Installing a Metal 3D Printer, Part 4: Prevention and Mitigation

PADT’s fourth blog entry in a five-part series about their experience installing a Concept Laser Mlab Cusing R metal 3D printer tackles safety risks with a focus on prevention.

How to Minimize Safety Risks in Metal 3D Printing?

This is my fourth post discussing things we learned installing a metal 3D printer (specifically, a laser powder-bed fusion machine). If you haven’t already done so, please read the previous posts using the links below, in particular part 3 which is a prequel to this post. I also recommend reading my post on the difference between reactive and non-reactive alloys in the context of this process.

In the previous post, I identified four main risks associated with operating a laser-based, powder-bed fusion metal 3D printer such as the one we use at PADT, a Concept Laser MLab Cusing R. In this post, I address three of these risks in turn and first discuss how the risk can be prevented from manifesting as a hazard (prevention) and then address how it can be mitigated in case it does result in an incident (mitigation). I will deal with the fourth risk (environmental damage) in the next post. As with the previous post, my intent is to inform someone who is considering getting a metal 3D printer and not be comprehensive in addressing all safety aspects. The full list of disclaimers is at the end of this post.

Fire and Explosion

1. Prevention:

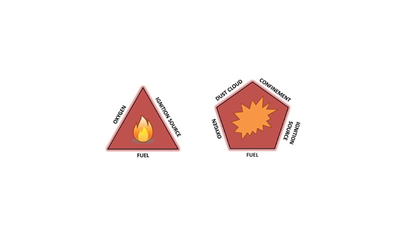

The key to preventing a fire is to remember that it needs three things (“the fire triangle”): fuel (metal powder or soot), an ignition source (laser or spark) and oxygen. While certified equipment is designed to operate in a safe manner when bringing the laser and the metal powder in contact by doing so in an inert gas environment, you, as the operator, are responsible for avoiding any ignition sources when handling powder or soot outside of the inert environment. This is because two of the three aspects have been met: fuel (powder or soot) and oxygen (in the ambient). As long as basic risks are eliminated (sparking equipment, smoking, etc.), the primary risk that remains is electrostatic discharge (ESD) and thus the main piece of preventive equipment is an ESD wrist-strap, as shown in Figure 1, or equivalent ESD management methods.

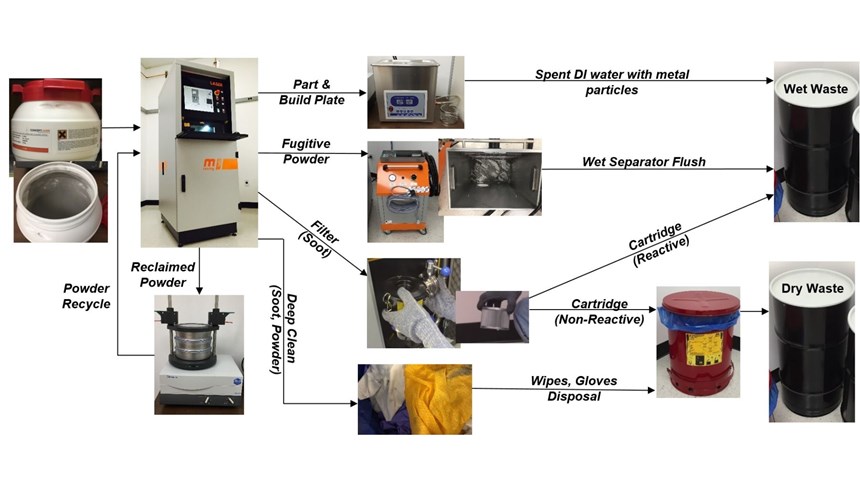

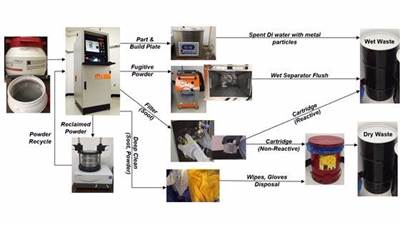

It helps to appreciate the life cycle of the powder, as it goes from purchased jar to ending up returned as recycled powder (the majority of the powder), or in the wet or dry waste streams. This is shown in Figure 2. While this looks quite complex, coming out of the machine, the powder and soot only have four streams that you have to follow: the powder trapped in the part, the powder that you will recycle, the soot and powder trapped in the filter, and what will be cleaned with wipes and accumulate on gloves. While this is not comprehensive (internal hoses and shafts can also accumulate powder), these are the ones operators will deal with on a regular basis.

Mitigation:

In addition to doing everything we can to prevent fire, we also need to be prepared in case it does happen. There are (at least) four aspects that need to be considered or dealt with in turn below:

Personal Protective Equipment (PPE)

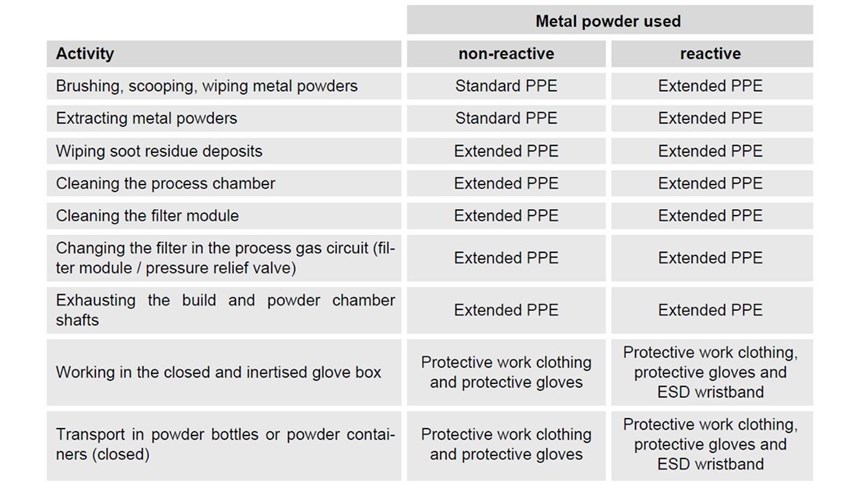

PPE is your self-defense in case of a fire and it is thus a critical element of the safety procedures you need to pay attention to and remember. Tasks are of varying risks, and our supplier recommends PPE for this process in three categories:

- Protective Clothing: A lab-coat that covers your arms, protective gloves, and ESD strap if working with reactive metals

- Standard PPE: Respirator, nitrile gloves, face mask (if not integrated with respirator), ESD strap

- Extended PPE: Standard PPE PLUS

- Fire-rated bunny suit, fire-rated gloves (see Figure 3)

In Table 1 above, you’ll see a list of all activities that involve some risk of ignition (or inhalation, to be discussed in the next section) and the associated level of PPE recommended.

PPE can be tricky to implement consistently since there are several tasks of varying risk levels that require different PPE. The conservative approach is to prepare for the worst case and wear extended PPE at all times. But this can make you uncomfortable for long periods of time, reduce your mobility for some tasks and introduce human error. Instead, here is the three-step logic I use for remembering what to wear:

- Always wear gloves, goggles and protective clothing (lab-coat) when you work with the machine—make this a rule even for the simplest of tasks like using the keyboard and mouse

- If you are directly handling (i.e. not through a glove box) virgin or recycled non-reactive metal alloy powder (i.e. no reactive powders or combustion products), standard PPE is adequate

- For everything else, you need extended PPE

Fire Extinguishing

There are several recommendations for how to manage fire extinguishing. This is an area where you need to get your fire marshal to weigh in. What is clear is that water and CO2 are not safe choices for metal fires [NFPA 484 6.3.3.5(1)]. For extinguishing fires, the consensus is to use Class D fire extinguishers, such as the one shown on the left in Figure 4. The fire extinguisher needs to be a Class D since this is the one rated for metal fires. The main training aspect is to ensure it is pointed down at the base of the fire rather than at it, followed by sweeping.

What to do with water sprinklers? Water can be dangerous for metal fires, but the risk of not having any sprinklers may outweigh the risk of water exacerbating the fire. This is a function of how much risk you are introducing—the amount of powder, proximity to other flammable sources, area surrounding the printer, etc.—and is a decision best made together with your fire marshal.

Powder Storage

Powder storage will involve powder in unopened jars, opened jars, as well as in the overflow collector which is on the machine. It is best to store opened and unopened jars in a flammables cabinet as shown on the right in Figure 4. This is not essential for non-reactive alloys, but necessary for reactive metal alloys. For large quantities of reactive alloys, blast proof walls may be necessary—something your city officials and fire marshal can guide you on. (Do not neglect the importance of getting their buy-in early.) Finally, most cities will require you to fill out paperwork and show on a plan (map) where you are storing your powders, and what their composition is. This is to help inform the fire-fighters that there are metal powders onsite, and where they are located in case of a building fire. If you do plan on working with reactive alloys in particular, you must involve your fire marshal sooner rather than later.

Powder Inhalation & Contact

Prevention:

The main method of minimizing risk of powder inhalation is through the use of a respirator. These come in many forms, but the two most recommended for this process are respirators with built-in face-masks (as shown in Figure 3), and, more preferably, the PAPR respirator, which delivers a positive pressure of air. (Click here for more information). N95 and higher respirator filters are recommended, though N100 are ideal.

Contact with powder is avoided by wearing gloves at all times when handling the machine. It is also useful to minimize risk of carrying powder outside the metal 3D printer area:

- Before starting work, put away watches, wrist jewelry and cell phones.

- Once done with the work, take off your protective coat and wash your hands and arms up to elbows before handling anything else.

- Consider installing an adhesive floor mat for you to step on as you walk out of the room.

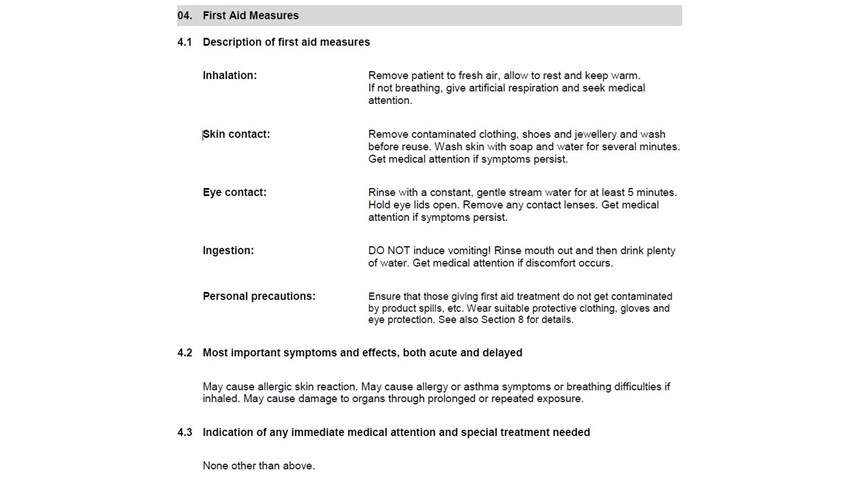

Mitigation:

What to do in case of exposure is typically documented in the SDS (Safety Data Sheets), which is specific to the material in question, as shown in Figure 6 above. Ensure you have an SDS from your powder supplier for all powders you order, and collect them in a folder that is stored close to the entrance for easy retrieval, as shown in Figure 5.

Inert Gas Asphyxiation

Prevention:

Inert gas (nitrogen or argon) is used for every build and is either stored in cylinders (argon) or piped from a generator (nitrogen). Proper, leak-free facilities setup and equipment performance is essential, as is following recommended supplier maintenance on the equipment itself. An inability to drop to required oxygen PPM levels in the build chamber, or large fluctuations in maintaining them, may be associated with a leak and should be addressed with the supplier before proceeding. Users of the equipment must know where the shut-off valves for the gases are, in case they need to turn it off for any reason.

Mitigation:

The main mitigation device is an oxygen sensor such as the one in Figure 7. This is an important sensor to have—especially in confined spaces around any equipment that relies on inert gases, including the 3D printer and furnace. If oxygen levels fall below safe values, an alarm is triggered and immediate evacuation is required.

Blog Post Disclaimers

This is intended to supplement the supplier training you must receive before using the equipment and not meant to replace it – in case of conflicting information, your supplier’s training and equipment requirements override any discussion here. PADT, the author, and Gardner Business Media assume no legal responsibilities for any decisions or actions taken by the readers of this document.

My personal experience derives specifically from the use of Laser-based metal 3D printing tools, specifically Concept Laser’s MLab Cusing R equipment. I expect majority of this information to be of use to users of other laser based powder bed fusion metal systems and to a lesser extent to Electron Beam systems, but have no personal experience to vouch for this.

Local, state and federal regulations vary, and are important – partner with your local fire marshal (or equivalent authority) as a starting point and take them along with you every step of the way. If in the US, familiarize yourself in particular with OSHA’s guidance on dust explosions and NFPA 484, the National Fire Protection Association’s standard for combustible metals.

About the Author

Dhruv Bhate

Dhruv Bhate is a senior technologist at Phoenix Analysis & Design Technologies (PADT) where he leads R&D efforts in additive manufacturing, with a focus on high performance polymers and metals. Prior to joining PADT, Dhruv spent seven years at Intel developing several laser-based manufacturing processes, taking them from early-stage research to high-volume manufacturing. He also spent a year in the automotive industry, working for India’s largest car manufacturer, Tata Motors.

Dhruv has a Ph.D. in mechanical engineering from Purdue University where he developed constitutive and failure models for the prediction of fatigue fracture in ductile metal alloys. Prior to this, he obtained his M.S. from the University of Colorado at Boulder where he studied the phenomenon of adhesion in Micro-Electro-Mechanical Systems (MEMS) structures.

Dhruv’s passion lies in combining theory, experimental methods and simulation to solve challenging problems in new and effective ways. He has two patents, 16 peer-reviewed publications and more than 30 conference presentations to his name.

Related Content

AddUp Receives ASTM Additive Manufacturing Safety Certification

AddUp Inc. announces that it has received the ASTM Additive Manufacturing Safety (AMS) Certification, becoming the first OEM in the AM industry to achieve this significant milestone.

Read MoreChromatic 3D Materials' RX-AM Free of Volatile Isocyanates

RX-AM platform includes software and RX-Flow printers for use in standard and custom configurations.

Read MoreNIOSH Publishes 3D Printing Safety Guide for Nonindustrial Settings

NIOSH has published a 3D printing safety guide for small businesses and other additive manufacturing users such as makerspace users, schools, libraries and small businesses.

Read MoreDesktop Metal’s Production System P-1 Features Optional Reactive Safety Kit

The kit features ATEX-rated components, as well as critical hardware and software updates that enable safe printing of ultrafine powders.

Read MoreRead Next

Installing a Metal 3D Printer, Part 3: Safety Risks

PADT’s third blog entry in a five-part series about their experience installing a Concept Laser Mlab Cusing R metal 3D printer tackles safety risks and ways to mitigate them.

Read MoreInstalling a Metal 3D Printer, Part 5: Environmental Regulations

PADT’s fifth and final blog entry about its experience installing a Concept Laser Mlab Cusing R metal 3D printer focuses on environmental regulations and concerns.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read More