Installing a Metal 3D Printer, Part 5: Environmental Regulations

PADT’s fifth and final blog entry about its experience installing a Concept Laser Mlab Cusing R metal 3D printer focuses on environmental regulations and concerns.

What Waste Streams Originate in Metal 3D Printing?

This is the fourth part of a five-part series discussing things we learned installing a metal 3D printer (specifically, a laser powder bed fusion machine).

Sources of Waste

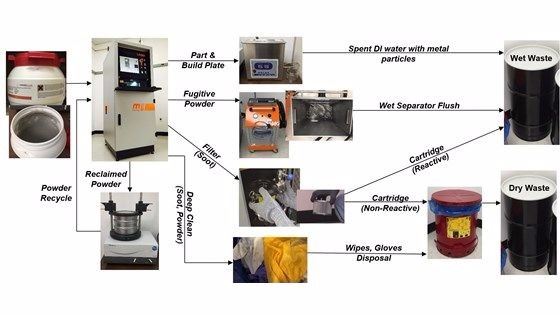

As shown in Figure 1 above, metal powder used in this process ends up in dry and wet waste. The dry waste can be composed of wipes and gloves with powder and soot, and the wet waste is mostly composed of water and suspended metal particles (from the wet separator and ultrasonic cleaner). For reactive alloys, waste can also consist of filter cartridges that need to be suspended in water throughout. Because the wastes contain metal powders, we must stop and ask if this is safe for sending to our landfills and into our sewers where there is a risk of contaminating groundwater and creating other long-term environmental havoc.

Is this Waste Hazardous?

There are two sources for this information: the EPA (in the U.S.) and the powder supplier’s data sheets. It helps to begin by understanding some definitions: (quoted statements are from the EPA, the rest of the text is mine).

- Waste: “A waste is any solid, liquid or contained gaseous material that is discarded by being disposed of, burned or incinerated, or recycled.“

- Hazardous Waste: There are several types of hazardous waste and associated definitions of each. The two main categories are:

- Listed Waste: “Your waste is considered hazardous if it appears on one of four lists published in the Code of Federal Regulations (40 CFR Part 261).” I have looked at this list and to the best of my knowledge, no metal powders of concern to the metal 3D printing process appear on this list (as of July 10, 2017). The metal powders currently used are also not considered acute hazards.

- Characteristic Waste: In addition to listed wastes, the EPA specifies certain characteristics that a waste may possess (even if not listed) that would make it hazardous. In the context of metal powders, the potentially relevant categories are:

- “It catches fire under certain conditions. This is known as an ignitable waste.”

- “It is harmful or fatal when ingested or absorbed, or it leaches toxic chemicals into the soil or ground water when disposed of on land. This is known as a toxic waste.”

Due to the generality of the definitions of “Characteristic Waste,” and the lack of available data in the public domain such as from a TCLP test (toxicity characteristic leaching procedure), it is hard to dismiss these as not being relevant. For each of our waste streams, consider the arguments below:

- Dry Waste: We know that given the right conditions and an ignition source, that these powders, especially reactive alloys and combustion products, can ignite.

- Wet Waste: We also know that while water serves as passivation for powders, we cannot guarantee that the powder will always stay in a wet state if it is not disposed as such. Evaporation, for example, can leave behind combustible powder.

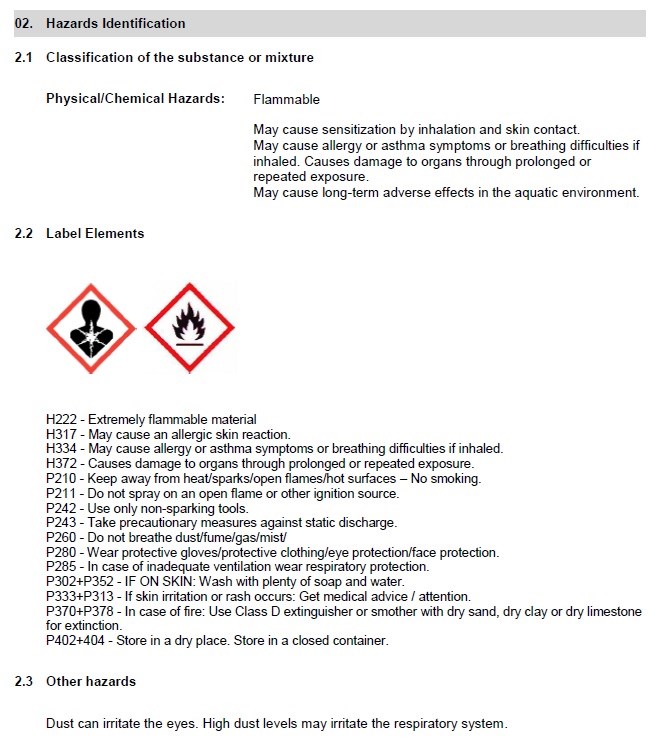

Another source of hazard information is the Safety Data Sheet (SDS) or Material Safety Data Sheet (MSDS). Some metal powders are more hazardous than others, so when planning, consider looking at all the alloys you may possibly be using in the future and ask for SDS sheets on all of them. One example, Ti6Al4V powder, clearly shows significant hazards present (see Figure 2 above).

Waste Regulations

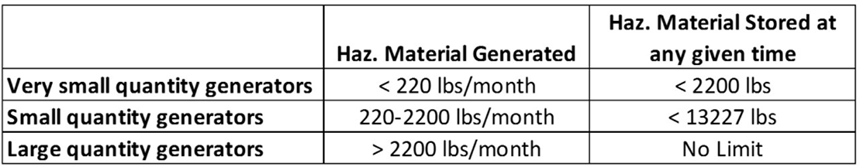

The EPA established three categories of waste generators in their regulations, listed above in Figure 3 along with the relevant quantity of waste generated and stored (visit EPA’s site for the full list, this is not comprehensive). The EPA cites these numbers in hundreds and thousands of kilograms, hence the strange numbers as listed in pounds.

Note that this is the sum total of all hazardous wastes your work is generating (in our case, dry and wet wastes combined), not a limit per category. Depending on what category you fall in, you will need to follow EPA’s regulations. Additionally, some states may have additional regulations, and this is where I only have studied this problem for my home state of Arizona, which is in line with the EPA’s federal guidelines and does not, to the best of my knowledge, impose additional restrictions. For the full list by state, click here. If you are a “Very Small Quantity Generator” (VSQG) as we are at PADT, the regulations are fairly straightforward and involve three items (quoted from the EPA’s site). The requirements are more stringent for larger quantities.

- VSQGs must identify all the hazardous waste generated.

- VSQGs may not accumulate more than 1,000 kilograms of hazardous waste at any time.

- VSQGs must ensure that hazardous waste is delivered to a person or facility who is authorized to manage it.

At PADT, we contract with an industrial waste disposal company that picks up and replaces our waste containers. Yes, this adds cost to the process, and at least one company has developed a method to significantly reduce wet waste (which tends to be the larger of the two) by employing a filtration device. Similar innovations and a general focus on reducing waste can drive these costs down.

Approaching Regulations

As with all regulations, one can approach them by focusing on the specificity of the language. While this is important, it is also useful to seek to understand the intent of the regulation. When it comes to these wastes, I ask if I would be comfortable carrying it in my car and disposing it in my hypothetical backyard landfill (dry waste) or my local water body (wet waste). The answer to both, for me, is NO. So why should I ask my city to do this? This is understandably an exaggerated way of looking at the problem, but I believe that it, at a minimum, serves as a risk-conservative upper-bound that is useful when addressing uncertainty in these matters.

Blog Post Disclaimers

This blog is intended to supplement the supplier training you must receive before using the equipment, and not meant to replace it. In case of conflicting information, your supplier’s training and equipment requirements override any discussion here.

Local, state and federal regulations vary, and are important. Partner with your local environmental authorities when making decisions

My personal experience derives specifically from the use of Laser-based metal 3D printing tools, specifically Concept Laser’s MLab Cusing R equipment. I expect the majority of this information to be of use to users of other laser-based powder-bed fusion metal systems and to a lesser extent to electron beam systems, but have no personal experience to vouch for this.

PADT, the author nor the host of this blog series assume no legal responsibilities for any decisions or actions taken by the readers of this document or of subsequent information generated from it.

About the Author

Dhruv Bhate

Dhruv Bhate is a senior technologist at Phoenix Analysis & Design Technologies (PADT) where he leads R&D efforts in additive manufacturing, with a focus on high performance polymers and metals. Prior to joining PADT, Dhruv spent seven years at Intel developing several laser-based manufacturing processes, taking them from early-stage research to high-volume manufacturing. He also spent a year in the automotive industry, working for India’s largest car manufacturer, Tata Motors.

Dhruv has a Ph.D. in mechanical engineering from Purdue University where he developed constitutive and failure models for the prediction of fatigue fracture in ductile metal alloys. Prior to this, he obtained his M.S. from the University of Colorado at Boulder where he studied the phenomenon of adhesion in Micro-Electro-Mechanical Systems (MEMS) structures.

Dhruv’s passion lies in combining theory, experimental methods and simulation to solve challenging problems in new and effective ways. He has two patents, 16 peer-reviewed publications and more than 30 conference presentations to his name.

Related Content

Video: AM for Harder, Longer-Lasting Brake Discs

Additive manufacturing is being applied to limit automotive brake dust. For a major automaker, Etxetar and Talens are developing a production-speed directed energy deposition system to give brake discs a precise layer of wear-resistant carbide.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MoreVideo: A Mechanical Method for Metal Powder Production

Metal Powder Works has developed a method for producing powders from solid barstock, no melting required. This video covers how the process works and benefits of mechanical production of powders.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreRead Next

Installing a Metal 3D Printer, Part 1: Equipment

When PADT installed a Concept Laser Mlab Cusing R metal 3D printer, the company documented the process from beginning to end. The first in a five-part series.

Read MoreInstalling a Metal 3D Printer, Part 4: Prevention and Mitigation

PADT’s fourth blog entry in a five-part series about their experience installing a Concept Laser Mlab Cusing R metal 3D printer tackles safety risks with a focus on prevention.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More