Assembly Consolidation

How Bridge Production Is Bringing New Possibilities: AM Radio #14A

Additive manufacturing makes bridge production a more natural factor in the production strategy overall. This has important implications for product development and even what products are possible.

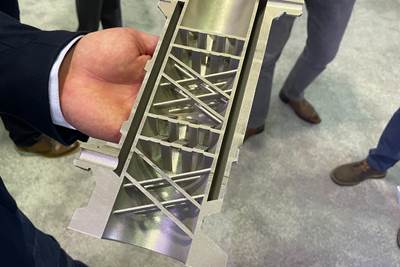

Listen3D Printing for Better Flame From a Gas Turbine Swirler: The Cool Parts Show #42

A Penn State gas turbine researcher turns to additive manufacturing graduate students to help face the challenge of swirler optimization.

WatchVideo: Functional Excavator Features 3D Printed Parts

Oak Ridge National Lab's Project AME swapped an excavator's cab, stick and heat exchanger for 3D printed parts. Stephanie Hendrixson and Peter Zelinski get the scoop.

WatchFor Velo3D CEO, the Future of Metal AM Is Large Producers

The growing demand for metal part production via additive manufacturing will be met by producers that start small and massively scale, says Velo3D’s Benny Buller. Thus, AM will follow a different path from other part-making technologies.

Read MoreUsing Large-Format Additive Manufacturing for Serial Production

First tools, then production parts. This pattern with industrial 3D printing at small and mid sizes has now come to the biggest additive machines as well.

Read MoreCustomizable, Recyclable Shoes with 3D Printed Platform: The Cool Parts Show #37

A 3D printed TPU platform is the key to both comfort and sustainability for these custom heels manufactured on demand.

WatchAdditive Manufacturing for Rail Industry Is Gaining Traction at Neighborhood 91

Locomotive manufacturer Wabtec is the first tenant of Pittsburgh’s N91 additive manufacturing ecosystem, where the company is ramping up production via laser powder bed fusion.

Read MoreThe 12-Month Transformation of a 3D Printed Product's Design

Rapid product development and continuous improvement are among the advantages of utilizing 3D printing for production. Retraction Footwear offers a literal illustration of the design evolution possible in just one year.

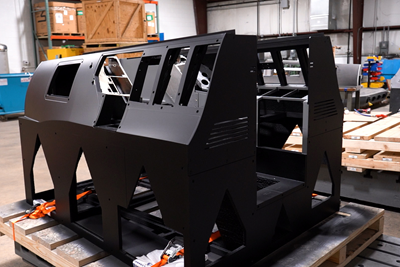

Read MoreFlight Simulator Made Through Large-Scale 3D Printing: The Cool Parts Show #33

Our biggest cool part so far! Printing this massive structure in one piece saves cost and time for L3Harris.

WatchHow Is Additive Manufacturing Sustainable? AM Radio #2B

Additive manufacturing is often closely associated with sustainability, but why? And how can companies use AM to develop sustainable processes? Stephanie Hendrixson and Julia Hider discuss in this episode of AM Radio.

Listen