LFAM

BigRep Additive Manufacturing Technology for Faster Iterations, Production

Formnext 2022: BigRep’s printers are open-material systems, offering users more flexibility with filament options.

Read MoreMassivit 3D Expands Systems, Materials Portfolio to Automate, Speed Up Composite Production

Formnext 2022: These additive manufacturing systems utilize the company’s Cast In Motion technology, which is said to enable direct printing of complex molds using high-performance casting materials.

Read More3 Points About 3D Printing Large Parts We Can Learn From the Lunar Habitat (Video)

Ingersoll Machine Tools describes the capabilities and promise of large-scale additive manufacturing as seen in the 3D printed sections of the Rosenberg Space Habitat.

WatchFarsoon’s LPBF Systems for Large-Scale Metal Additive Manufacturing

The FS621M Pro-4, FS621M Pro-6 and FS621M-U-4 systems are said to offer huge potential in aerospace applications by lowering operational cost and enabling true industrial-scale series manufacturing.

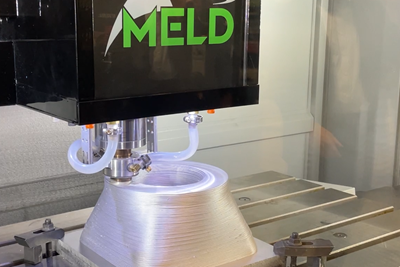

Read More3D Printing From Barstock Using Friction Stir Welding (Video)

A look at the Meld Manufacturing metal AM process. The machine tool in this video builds an additively manufactured part by rotating and compressing metal bar.

WatchFarsoon Assists in 3D Printing of Large Combustion Chamber

Farsoon’s technology also enables an accelerated design-validation cycle of 80% faster compared to conventional manufacturing processes.

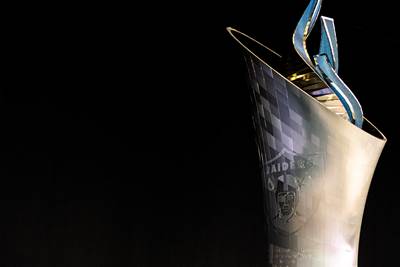

Read MoreThe World’s Tallest Freestanding 3D Printed Structure

Dimensional Innovations paired additive and subtractive manufacturing to create a monument for the NFL’s Las Vegas Raiders new stadium. The “never been done before” project resulted in the world’s tallest freestanding 3D printed structure.

Read MoreKAM Installs More EOS 3D Printers at Manufacturing Facility

KAM’s additive manufacturing capability now includes a comprehensive fleet of 20 large and midsize additive machines alongside 12 multi-axis CNC machine tools for an integrated advanced manufacturing supply chain.

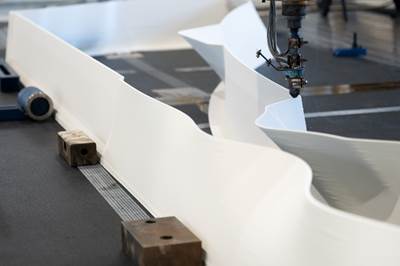

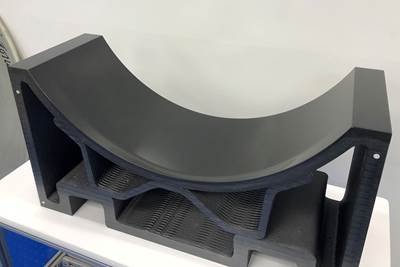

Read MoreAirtech Validates High-Temperature Polymer for Large-Format Tooling, Moldmaking

According to the company, the polymer is well suited for high-temperature applications such as hot forming tools, autoclave molds, oven molds and self-heated molds.

Read MoreRobot Deposition Makes Giant Industrial Mixer Blade: The Cool Parts Show Bonus

Wire arc additive manufacturing produces a large component formerly made through casting, and allows for redesign of its internal cooling geometry.

Watch