The swirler is the component of a gas turbine engine that mixes air and fuel to feed a flame, while introducing turbulence and swirl, and also holding the flame in place. This component performs in so many different ways at once that the design has been difficult to optimize. However, additive manufacturing offers a way to rapidly produce and test different design ideas. In this episode of The Cool Parts Show, we see swirler design iterations made through laser powder bed fusion, and we meet the Penn State University gas turbine researcher who is working with additive manufacturing graduate students to attack the problem of swirler optimization. | This episode of The Cool Parts Show brought to you by Carpenter Additive

The Cool Parts Show is a video series from Additive Manufacturing Media that explores the what, how and why of unusual 3D printed parts. Watch more here.

Have a cool part to share? Email us.

Related Resources

- Bonus episode on the machining and other steps needed for these swirlers

- Penn State Reacting Flow Dynamics Laboratory

- Inside the Penn State AM masters program

- Laser powder bed fusion, an introduction

- The Cool Parts Show #35 — 3D printed turbine blades

- The Cool Parts Show #30 — 3D printed rocket combustion chamber

Transcript

Peter Zelinski

3D printing for power generation.

Stephanie Hendrixson

Additive manufacturing's trial by fire in this episode of The Cool Parts Show.

Stephanie Hendrixson

This episode of The Cool Parts Show is brought to you by Carpenter Additive.

Peter Zelinski

We're at the company's powder production facility in Athens, Alabama.

Stephanie Hendrixson

Specifically, we are standing on top of the Z1, the company's largest vacuum atomizer for producing metal powders.

Peter Zelinski

Want to know how to make metal powder for additive manufacturing? Stick around after the episode.

Peter Zelinski

I'm Pete.

Stephanie Hendrixson

I'm Stephanie.

Peter Zelinski

Welcome to The Cool Parts Show.

Stephanie Hendrixson

This is our show all about cool, unique, interesting, amazing 3D printed parts.

Peter Zelinski

We were recently at Penn State University. We spent some time with a professor there doing some important work and with some students involved in that work with her.

Stephanie Hendrixson

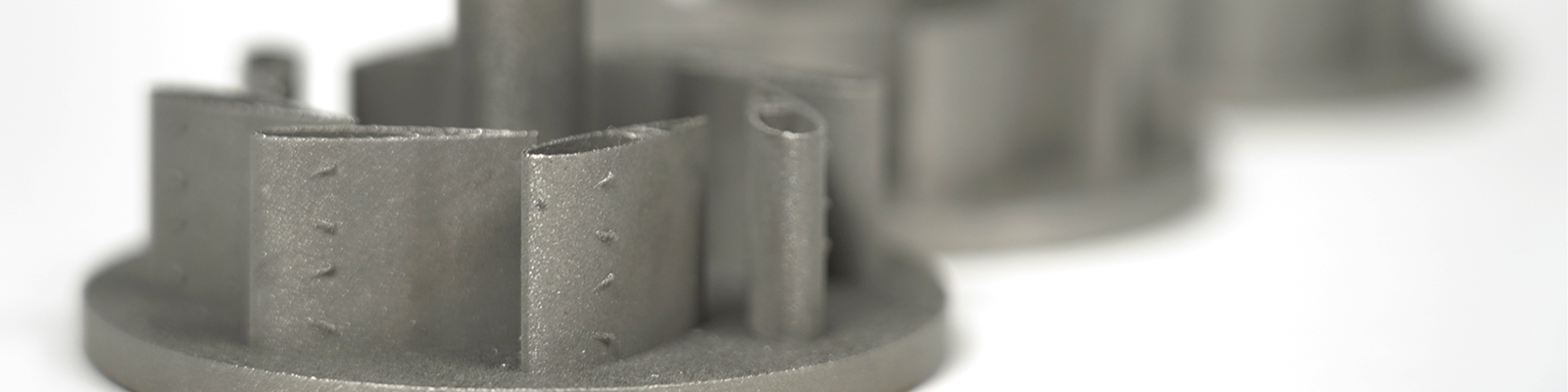

That's right, we had a chance to meet Dr. Jacqueline O'Connor, and to meet some of her undergraduate and graduate students that are working on this problem, how to improve combustion inside the turbine using the design of swirlers, which is what these are.

Peter Zelinski

We learned a lot, we learned a lot including the role of a swirler and how a swirler works. This part maintains and contains the flame inside of a turbine that fuels the turbine. So this is a power generation component and it's doing a lot of stuff all at once. It is introducing turbulence, it is mixing the fuel and the air, it is introducing swirl, it is creating a vortex for the flame, and it is holding that flame in place in part with that vortex. And so this part is doing so many things all at once that it has not really been possible practical to figure out how to optimize the design of this part, get the geometry that maybe can do all of that combination of stuff in the most effective way. To explore little tweaks to the design nuances that could have an important effect, you would need a way to keep on making design after design, and there hasn't been a manufacturing technique that has been easy at iteratively producing design, after design, after design to experiment with it, until now. Enter additive manufacturing.

Stephanie Hendrixson

Alright, so this is Dr. O'Connor's specialty. These are the problems that she has been interested in and has been studying for a long time.

Jacqueline O'Connor

I think one of the things that's most important when it comes to swirler design is that you are trying to co-optimize a whole bunch of stuff at the same time. You're trying to co-optimize your fuel and air mixing, your flame stabilization, but you're also trying to optimize things like emissions performance, right? You don't want to be forming things like nitrogen oxides. And you want to make sure you're burning all the fuel, so you don't get carbon monoxide emissions. You're also trying to optimize for this acoustic problem that is my main area of research. And then there's an entire structure around this, and so you're also trying to optimize for heat transfer and durability. And so I think that's really where additive manufacturing can make a huge impact and is currently making an impact in the field, is it opens up the design space for this one component that's trying to satisfy a huge number of constraints. I think the other thing to keep in mind when it comes to swirler design is that in industry, in industrial applications, they're quite complicated. They have internal flow passages because you're trying to inject fuel. A lot of engines, actually they're called dual-fuel engines, so you have two completely separate fuel circuits, one for liquid fuel and one for gaseous fuel inside. They're really complicated components and they can have dozens of separate pieces that are manufactured and then assembled by hand. And so if you can reduce the complexity of that part, while still meeting all these performance constraints with the use of additive manufacturing, that's a huge benefit from a manufacturing repeatability standpoint and also from an economic standpoint.

Peter Zelinski

Alright, complex geometry, assembly consolidation. I feel like we're swerving into something here.

Stephanie Hendrixson

We are definitely swerving into cool parts territory. There's a lot going on with these swirlers. So on the one hand you have the whole optimization, the co-optimization challenge where you're trying to solve for the best mix of fuel and air, the flame stabilization, the acoustics, all these different things, and 3D printing enabled design is one way that you could solve some of those problems. And then, on the other hand, is swirler is a real manufacturing challenge. You have all these little parts that need to be made, they need to be put together, and 3D printing, as we know, as you said, is great for assembly consolidation, is great for simplifying the manufacturing of a complex component like this.

Peter Zelinski

And in addition to all that, there's an environmental aspect to this too, isn't there? Because if all you were going for is the performance of the turbine, then you would just like jet lots of fuel in there. Or conversely, if you wanted to control emissions, what you would do is starve the flame of fuel use as little as possible. So how do you find a compromise between those two extremes? And the answer is turbulence. Getting just the right turbulence could strike the balance between those two. And it is possible that special geometry realized through additive manufacturing could be the key to delivering that turbulence.

Stephanie Hendrixson

So, fortunately, Dr. O'Connor works at Penn State University, which as you and I know, and have reported on was one of the first universities in the country to offer a master's program in additive manufacturing. They have CIMP-3D The Center for Innovative Materials Processing, which is this cool Applied Research Lab for additive manufacturing. They have Dr. Tim Simpson, who we've worked with on other projects. So there's just a lot of additive manufacturing knowledge, resources, expertise, all in this one place.

Peter Zelinski

Right, right. So Dr. O'Connor is so lucky that she had this problem at Penn State. Students who are part of the additive manufacturing program there got to work on this problem, and these cool parts are the product of their work.

Jacqueline O'Connor

So the project that I gave this graduate course in additive manufacturing design, was to see if they could optimize a swirler design to try to enhance the turbulence in the flow field. A lot of my research right now focuses on the interaction between turbulence and coherent behaviors in flow fields. It's kind of an esoteric topic, but it's actually vitally important for the behavior of flames. Particularly in gas turbine-type technologies. We have a really hard time changing the turbulence intensity in the configuration we have right now, because turbulence, anything you do ahead of the swirler sort of gets washed out in the swirler. We had the idea that, well, if you did something to the swirler itself, maybe you could change the turbulence, that would change the stabilization mechanism and the flame and we could start to understand these things. That was their goal was to generate more turbulence, but I needed certain things to be the same. The swirler had to be the same size because I needed to be able to bolt it into the same experiment. And I needed the same number of blades because there are some certain patterns in the flow that are generated by the blades and I wanted to make sure I wasn't losing those. And then we had some constraints on the open area. I wanted to make sure that we weren't closing things down too much. That would change the pressure drop through the system, it could also dramatically change the acoustics of the system. And we spent a lot of time characterizing the acoustics of the system, so I sort of wanted them to be the same. But in terms of the shape of the blades and the aerodynamics and the things that they did to the blades. It was all them.

Peter Zelinski

The students experimented with a bunch of stuff, including the kinds of variables I think Dr. O'Connor expected them to play with, camber, the airfoil form. But in addition to that, they experimented with some other things. There's a biomimicry aspect of this that I think maybe Dr. O'Connor didn't expect

Stephanie Hendrixson

Biomimicry, right, we are going to get there. But first things first, I think like just as a starting point, this particular swirler has an airfoil design that's pretty similar to what they started with. So I want to bring in the first of the students we're going to hear from. So this is Lach Peeke. He's going to talk about the original airfoil design and then how they started to think about those things about changing the shape and the camber.

Lach Peeke

So the initial swirler design had a very basic, symmetrical airfoil. And so what we wanted to do was increase the lift in the end swirl by changing the airfoil to one that has a higher camber and more lift. And so with that, we picked a much, much more aggressively cambered and thinner looking airfoil. This was chosen to again increase the lift in the end swirl of the fuel and air mixture. So we picked foils based on the NACA system of standardized airfoils that are commonly accepted in aerospace and flight design. Using XFOIL as an open source software we use two dimensional sketches of various airfoils to confirm that the one we chose has the best lift for that aggressive camber.

Peter Zelinski

Aggressive camber, thinner airfoil, is there more going on here?

Stephanie Hendrixson

There definitely is. So if you look closely at all of these swirlers we have here they all have different little variations of these surface features. Some of them also have like this little tail on the end of the airfoil. So let me bring in our next student. So Baily Thomas can talk about what these features are and why they were experimenting with them.

Baily Thomas

So for our design, we first used the original NACA 0015 design or airfoil shape, and we added our surface features to it. The traditional shapes or surface features of the vortex generators and a gurney flap. Vortex generators are on the camber of the airfoil and the gurney flap is at the tail end of it. We selected this because there was a lot of literature associated with vortex generators combined with the gurney flap to be able to increase our lift, which could then help in generating eddies to be able to help the combustion process. So for this, we had to actually scale down using additive manufacturing considerations as well as just the ratios that you find in literature for both the gurney flap as well as the vortex generators to be able to be printed here as you see on this piece. Then we also, using XFOIL an open source software, we changed our NACA airfoil design to a 4415. But we also included the vortex generators and gurney flap as well for this to be able to see how it could assist with the lift of the airfoils. So conventionally speaking, you would have to add the vortex generator to an airplane wing postprocess. You would have to fabricate the vortex generator and then place it on the wing. In this instance, we use additive manufacturing to build the very small vortex generator onto the actual airfoil.

Peter Zelinski

So what Baily referred to as vortex generators, they are actually surface features that are reminiscent of the anatomy of a shark. Here is one more graduate student. Let's hear from her. This is Paula Clares. And she'll talk about that particular aspect of the swirler design.

Paula Clares

What if we were to add additional features on the outside, besides doing the change of modifying, what if we could still enhance even more our design. So we started thinking of what sort of stuff have been out there, either in the industry or in literature. And we ran into this research, this literature research of Cambridge University in which they talk about the hydrodynamics of adding shark fin structures to parts. And this is the way we came, we came across selecting adding the shark fins to the outer part of our airfoil.

Lach Peeke

When we look at 3D printing, that whole unlimited complexity, we wanted to start looking at bio-inspired designs because Mother Nature's had much more time than we have to be perfect engineers. And so sharks are one of those creatures that swim a lot faster than they normally would, and that's due to the hydrodynamic design of the scales that surround the animal. Using the SEM photos of those scales, and previously accepted literature, we're able to use SolidWorks to 3D model individual scales, and apply them to the chord of the airfoil to help increase the lamination of the airflow over the foil.

Peter Zelinski

We haven't even talked about the 3D printing yet. You want to do that real quick.

Stephanie Hendrixson

Yeah, we should do that. How are these made?

Peter Zelinski

Okay, laser powder bed fusion, made through laser powder bed fusion in Inconel. There were actually two different machines involved. One is a more typical sized laser powder bed fusion machine from 3D Systems. Another machine involved in this work is from Xact Metal, which is a startup launched close to Penn State and their specialty is smaller sized, more economical laser powder bed fusion machines.

Stephanie Hendrixson

And we should say as is usually the case, 3D printing wasn't the whole story. There was post-processing, there was machining, there were other steps that had to happen after these were printed as well.

Peter Zelinski

We're gonna do a bonus episode on that. So hang tight for that.

Stephanie Hendrixson

So more to come about the machining and the additional steps. But can we please talk about the flame test?

Peter Zelinski

Let's talk about the flame test. How do we evaluate these?

Stephanie Hendrixson

That's right, so these students are not working on these swirlers as sort of like a hypothetical exercise. There is actually a testbed at Penn State, which we got to see, where these are going to be going through a flame test to see how they perform. So at the same time that the graduate students have been working on swirler design, there's also been a team of undergraduate students who are looking at what's called the blowout limit. So we talked about that whole issue with balancing the flame with the emissions and that's sort of what they're experimenting with.

Jacqueline O'Connor

The undergrad worked with one of my grad students, and they were looking for what's called the blowout limit. There, they were trying to extend the blowout limit. Enhancing the turbulence will certainly help with that, and that's one of the things that we're trying to understand. But what the blowout limit is, is basically, how starved of fuel can you make this flame before the flame lifts up and blows out of the combustor.

Stephanie Hendrixson

So when we return these swirlers, they are going to get prepared, and they're going to go into their flame test. But regardless of what the results of the test are, I think this project has already been pretty successful at demonstrating the value and the potential use for 3D printing in this application, because it allows you to change the geometry to add these features to do all these things without introducing manufacturing complexity.

Peter Zelinski

Yes, so somewhere out there, there is an optimal swirler design, or probably more likely, different optimal designs for different types of turbines and different applications, but an optimal design to get the flame that you need to just sit there and swirl with the minimum amount of fuel necessary. And no one has ever thought to search out that optimal design because of the difficulty involved in getting there. Additive Manufacturing changes that. And now, these parts, the work that Dr. O'Connor and the students are doing, here are the first steps toward that optimization.

Jacqueline O'Connor

These types of issues also show up in things as esoteric as rocket engines and things as commonplace as water heaters. And so the same physics and chemistry and acoustics and fundamental science that we study in the lab can be applied to a huge range of engine technologies.

Peter Zelinski

Alright, I think we've got this.

Stephanie Hendrixson

I think so. You want to start?

Peter Zelinski

Yeah, so this is a swirler. It generates and holds in place the flame that powers a turbine. It creates this vortex of flame that it holds consistent, hopefully with as little fuel as possible.

Stephanie Hendrixson

All of the designs that we have here are the result of work being done by students at Penn State University in an attempt to optimize the turbulence optimize the performance of these swirlers. These different designs show different airfoil shapes, different cambers. They have different surface features like these little shark scales, and the gurney flap on the end in an effort to increase that turbulence. These were all 3D printed using laser powder bed fusion on two different machines. There was some machining and post processing that had to happen as well. When we return these they will be prepared to go into the flame test, and we'll find out how they did.

Peter Zelinski

If you have a cool 3D printed part that you are working on, even if you are still iterating your way toward the best design, tell us about it. CoolParts@AdditiveManufacturing.media.

Stephanie Hendrixson

If you liked the show, leave us a like leave us a comment. Subscribe to the channel so you get notified about new episodes including that bonus episode. And thank you so much for watching.

Peter Zelinski

This episode's brought to you by Carpenter Additive, we are at the company's powder production facility in Athens, Alabama, and we are standing on top of an atomizer. The Z1 is Carpenter Technologies largest vacuum atomizer, and it is the heart of the process for making additive manufacturing metal powder here at Carpenter Additive.

Stephanie Hendrixson

This facility is capable of producing up to 18,000 pounds of metal powder per day. Plant Manager Jordan Ralph talked us through the process.

Jordan Ralph

So an atomizer is a piece of equipment that is capable of melting and pouring molten metal into the stream of high pressure gas that turns that molten metal into tiny tiny droplets that ultimately cool and form our powder, which looks like grey dust. So to start our process, and the ultimate end to end solution that we have here, we bring in raw materials, all the way down to individual elements. So nickel, cobalt, chrome, moly, niobium, we bring all of those raw materials into the shop, we utilize those materials to build charges that go into the atomizer. As you walk that flow path, you run through our charge makeup area where all of the materials are weighed out in very exact quantities, and that ensures that we're able to hit our customer specifications and hold the tight tolerances that we're looking for on a chemistry perspective. From there, the material is flown to the top of the atomizer and charged into the furnace. As the material is produced it's poured out and is collected at the bottom of the atomizer. The material is then taken and transferred into a bolt container for processing through the rest of the value stream. The next stop for any of our as atomized powder would be the screener. So that will remove the coarse portion of the powder. From there, we take it through air classification, that takes the fine portion of the particle size distribution out and makes the final cut for an additive material like a 10 to 45. From there, we stacked up all of those individual lots and put them into the 12,000 pound blender to make the single homogenous blends. At that point, we are able to pack in any configuration that the customer is looking for, whether that be drums, bottles, PowderTrace Hoppers, we've got a lot of options to meet the customer's needs. The optimization capability and all of the powder capabilities gives us a unique position where we're actually able to produce the powder, run testing through additive machines all the way through HIP and heat treat, do final testing on those products and then make additional changes or try to optimize you know things like our chemistry or sizing so that we ultimately can serve our customers better.

Related Content

Freeform: Binder Jetting Does Not Change the Basics of Manufacturing

Rather than adapting production methodologies to additive manufacturing, this Pennsylvania contract manufacturer adapts AM to production methodologies. In general, this starts with conversation.

Read More3D Printed NASA Thrust Chamber Assembly Combines Two Metal Processes: The Cool Parts Show #71

Laser powder bed fusion and directed energy deposition combine for an integrated multimetal rocket propulsion system that will save cost and time for NASA. The Cool Parts Show visits NASA’s Marshall Space Flight Center.

Read MoreTwo 12-Laser AM Machines at Collins Aerospace: Here Is How They Are Being Used

With this additive manufacturing capacity, one room of the Collins Iowa facility performs the work previously requiring a supply chain. Production yield will nearly double, and lead times will be more than 80% shorter.

Read MoreVariable Resistance Valve Trim Achieves Lead Time Reduction Through AM: The Cool Parts Show #69

Baker Hughes is realizing shorter lead times and simplified manufacturing through powder bed fusion to produce valve trims previously assembled from many machined metal parts.

Read MoreRead Next

3D Printed Turbine Blades for More Efficient Power Generation: The Cool Parts Show #35

Blades made through additive manufacturing promise to let turbines run hotter, and therefore generate more power without increasing in size.

Read MoreInside the Penn State Additive Manufacturing Master’s Program, Part 1

PSU's engineering master's degree in additive manufacturing and design offers students and manufacturing professionals a higher education in a continuously maturing field.

Read MorePrototyping Is More Than Printing: The Cool Parts Show Bonus

We hear from students who carried out other steps, beyond the 3D printing, that went into evaluating a complex metal AM component.

Read More