Checking in with Additive Engineering Solutions

Partnerships continue to be critical to the success of the first commercial user of BAAM technology.

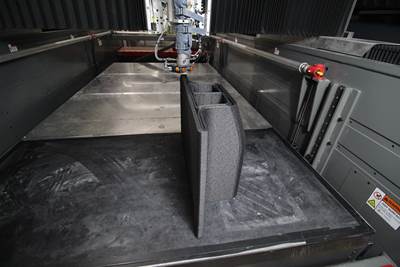

“I often tell people that we’re only three full-time employees here at AES, but we have the support of many,” says Andrew Bader, cofounder of Additive Engineering Solutions (AES) during an open house at the company’s Akron, Ohio, facility on June 1. AES, which owns one of only a dozen or so Big Area Additive Manufacturing (BAAM) machines in existence, is the first and only commercial user of this technology thus far. Additive Manufacturing magazine has written about AES previously, and the company was the subject of the cover story of our May issue.

In part the open house was a celebration of the facility’s latest addition, a five-axis router from Quintax equipped with a Fagor CNC. This piece of equipment was not there last time AM visited. In fact, it was installed just nine days prior to the open house. Its arrival means that AES now has 3D scanning (by way of Faro equipment), 3D printing and finishing capabilities in-house, and no longer has to rely on outside firms for machining BAAM parts to a smooth surface.

But even more so, the event was a celebration of partnerships. In a welcome speech to attendees, Bader recounted AES’s journey, from his meeting fellow cofounder Austin Schmidt in 2015, to their pitching the idea to Bader’s family (owners of Ohio Gasket & Shim [OGS] located just across the parking lot) in 2016, to opening the doors of the Akron facility in January of 2017. OGS continues to be a significant source of support for AES, in everything from IT support to helping with the setup and running of the new router.

But beyond the help next door, the business relationships AES has formed with local organizations have been key to its success. The company has been able to find 90 percent of the products and services it needs in the state of Ohio, says Schmidt. This includes both the BAAM printer (manufactured by Cincinnati Inc. near the city of the same name) and the Quintax router (produced in Stow, a 10-minute drive from AES).

In an Industry 4.0 world where cloud computing and digital manufacturing are on the rise alongside communication technologies, it’s still impossible to discount the value of physical proximity and face-to-face meetings for collaboration and technology advancement. Joe Lettieri, program manager for Goodyear’s innovation group, made this point to attendees. “There’s still a tremendous value in a conversation over coffee or an impromptu meeting around a whiteboard,” he says.

Having AES’s BAAM capability nearby is a boon to manufacturers in the Akron area, including Goodyear. But it’s also good for the industry, argues Lettieri, citing the importance of collocating critical resources and people to “remove barriers between minds” and help to advance AM technology.

Face-to-face meetings also drive business, a point that was illustrated by a series of parts on display (though not available for photography) during the open house: several 3D-printed sections of a 45-foot-long boat mold. This job came about because of a chance meeting between AES and the customer in Cincinnati Inc.’s booth at Rapid 2017. Three weeks later, the mold was nearly complete.

This nimbleness and flexibility is part of what makes small startups like AES critical to the AM industry. Even large companies like GE need small companies, noted Kirk Rogers, additive manufacturing leader at GE Additive. Rather than viewing small companies like AES as competition, Rogers says the goal is “a symbiotic relationship where we help them grow, and they help us with technology advancement.”

“Small companies come up with great ideas, they move quickly, they change the industrial landscape faster than a big company like GE can,” says Rogers. Both stand to benefit, and success means a win for the industry at large.

Related Content

3D Printed Preforms Improve Strength of Composite Brackets: The Cool Parts Show Bonus

On this episode, we look at a pin bracket for the overhead bin of an airplane made in two composite versions: one with continuous fiber 3D printed reinforcements plus chopped fiber material, and one molded from chopped fiber alone.

Read MoreLouisville Slugger Uses Formlabs Technology to Accelerate Innovation

Louisville Slugger relies on Formlabs’ Form 3 stereolithography 3D printer to create both prototypes and manufacturing aids for designs of the composite and aluminum bats swung by youth and collegiate players.

Read MoreAdvancing Additive Manufacturing With a CATCH and Release Approach

Solutions for energy efficiency, sustainability, part repair and more are developing at Siemens’ Charlotte Advanced Technology Collaboration Hub (CATCH) in North Carolina.

Read MoreTo Improve Performance of Compression Molded Composites, Add 3D Printed Preforms

9T Labs' Additive Fusion Technology enables the manufacture of composite structures with as much or as little reinforcement as is necessary, using 3D printed continuous fiber preforms to add strength just where needed.

Read MoreRead Next

Ohio Business Sees Big Possibilities in BAAM for Tooling

A new startup built around a large-scale 3D printer aims to offer short lead times for large industrial tools.

Read More3D-Printed Tooling Offers Durability for Precast Concrete

As an alternative to wooden tooling, 3D-printed forms for precast concrete are proving to be more durable and better able to support a large-scale renovation project.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More

.jpg;width=70;height=70;mode=crop)