LFAM

A Resonant Harmony for Bell Casting and 3D Printing

When a 180-year-old bell foundry sought an alternate solution for expensive metal mold patterns, it turned to a 125-year-old company for a modern solution: large-format additive manufacturing.

Read MoreDigital Demo: Why LSAM?

Scott Vaal, Thermwood’s LSAM product manager, offers an overview of key aspects of the large scale additive manufacturing market. (Sponsored)

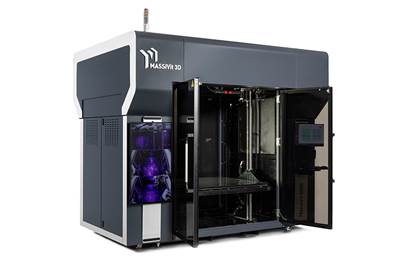

WatchMassivit 5000 Expedites Large-Scale 3D Printing

The Massivit 5000 is designed to dramatically expedite large-scale manufacturing, prototyping and tooling for the automotive, marine and rail industries.

Read MoreSiemens Automation Supports CEAD, Belotti Large-Format Hybrid Machine

The machines will be equipped with Siemens Sinumerik CNC for precise printing and milling.

Read MorePurdue University to Establish Thermwood LSAM Research Laboratory

Collaborative efforts like this can bring together diverse organizations that specialize in different aspects of an emerging technology and often produce results that none of the participants could possibly achieve on their own.

Read MoreExOne Acquires Freshmade 3D Assets

ExOne believes Freshmade 3D’s patented approach offers additional unique benefits and can help accelerate adoption of 3D printed sand tooling solutions.

Read MoreSafran, SLM Solutions Test Technology for Large Airplane Component

In a joint project, Safran Landing Systems and SLM Solutions tested selective laser melting to produce a component of a nose landing gear for a bizjet, marking a world first for a part of this size.

Read MoreThermwood Technology Ensures Complete Fusion for Large-Scale 3D Printing

LSAM also makes print temperature control completely automatic.

Read More10 Examples of 3D Printed Tooling

Additive manufacturing can aid conventional manufacturing through the production of tooling. This article showcases 10 clever uses of 3D printed tooling.

Read MoreBell Textron, Ingersoll Machine Tools Produce 3D Printed Rotor Blade Trim Tool

Collaborative effort successfully manufactured a 22-foot-long vacuum trim tool for production of main rotor blade components.

Read More