WatchAdvantages of Wire Over Powder in Additive Manufacturing

Gefertec says its wire-fed additive manufacturing systems can overcome existing process limitations of powder-fed systems.

Read More3DMonstr Increases Size Offerings with Super-Rex Line

The new line of 3D printers comes in sizes as large as 3 m³.

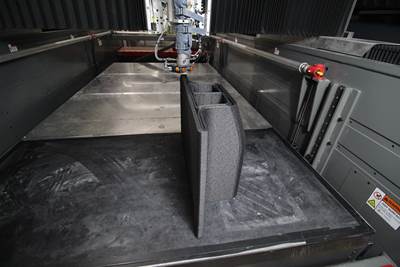

Read MoreLarge-Format 3D Printer Builds Carbon Fiber-Reinforced Submarine

Oak Ridge National Laboratory (ORNL) has teamed up with the U.S. Navy to 3D print a demonstrator submarine hull for Navy SEALs application.

WatchChecking in with Additive Engineering Solutions

Partnerships continue to be critical to the success of the first commercial user of BAAM technology.

Read MoreOhio Business Sees Big Possibilities in BAAM for Tooling

A new startup built around a large-scale 3D printer aims to offer short lead times for large industrial tools.

Read MoreVideo: 3D-Printed Excavator at ConExpo

The cab, arm and heat exchanger were all 3D printed on the first excavator to feature major components produced additively.

Read MoreFrom CAD File to Composite Part in 72 Hours

This Akron company focuses on large-format 3D printing for tooling, including composites layup tooling. Among the advantages are short lead times and adaptability to changes.

Read More