Pittsburgh's Neighborhood 91 (N91) is perhaps the most ambitious additive manufacturing (AM) campus to be established in the United States. With a name that nods to the city’s famed 90 neighborhoods, the project is part of the planned 195-acre Pittsburgh Airport Innovation Campus. When complete, it will support the entire metal AM ecosystem, from gas supply and recycling through finish machining. Since the announcement of the project in 2019, manufacturers and suppliers across the AM process chain have signed on and committed to locating some part of their operation at the campus, which is adjacent to one of the international airport’s runways.

Strikingly, though, the neighborhood's first tenant to move in favors a different form of transportation. Locomotive manufacturer Wabtec is the very first (and as yet only) company with a physical presence on the campus, occupying 11,000 square feet on one end of its first building. This facility is not the company's first foray into metal 3D printing, but the new space does reflect a decisive pivot toward production with AM. Equipped with a large-format laser powder bed fusion (LPBF) 3D printer, the new site will become Wabtec’s primary location for the development and production of new aluminum locomotive parts made this way.

The Race to Zero Emissions

The rail industry has been slower to adopt additive manufacturing than other markets such as aerospace, yet this industry offers plenty of potential AM applications. Where aerospace tends to prioritize engine components that move fuel, the key components of a locomotive are more likely to be pneumatic in nature — but these provide just as much opportunity for additive to consolidate assemblies with built-in channels that minimize time needed to join parts together.

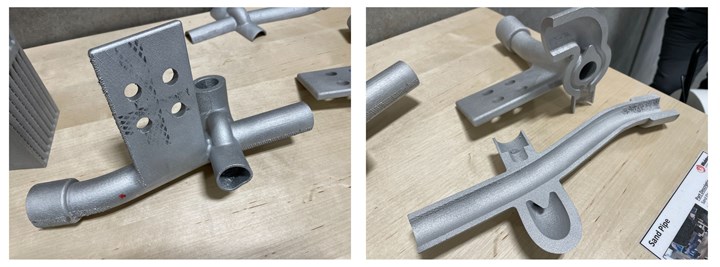

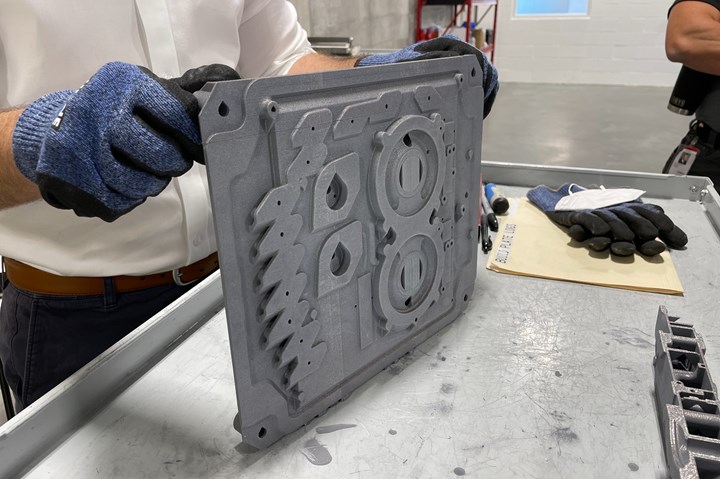

Peter Bocchini, one of the AM leads at Wabtec’s Neighborhood 91 site, shows me one of the brake control panels 3D printed at this facility. The company is finding opportunities for AM in complex components like this that are conventionally assembled from many discrete parts.

"There are 210,000 unique parts in a locomotive," says Charlie Deemer, senior business communications manager (also pictured in the photo above). "Wabtec is assembling them all." In the 1990s it might have taken up to 90 days to assemble a single locomotive, which can range to 76 feet long and weigh 412,000 pounds fully serviced. These days, the assembly time for a locomotive has been reduced — it is now more like 25 days, Deemer says.

The speed is at least in part due to automation and other advances in manufacturing. But assembly time is no longer the top concern for the rail industry. Like aerospace and automotive OEMs, Wabtec and other rail manufacturers are under pressure to meet sustainability goals, reduce emissions and improve fuel economy on older equipment, plus support new hybrid and fully electric locomotives. In the "race to zero emissions," the company believes that additive manufacturing will be key. That is why Wabtec has made the N91 commitment and invested in new 3D printing capacity; replacement parts and upgrades have their place, but new generations of locomotives will benefit from additive parts from the very outset of their journeys.

Wabtec (a conglomerate of three companies — two with 100+ year histories) serves both the freight and transit rail markets, which have different priorities. Weight savings, one of the commonly cited benefits of AM, has little applicability for freight trains, where weight can be an asset rather than a limitation. But commuter trains and other transit applications do benefit from reduced mass, which allows for greater efficiency. The N91 location will mostly serve this latter market.

"Aluminum gives us an opportunity on the transit side," says Anthony Mott, global additive manufacturing leader for the company. The ability to produce complex items quickly from the lightweight material will allow for improved transit vehicle performance as well as simplifying manufacturing and fabrication.

Bringing Production to Neighborhood 91

Wabtec already has additive manufacturing capacity elsewhere. The company operates three different AM locations apart from the Neighborhood 91 site, two focused on polymer and one on metal. A facility in Grove City, Pennsylvania, holds its existing metal 3D printing capacity (both binder jet and powder bed fusion equipment) and would have been the site for increased metal AM production if space had allowed. A low ceiling and limited floorspace at that facility would have constrained any added capacity, so a new site was necessary — and the timing just happened to work out with the N91 project, explains Peter Bocchini, Neighborhood 91 additive manufacturing lead. Now the two locations handle different materials (Grove City deals primarily with nonreactive metals) and have slightly different roles.

"The Grove City site is closer to lab-scale R&D," Mott says, referring to the setup, support equipment and positioning of equipment at that location. While both sites perform production via 3D printing, the N91 facility is being optimized for this work.

The N91 space is dominated by Wabtec’s SLM 800 Hub, a four-laser powder bed fusion system equipped with three exchangeable build boxes and a self-contained powder handling system.

The equipment investment that Wabtec has made reflects this purpose for the N91 site. While the facility is still sparsely stocked and staffed, its centerpiece is an imposing SLM Solutions SLM 800. With four lasers and a build volume of 850 by 250 by 500 mm, this LPBF platform has been engineeered for speed at a large build scale.

The printer is paired with SLM’s Hub, a fully automated handling solution. Wabtec's system is the very first SLM 800 Hub in the United States, and one of only a handful currently in the world. The system incorporates three exchangeable build boxes, a preheating station, automated depowdering, material recovery and permanent filter module. The entire Hub is self-contained to minimize operator contact with the powdered metal and simplify steps like condensate disposal and powder recirculation. While the Hub currently serves just one SLM 800 machine, it could be configured to serve as many as five.

Wabtec’s SLM 800 Hub

The streamlined configuration can operate something like a CNC machine tool with a pallet changer. That is, as each print finishes, the build box is automatically transferred out of the printer to depowdering so that another box can be cycled in. Wabtec has found it is not necessary to heat treat all the aluminum components it prints on this platform, so the postprocessing capacity has been streamlined as well when this step is not needed: A Coscon bandsaw and Haas VF-2 vertical mill round out the site’s equipment lineup.

So far a band saw and vertical mill are the only postprocessing equipment Wabtec needs. Parts are optimized to be as self-supporting as possible during printing and to minimize finish machining.

While each Wabtec AM location can print a variety of types of projects including replacement parts, the company’s goal is to design new products for additive that optimize its benefit. “We need to reset that benchmark,” Mott says. In the case of items that will be produced at this facility, “Additive manufacturing will be the only way to make that part.”

This goal — and resetting the benchmark — accounts for why Neighborhood 91 is so valuable. Bringing all the necessary pieces of the additive manufacturing puzzle together in one place provides advantages for the manufacturers who choose to co-locate here, particularly if their work is ongoing production in metal. Tenants have the use of a shared material warehouse, which allows for the safe storage of powdered metal away from the main production facilities to minimize risk. Gas supplier Arencibia has signed on to join the site, which will make argon easily accessible. And the entire ecosystem is on its own micro power grid, protecting production from outages. Shared resources and the promise of knowledge exchange plus proximity to an international airport and high-, rail- and waterways have helped to attract Wabtec as well as other additive manufacturers.

“Regardless of the current tenants, we needed to expand our operations, so this move was needed for us,” Mott says. “We are excited for continued tenants to come to the site so we can continue to experiencing the benefits that this campus will provide.”

Additive Manufacturing for Locomotives

The types of locomotive parts that Wabtec will produce here are varied, but in general are larger components conventionally assembled from many different pieces, and tend to involve pneumatics. The large-format LPBF system allows for these items to be made in just one piece, and careful design for manufacturing helps to minimize postprocessing. The complexity of the parts also tends to make AM a more economical choice versus conventional methods, Bocchini says. Here are several examples:

Engine Control Chassis

This piece is a control unit chassis for a dual-fuel locomotive (one that runs with both diesel and liquid natural gas). The unit provides cooling to various engine control computer units and previously would have been multiple machined parts brazed together. Large parts like this are one reason Wabtec selected the large-format SLM 800; it is now possible to print each chassis in one piece, speeding the production time and reducing the cost significantly.

Sand Pipe

Because both train wheels and tracks are smooth steel, locomotives need assistance to gain traction. Pipes like this beneath the locomotive spray a blend of air and sand to remove impediments like snow and apply sand to the interface to create friction. The pipes are needed in complex geometries that are difficult to achieve via conventional manufacturing, but simple to 3D print. Assembly consolidation and design changes here helped reduce the weight of these components and improve the flow of media.

Brake Control Panel

Produced for Metroflexx, this large panel is an integrated brake control. Conventionally these control panels consist of 32 separate parts assembled together, but 3D printing can produce a panel in just one piece, reducing the weight from 7 to 2.3 kilograms. Wabtec can print six such panels at a time in the SLM 800 with each build taking about 28 hours. The design has been optimized to avoid support structures except where absolutely necessary (utilizing teardrop hole profiles where possible) and to minimize downstream cost as much as possible. The post-print facing, drilling and tapping can be accomplished in just two setups on a machining center. 3D printing these panels allows for greater customization and changes without the need for retooling as is needed with the conventional manufacturing method.

“Success with these initial parts will spur more and more part families,” Bocchini says. Wabtec expects that additively manufactured parts produced here will be on locomotives next year. Series production for rail ranges from the hundreds to the low thousands, which means that the SLM 800 Hub alone can support full annual production for several part numbers. Even if the current capacity is quickly filled, there is plenty of room to grow in the N91 location.

And there is more growth to come. By the end of the year, Wabtec will have a neighbor. Cumberland Additive, a Texas-based contract manufacturer, has signed on to occupy the other end of the first Neighborhood 91 building; both Mott and Bocchini look forward to the mutual support that will come from being collocated with another metal additive manufacturer. With just one more tenant the current available space will be full — but the neighborhood won’t yet be complete. From the loading dock at the back of the building, the Wabtec crew points out the sites for future development; the rest of the Phase A construction will result in two additional buildings over the next 18 months, with Phases B and C to follow. Wabtec may have been first on the block, but it won’t be alone for long.

Related Content

Video: Construction 3D Printing with Robotics, Geopolymer

Alquist 3D is aiming to revolutionize construction and infrastructure with large-format robotic 3D printing using a carbon-neutral material.

Read MoreNext-Gen Horse Trailers to Be Built With Robotic 3D Printing

Double D Trailers is currently developing a prototype horse trailer that will be made with large-format additive manufacturing. The technology brings potential benefits for labor, weight and design features to this subset of recreational vehicles.

Read MoreMultimodal Powders Bring Uniform Layers, Downstream Benefits for Metal Additive Manufacturing

A blend of particle sizes is the key to Uniformity Labs’ powders for 3D printing. The multimodal materials make greater use of the output from gas atomization while bringing productivity advantages to laser powder bed fusion and, increasingly, binder jetting.

Read MoreConcept Sneaker Boasts One-Piece 3D Printed TPU Construction

The Reebok x Botter Concept Sneaker Engineered by HP premiered at Paris Fashion Week, hinting at manufacturing possibilities for the future of footwear.

Read MoreRead Next

Profilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More

.jpg;width=70;height=70;mode=crop)