Basics

With Additive Manufacturing, No Tooling Is Required

In conventional manufacturing methods, tooling can easily cost hundreds of thousands of dollars. With AM, you print as needed, no jigs, fixtures or tooling required.

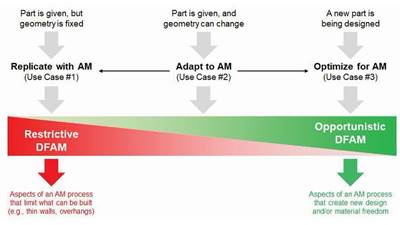

Read MoreAM Enables Manufacturing for Design, Not the Other Way Around

Additive manufacturing allows us to make any shape we want, without having to adapt the design for the manufacturing process.

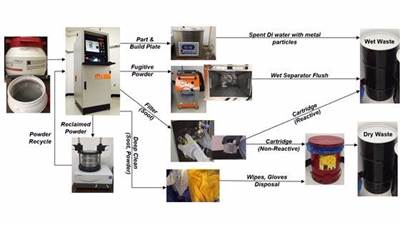

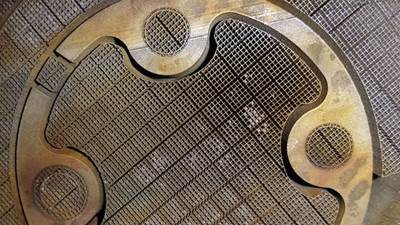

Read MoreSeries: Installing a Metal 3D Printer

A five-part series documents one manufacturer’s experience and lessons learned while installing a powder-bed fusion metal 3D printer.

Read MoreVideo: Where Does Additive Manufacturing Make Sense?

Can 3D printing produce a useful, functional part? The answer is, unequivocally, yes. Editors discuss where and when AM makes sense in this video.

WatchClosing Additive Manufacturing’s Skills Gap

Cincinnati State’s new additive manufacturing certificate program offers a lesson in workforce need versus availability.

Read MoreInstalling a Metal 3D Printer, Part 5: Environmental Regulations

PADT’s fifth and final blog entry about its experience installing a Concept Laser Mlab Cusing R metal 3D printer focuses on environmental regulations and concerns.

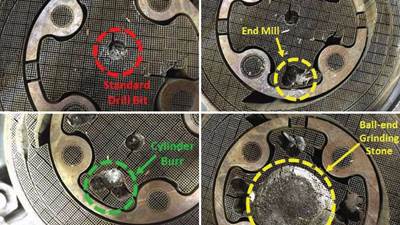

Read MoreRemoving Metal Supports from AM Parts

What is the best way to remove metal support structures from AM parts?

Read MoreInstalling a Metal 3D Printer, Part 4: Prevention and Mitigation

PADT’s fourth blog entry in a five-part series about their experience installing a Concept Laser Mlab Cusing R metal 3D printer tackles safety risks with a focus on prevention.

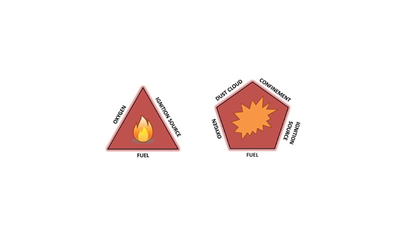

Read MoreInstalling a Metal 3D Printer, Part 3: Safety Risks

PADT’s third blog entry in a five-part series about their experience installing a Concept Laser Mlab Cusing R metal 3D printer tackles safety risks and ways to mitigate them.

Read MoreWill My AM Part Explode?

Will my additive manufactured part explode? Not if you’re careful. Postprocessing parts built from metallic powder requires extra precautions.

Read More