LFAM

Laser Cutting Specialist Develops Large-Travel Additive Approach

For SLM of parts that are multiple feet long, this machine’s build chamber travels throughout the machine area to 3D print the solid part one section at a time.

WatchPostprocessing Composite Tooling: Machining, Coating or Combination Strategy?

A project testing the surface finishing options for composite tooling reveals insight about machining and coating strategies.

Read MoreEight-Axis Robotic System Prints Composite Parts

This concept machine leverages robotics to 3D print in eight axes.

Read More7 Important Implications of the New Stratasys Production Demonstrators

One working machine concept expands the build size and speed for FDM. Another performs robotic 3D printing in composite material. Here is what these two concepts suggest about the advance of additive manufacturing into industrial production.

Watch3D Printing Autoclavable Composite Molds

A polymer AM research team at ORNL reports it has successfully fabricated autoclave-capable carbon fiber composite molds, manufactured using large-scale 3D printing/additive manufacturing.

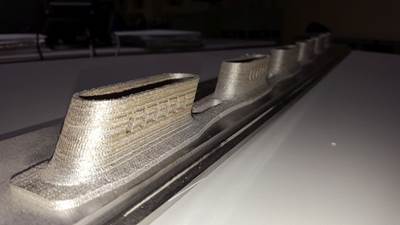

Read MoreAM System Using TIG Welding and Robot Relies on Flexible Enclosure for Gas Protection

The WAAM system has demonstrated the ability to produce a titanium aircraft part, but titanium in particular requires protection against oxidation.

Read MoreLockheed Martin: Importance of Closed-Loop Control in AM

Process repeatability will enable the satellite maker to apply additive manufacturing to the production of critical parts.

Read MoreThe Possibilities of Electron Beam Additive Manufacturing

With dual-wire material feed now allowing for options including blended metal alloys, the metal-deposition process for large-part additive manufacturing continues to forge ahead.

Read MoreVideo: Microfactories, Large-Scale Machines and 3D Printers in Schools

Lonnie Love of Oak Ridge National Laboratories discusses the various factors that will contribute to the advance of additive manufacturing.

WatchVideo: Toolingless Manufacturing and the Impact of Additive on Automotive Production

Jay Rogers of Local Motors discusses his company’s coming 3D-printed car and what it represents.

Watch