LFAM

3D Systems Acquiring Titan Robotics

Company says acquisition adds Titan’s extrusion technology to complement 3D Systems’ polymer technology portfolio, opening new market opportunities.

Read MoreThe Broad Promise of Large-Format AM: AM Radio #10B

3D printing makes very large parts easier to produce. Julia Hider and Peter Zelinski discuss the promise of additive manufacturing for big parts on the AM Radio podcast.

ListenVelo3D Ships First Sapphire XC to Aerospace Customer

The company’s newest and largest metal 3D printer is said to deliver bigger parts, productivity improvements and cost reduction for metal additive manufacturing

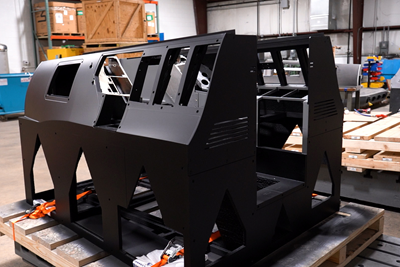

Read MoreVideo: Functional Excavator Features 3D Printed Parts

Oak Ridge National Lab's Project AME swapped an excavator's cab, stick and heat exchanger for 3D printed parts. Stephanie Hendrixson and Peter Zelinski get the scoop.

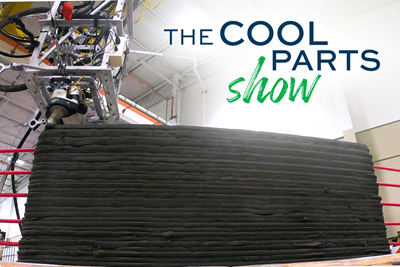

Watch3D Printed Concrete Is Key to This Smart Wall: The Cool Parts Show #40

The SkyBAAM cable-driven 3D printer creates opportunities for embedded functionality in concrete, as demonstrated in this episode of The Cool Parts Show.

WatchAirtech’s Dahltram Resins Qualified for Use on All CEAD AM Flexbot Platforms

The AM Flexbot is one of CEAD’s AM solutions, using Comau robots directly controlled by Siemens Sinumerik. It offers an option to combine 3D printing and milling into one automated process.

Read MoreAdditive Industries’ MetalFABG2 Features Modular, Scalable, Open Systems

All three series models offer modular, scalable, open systems to ensure maximum flexibility and enable configurations up to 11 modules.

Read MoreUsing Large-Format Additive Manufacturing for Serial Production

First tools, then production parts. This pattern with industrial 3D printing at small and mid sizes has now come to the biggest additive machines as well.

Read More10 Ways Additive Manufacturing Reshapes a Production Facility (Forget What You Know About Factories)

Sintavia’s purpose-built facility for powder bed fusion of aircraft components illustrates fundamental ways the plant is different when 3D printing is the operation.

Read MoreBigRep Pro Large-Format Printer Designed for All Stages of Manufacturing

The company says the printer is versatile to enable the production of full-scale, large parts, including functional prototypes, factory tooling, patterns, molds and end-use parts.

Read More