LFAM

Consortium Builds Ship Propeller Via Wire plus Arc Additive Manufacturing (WAAM)

The robot-driven deposition technology has been successfully applied in a propeller application for the marine industry.

Read MoreThermwood and U.S. Navy Complete Validation for AM Marine Program

The validation program centered on printing an unclassified scale nose of a submarine using Thermwood’s Large Scale Additive Manufacturing (LSAM) system.

Read MoreWHAM Developer Appoints New CEO

Chip Storie is leading Ingersoll Machine Tools, developer of the Wide and High Additive Manufacturing (WHAM) system.

Read MoreCarbon Fiber Bike Frame Made Possible with Robotic 3D Printing

Arevo’s True3D printing process, which deposits carbon fiber towpreg using a robotic arm, enabled the creation of a bike frame design that would not have been possible otherwise.

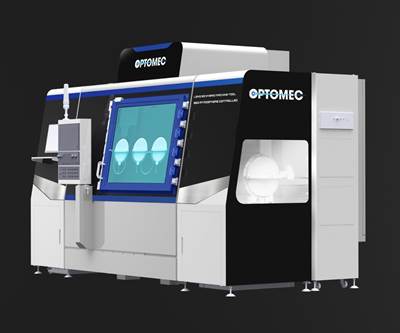

Read MoreOptomec Introduces LENS 860 Hybrid Controlled Atmosphere (CA) Metal 3D Printer

The large-format metal 3D printer's hermetically sealed build chamber supports hybrid manufacturing with reactive materials.

Read MoreVideo: LSAM Speeds Production of Concrete Tooling

Thermwood’s dual-gantry Large Scale Additive Manufacturing (LSAM) 3D printer with CNC router printed and trimmed a large concrete tool with fewer setups.

WatchGTarc Machines 3D Print Near-Net-Shape Metal Parts

The system uses a wire-welding process to create metal parts at production speeds.

Read More3D-Printed Tooling Offers Durability for Precast Concrete

As an alternative to wooden tooling, 3D-printed forms for precast concrete are proving to be more durable and better able to support a large-scale renovation project.

Read MoreThermwood Offers Large Scale Additive Manufacturing (LSAM) Line

Rapid 2018: The systems can 3D print and trim large, near-net-shape reinforced thermoplastic composite parts.

Read MoreBigRep, BASF Sign Strategic Partnership Agreement

The large-format 3D printing technology provider and the global chemical company will work together to develop materials and printers for industrial customers.

Read More