LFAM

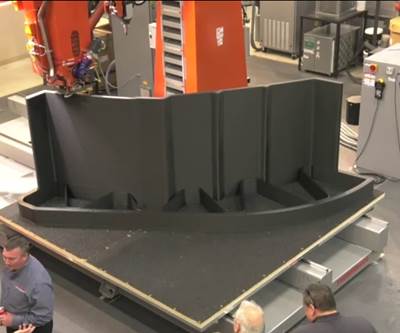

Inside Oak Ridge’s 3D-Printed Machine Tool Moonshot

The widespread outsourcing of large machine castings led a collaborative team at Oak Ridge National Laboratory to tackle the machine tool supply chain. The first step? 3D print the largest cast component.

Read MoreCommercializing Sand 3D Printing in the New Tech Belt

Youngstown-area Humtown Products supplies both conventional and 3D printed sand cores and molds to foundries around the world. But sand tools for castings may be only the beginning.

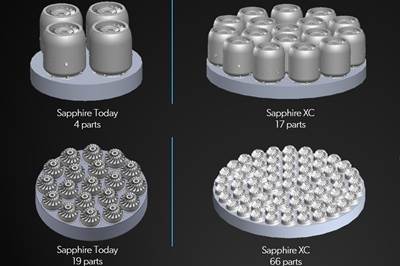

Read MoreLarge-Format Metal 3D Printer Will Let Users Keep the "Recipe" But Gain Productivity

The forthcoming Sapphire XC metal powder bed fusion system from Velo3D adds size and speed, but requires no new process development for existing part designs.

Read MoreVelo3D’s Sapphire XC Large-Format 3D Metal Printer Increases Throughput

Extra capacity, large-format printer can increase production throughput by five times and reduce cost-per-part by up to 75%, compared to its predecessor.

Read MoreBigRep Offers Turnkey Industrial 3D Printer Rentals

Leasing program is said to enable easy, flexible and affordable additive manufacturing.

Read More3D Printed Prefab Homes, Made from Composite and UL-Certified

Mighty Buildings wants to change the construction industry with prefabricated houses 3D printed on demand from thermoset polymer composite. Two such buildings have already been installed.

WatchCGTech Extends Simulation to Thermwood LSAM (Includes Video)

Large-scale additive manufacturing platform is the largest 3D printer yet simulated. Watch video for example of how simulation using program G-code catches an error that would otherwise lead to a failed build.

WatchParametric Design and 3D Printing Deliver Custom, Sustainably Manufactured Furniture

Model No. operates at the intersection of technology and design. Its custom furniture is made on demand through a combination of proprietary large-format 3D printers, sustainable materials and a sleek online storefront.

Read MoreBigRep Launches ABS, ASA Advanced Materials

BigRep is expanding its materials portfolio with versatile and impact-resistant ABS and weather- and UV-resistant ASA, aiming to open a new dimension for Large-Format 3D Printing in the automotive and consumer products industries.

Read MoreVelo3D Launches Large Format 3D Metal Printer with Knust-Godwin as First Customer

The next-generation Sapphire machine will print up to 1 meter in height, said to be the tallest laser-powder additive manufacturing system.

Read More