“Bridge production” refers to the initial, lower-quantity production of a new product or part that the manufacturer performs quickly. That is, production carried out now: before the tooling is produced, before the final process is engineered, before the part or product design is even finalized. Additive manufacturing has expanded this possibility, bringing a new level of ease, nimbleness and flexibility to bridge production. This is fundamentally changing what kinds of products and what pace of product development are possible.

On the AM Radio podcast, I got to talk about this with co-host Stephanie Hendrixson. She and I recently encountered examples: Bridge production via AM allows a medical device contractor to bring medical products that otherwise might never have been developed into the field trial state, and it will allow a metal injection molder to bridge the gap into production quantities that MIM cannot cost-effectively address. Listen to our conversation in the episode embedded above, find the episode in your favorite podcast app, or see the transcript below.

Transcript

Peter Zelinski

Bridge production. What are the gaps it’s spanning and where are these bridges taking us? That's coming up on AM Radio.

Stephanie Hendrixson

This episode of The AM Radio podcast is brought to you by PTXPO, the show for North American plastics professionals. Join Additive Manufacturing Media and sister brand Plastics Technology for the first-ever edition of this event in March of 2022. Find more information at PlasticsTechnologyExpo.com.

Peter Zelinski

I'm Pete Zelinski with Additive Manufacturing Media, I am privileged to be joined by Stephanie Hendrixson. Hi, Stephanie.

Stephanie Hendrixson

Hi, Pete.

Peter Zelinski

So here's I want to talk about today, I want to talk about bridge production, because I think we are in danger of under appreciating how important bridge production is.

Stephanie Hendrixson

Okay, that's interesting. I'm game. I feel like bridge production is this thing that I hadn't even heard about a couple of years ago, at least not related to additive manufacturing. And now we're talking about a quite a bit.

Peter Zelinski

Okay, get us started, can you offer a definition of bridge production?

Stephanie Hendrixson

So the way that I think of it is it's either production that happens in between, like prototyping and full scale production. So it's sort of a temporary measure to just get some products out into the world while you're maybe still refining the design, or you're waiting for mold tooling or something like that. Or it's a way of filling like a supply chain gap. Like I think that's where I first encountered the term bridge production was like 2020, people were having difficulty getting parts. And so other manufacturers were 3D printing stuff that would have been injection molded, or or made some other way. So I think I would define it as production that is not full scale, it's probably temporary. But it is real production, and it is making equivalent parts.

Peter Zelinski

Yeah. And bridge production doesn't require additive manufacturing. But 3D printing, industrial 3D printing has has provided a whole lot more option for bridge production than we've ever had before. And I think we're seeing that play out in important ways and realizing new possibilities like in the past, to begin manufacturing required some kind of commitment or investment. And we've talked about the mold moment, like the moment where you have to commit to tooling, you have to invest in it before production can start. Or if it's not tooling, it's some other kind of commitment. It's a lot of programming. It's a lot of setup, and 3D printing, for the most part doesn't have that. So it's not biased toward a particular volume, start producing now at the volume that seems right to produce.

Stephanie Hendrixson

Oh, that sounds right. But you said we are in danger of under appreciating bridge production. What do you mean by that?

Peter Zelinski

Yeah, that's right. So it's sort of creeping up on us. We've had some experiences recently, you and I were we've been in settings where where bridge production was becoming a real thing. And a very important thing. We'll talk about that. But it's it's creeping up on us a little. And as it becomes more prominent and more important and more influential in how we do production, there's a danger of not seeing it happening or under appreciating it happening. And I think there's a couple reasons for that. One is, it kind of looks like prototyping. And and in fact, the prototyping phase of product development could flow pretty naturally into bridge production. One day, you could be doing one and the next day doing the other. It's not the same, because just as you said, it's real production, but it looks a lot like prototyping, or it sort of lands in a similar in a similar sphere. And we've already factored in that 3D printing is a great tool for prototyping. So we don't necessarily see how distinct and how special bridge production is. The other part of it is does it feel like a failure? If 3D printing doesn't do the full full full scale production? You mentioned that bridge productions often temporary? Does ultimate success in production require the highest volume of production? And the answer we're seeing is no being able to do repeatable and use part production at a lower volume through one process. And then higher volume production later through another is an empowerment that dramatically changes the possibilities for what you're manufacturing.

Stephanie Hendrixson

Right. So 3D printing isn't losing. It is a bridge production mechanism that gets you to those higher volumes in a different method.

Peter Zelinski

Yeah, it's it's enabling an opportunity you didn't have before. We've seen some examples of this. We were in Minnesota recently. A company we visited was Resolution Medical, actually we return this our return trip to them, right. Talk about them.

Stephanie Hendrixson

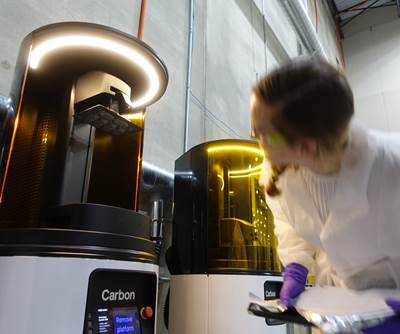

Yeah, so Resolution Medical. As the name suggests, they're a medical device manufacturer. They work with smaller companies. and inventors to get medical devices, things like catheters, surgical tools into the market. And so they've had this experience of doing a lot of that product development, a lot of that prototyping type work, and helping their clients like get things through FDA clearance, that usually involves quite a bit of what we're going to call bridge production. So they're making maybe hundreds or 1000s of some of these devices to get them into clinical trials and things like that. They do injection molding, they do machining, they do some other things. But when we first visited them back in 2018, they had just recently installed their first Carbon 3D printers, they had a couple of carbon M twos, and they were sort of figuring out how to use those devices in that product development work. And and to do this, like bridge production. And it sort of seemed at the time that they were maybe on this trajectory that we've seen other companies take, which is to adopt 3D printing and kind of prove it out with a couple of good use cases. And then just like rapidly scale up, add a lot more machines keep making more and more and more parts. And so when we came back in February of this year, they had six printers and I sort of expected maybe that would be the story. And actually, those printers are not, so that they can make many more of the same part numbers, the printers are there. And there are more printers because they want to make more different part numbers, like they're just doing that much prototyping work, that much product development work that much bridge production, that it makes sense to scale up the capacity. But they're not trying to make millions, they're going to make hundreds 1000s, maybe 10s of 1000s of parts. And then these devices can go on to be made some other way. And like that's a success, even if the production work moves away from 3D printing.

Peter Zelinski

So that's right, yeah, we were first there in 2018, they were doing development work on a lot of medical devices back when we first saw them. And I thought one or more of those would have taken off, and we would see full scale production through 3D printing. That's not what they're doing. And upon reflection, that would have been boring, if that's what they're doing. And these new products they're developing, there's some confidentiality around them. So I'll be a little vague, but we saw this product they're developing, and it relates to heart implants. It's a device related to that. And it was an assembly of 40 different components, all of which they were making through 3D printing, and, and apt to begin going into bridge production on 3D printing, they have the capacity for that we're getting ready to do that. And the lead time for mold tooling, they said even if they can get it fast, it's like four to 12 weeks per mold. And every time often when you and I say numbers like that about the lead time for mold tooling, like we get pushback from that, like, oh, we can deliver holds like much faster than that. And it's true. On a in a sprint, you absolutely can. But in the normal practice of getting tooling, particularly if you have to get tooling, mold tooling for 40 different parts. Yeah, Resolution Medical tells us up to 12 weeks is what they might be facing. So why is the bridge production so powerful in that scenario, it's because quite possibly, there would be no reasonable path to invent and test and certify this product and bring it to market in the absence of that. Or it would take way, way, WAY longer. Or you'd have to go to market with a version of this product that didn't do all you wanted, didn't work as well as you wanted to to because you're sort of you're sort of stuck with the design you locked into when you committed to the tooling.

Stephanie Hendrixson

Yeah. And so like you mentioned, this heart surgery device. And I've been working on writing the story from from this visit. And there was this great quote from Drew Richardson, who is the director of component design. And he said about that project, like 20 years ago, this would have been a five-year project. Now it's a 15-month project, like not just getting to a design that works and getting to parts that work. But actually being able to refine and iterate a little bit on that timeline is pretty powerful. Yeah, so

Peter Zelinski

I walked in, at the very first moment kind of expecting to see full volume production. And if that had been the case, that would have been an under utilization of that 3D printing capacity that they have and under utilization because we have equipment that can do volume production. injection molding machines can do volume production, they can do it very well. The 3D printers at Resolution Medical, those Carbon machines, that capacity is all about doing a type of manufacturing and enabling a kind of time reduction in the development of sophisticated products that no other production capacity can realize.

Stephanie Hendrixson

So it's kind of interesting that you brought up this trip to Minneapolis because we visited quite a few places while we were there. But I had kind of a similar experience at a different manufacturer Smith Metal Products which you have been writing about and I I think that they are looking at binder jetting, binder jet 3D printing in a similar way that resolution is looking at these Carbon printers. Do you want to talk about that?

Peter Zelinski

Yeah, just like you said, with Resolution, that's an article I'm working on Smith Metal Products coming to AdditiveManufacturing.Media. Soon, we'll post it there, but they're all about metal injection molding. And binder jetting and metal injection molding go together really well, they both use powder metal, they both draw on similar metallurgy expertise. They both use sintering. And if you're doing metal injection molding, you've already got all this sintering furnace capacity that that can be put to use for binder jetting, too. But this is a company that wanted to take care with what changes it makes and what capacity it invests in. They were watching metal 3D printing for quite a long time. And yeah, it's these, it's these lower quantity production demands that they were facing, specifically bridge production that finally made them realize this is a capacity they needed to develop as a direct complement to metal injection molding, again, metal injection molding, it's got a mold in it, it's right there in the name. And so that that puts a floor on the volumes that make sense. And Smith Metal, they're good at working with their customers. And they kind of stretched downward a little sometimes in terms of what minimum volumes, they're able to cost effectively accommodate in metal injection molding. But still, there's plenty of demand for MIM like parts, but that are in quantities of hundreds or even thousands don't necessarily make sense for molding. And so they're just getting started with this. But that is going to be their bridge to the way forward new capacity that fills in these other volume levels. Specifically, yeah, the production, that's where the the idea is still in development, they want to start serving the market, but maybe they're not ready to commit to the mold.

Stephanie Hendrixson

Yeah, so something you said earlier was how bridge production can look a lot like prototyping. And I think that was sort of the case at Smith Metal, like we saw a lot of parts that were that were prototypes, like as they in the client, we're kind of just working out what the design should be what this product should be. But one of the big advantages of binder dead is that like they're using the same materials and in most cases that they would also be using for MIM. So it's a really direct line from prototype into small-scale bridge production, and then eventually maybe into metal injection molding, without a whole lot of change in between those steps.

Peter Zelinski

Yeah, that's a really good point, binder jetting to MIM parts, the material properties, that bridge is particularly solid, they're one goes right to the other.

Stephanie Hendrixson

So I think I am, at least personally no longer in danger of under-appreciating bridge production. We've talked about a lot of different ways that additive can complement conventional methods can fill gaps with conventional manufacturing. And it's also bringing these new opportunities when it is being used for product development straight into bridge production, allowing you to work through some design possibilities, maybe before you invest in that tooling.

Peter Zelinski

Additive manufacturing still needs all of the conventional manufacturing processes that we've relied on for a long time. And, and as additive advances. That's the the big theme we keep encountering is that additive is not replacing conventional manufacturing, you know, accepted some places here and there. But but it's more, it just opens the circle is so much bigger and realizes possibilities that weren't achievable before. Like that's what we saw at Resolution Medical, it's a type of production, realizing a promise that we couldn't make before.

Stephanie Hendrixson

Okay, so additive manufacturing has some real practicality for bridge production for filling these gaps bridging these gaps. But all that being said, I do think that there are still scenarios where additive manufacturing can win the scale production and it should win the production. Can we talk about that?

Peter Zelinski

Yeah, you're sort of saying yeah, sometimes the bridge needs to go all the way and become the highway. Let's talk about that. After this.

Stephanie Hendrixson

This episode of The AM Radio podcast is brought to you by PTXPO, a new event for professionals in the plastics industry, designed for the entire North American plastics market. This tradeshow will feature equipment, machinery, materials and technology solutions throughout pavilion exhibit halls. Check out the exhibits attend educational sessions with manufacturing experts and make new connections in the industry. If your business is involved in plastics processing, moldmaking or additive manufacturing, this is the event for you join Additive Manufacturing and sister brands Plastics Technology and Moldmaking Technology for the first ever PTXPO. The inaugural event takes place March 29 through 31st, 2022, at the Donald E. Stephens Convention Center in Rosemont, Illinois. Find more information about attending exhibiting or sponsoring this event at PlasticsTechnologyExpo.com.

Peter Zelinski

Welcome back, Stephanie Hendrixson. and I were talking about bridge production about an entirely different mode of possibility in production that additive manufacturing is realizing, because of its freedom to get started quickly and early at lower production quantities before the full-scale production comes, if it ever does, before we went to break, Stephanie raised the point that sometimes additive can and should go all the way do all of the full scale production. There are instances where that's the right choice where I think we're seeing those instances grow kind of cases where the manufacturer like drinks the Kool Aid and goes all additive. And that that phrase comes right to mind because there was at one of our additive manufacturing conferences in a past year, we were sort of talking about this point with a bunch of panelists on stage and, and Adam Clark from tangible solutions in Dayton, he he said that phrase, he said, Hey, we, we have drunk the Kool Aid, we are we are all additive and doing all of our production that way. So Stephanie, you raised that point instances where additive ought to go all the way talk about that?

Stephanie Hendrixson

Yeah, so I think there are a handful of really good reasons that you might want to look at additive as the full-scale production method, and not ever shift to a different production process. So the first would be because of geometry, like there's something about the design of what you want to make, that cannot be made any other way. So tangible solutions, they would be an example, they make spine implants, and they do some really complicated geometries that would would be difficult or impossible to make through more conventional technologies. Another would be like the GE fuel nozzle, it's overplayed. But this is a case where they took 20 different pieces that used to have to be manufactured individually, and then assembled together, and they condensed it down into one thing that can be printed as one piece. And like there is no reason for GE to ever go backwards on that and go back to the conventional way of producing this nozzle, like the additive benefits are just too great. And we've had a lot of other recent examples of complicated, interesting geometries that could not be made efficiently or could not be made at all any other way. Our colleague, Julia Hider, just posted a story recently about these foam pieces that go into a Wilson baseball mitt. And this is an instance where they're not just replacing the foam material, but they're adding additional functionality. They're making the foam more flexible or more stiff in different areas. And so they're introducing something that wasn't there before. And those are the instances I think where design is the reason that you go to 3D printing and you stay with 3D printing.

Peter Zelinski

Let me tell you about a trend I see in that those those examples you just gave of instances where the geometric complexity is so great that it argues for additive as the production method, as the speed and cost effectiveness of 3D printing increases the value that the complexity of the geometry has to deliver goes down. So at the start of this, we saw, yeah, this fuel nozzle inside this aircraft engine, that formerly was this combination of 20 or so different, really sophisticated welds and bracing that had to make this assembly, that complex additive part delivered all that value and all that value was justification enough to stick with 3D printing, skip into the future. There are more productive additive processes. And we're looking at some complicated components for baseball mitts now justify 3D printing, like it's becoming that much more accessible.

Stephanie Hendrixson

Yeah, absolutely true. So that's one reason that 3D printing could win for production. Another reason which we've talked about a lot is customization. Like if you're trying to make something that's specifically for an individual, like the turnaround time just wouldn't be possible in some of these cases. So I'm thinking examples like Fitz Frames where you scan your face with an app and they make glasses frames that are precisely sized to your face and the fit your ears just right Aetrex insoles so we did a cool part Show episode about this company. And they can 3D print insoles, kind of similar to the baseball mitt example that they have this lattice and the lattice adjusts based on the way that they you stand in the way that your feet meet the ground. We've seen actually quite a few footwear examples. We've also seen things like orthotics, prosthetics, devices that are made custom to patient whether they are human or animal. And so like there are a lot of cases where like if you're only trying to make one of each unique part, it doesn't make sense to try and do molding or to do some other process boy similar

Peter Zelinski

to what we were saying with bridge production and production that realizes a brand-new possibility. That's what this is to tailor the product to the individual user, human or animal, as you say, because we've seen some some veterinary surgery examples. But sometimes it's it's one part, you'll make one time and implant for a special need. But sometimes it's a thing that is utterly mass-produced at large quantities, it's just that every single piece within that quantity is a little different, because it's got a little different customer for it. And yeah, we're, we're, you've got locked in hard. unvarying mold tooling, or any kind of tooling, you have to produce the same thing time after time after time. And that's how we think of what production is. But now, 3D printing is delivering this new mode where every piece a little bit different, that can be what production is, too. So we've got two of them. Here, we've got sort of niches where geometry makes sense. And those niches are getting more numerous and growing. And then personalization and or customization examples.

Stephanie Hendrixson

And I'll put one little caveat on the the customization I said, where it doesn't make sense to go into molding with some of these products. But maybe it does, if the mold itself is 3D printed. So there's been some examples of that Smile Direct Club is a user of HP Multi Jet Fusion machines, and they make dental aligners and they're using those printers to build the tooling that allows them to mold those aligners and so like each mold is individual is is unique, because each of those aligners needs to be unique. And they found that 3D printing is the right way to build the tooling. Alright, where else

Peter Zelinski

can we go with this, because we're seeing a lot more cases where 3D printing is doing the production and, and a conventional process isn't in sight. And I don't feel like we've categorized all of them yet,

Stephanie Hendrixson

right. So additive manufacturing wins out sometimes because of the equipment investment, it's pretty expensive to buy a mold and to get injection molding services. And so like 3D printing might be the thing that makes economic sense, especially if you're talking about a plastic part. We've seen some examples of this, like on the last episode of the podcast, you and Julia talked about the company that she visited Maxwell June, and they're producing a consumer product, they're selling it, and it's being made on like desktop 3D printers that cost a couple hundred or a couple thousand dollars. Like that is a much more affordable way to go into production in some cases. And so I think that just the like the startup cost for manufacturing is a barrier to entry. And 3D printing is sometimes a way around that.

Peter Zelinski

Particularly if you're serving a customer base where you know, the units you're going to produce are going to be small, and a lot of inventors and that was the topic of our last podcast, a lot of inventors land in that category. So it's not mass market. It's not individual customization, like we were describing before, but it slams sort of in between it is a product with a very specialized customer in mind.

Stephanie Hendrixson

And so that leads me to the last scenario that I want to talk about today, 3D printing might be the serial production method, because the volumes never reach a point that conventional method makes sense. One of the examples you gave last time was the Periscope case, it's a specialized phone case, not something that they're going to sell in huge quantities and like phones change all the time. So to make a phone case that specialized to each new model, a phone that comes out, you may not end up producing very many of any one of those. Another example, there's a company in the UK that I wrote about a couple years ago called Pengraff, and it's a husband-and-wife team. And they make specialized mounting brackets for things like your router, electronics that are eventually going to get outdated and go out of use. And so to mass produce brackets and things to hold these these items doesn't really make sense. But to make them as there is demand for particular devices does make sense through 3D printing.

Peter Zelinski

Okay, so surveying all that from kind of kind of a high-level view, where additive manufacturing is being used for production for the full scale production of the entire run of the product. Someone might ask the question about additive manufacturing adoption, like what industries are embracing this, and that's the wrong way to look at it, because every industry is embracing this, but where it's finding its successes are in these different niches and categories. And there are some big important ones I've heard you identify here. So it's production of components where there's geometric complexity, often because that geometric complexity, either it lets you get exactly the springiness, you want with a solid plastic part, or it gets you the assembly consolidation you want because you're one complex thing replaces what used to be a lot of little stuff put together. So there's the geometric complexity. That's one where else is additive doing production. It's in customization, where the end product is somehow individually tailored to the anatomy or the tastes of the end user. And sort of related to that it's niches. It's not quite as specific as personalization, but it's a product that finds a market Maybe is kind of limited, but additive manufacturing provides an economical way to get there.

Stephanie Hendrixson

I just add to that, like, this is something I've been thinking about recently, because one of the questions that you and I get a lot is like, what is a reasonable quantity to expect that 3D printing can do right? Is it 10,000? Is it 100,000? Is it 2 million? And I think that's maybe the wrong question. Like, 3D printing creates these opportunities for more niches to emerge. So maybe it's not the case that 3D printing is going to produce 2 million shoe soles that are size eight, maybe it's the case that it's going to produce 100,000 of that particular size, and then another 100,000 of like, size 8.25? Or like, do we just get more diversity rather than greater quantities of the thing that already exists?

Peter Zelinski

Right, right. Okay. So that that's really well said, and I think it connects to something that I think is maybe a point to go out on because, okay, this question What quantity is right for additive manufacturing? A lot of variables fit into that, what process are you using, what is the size of the part, certain processes allow nesting of parts within three dimensions, so a little component within a process like that you could potentially make a whole lot of them, I think of an example you wrote about recently Aerosport additive is making some smaller 3D printed components with through Multi Jet Fusion. And they're, they're able to make a bunch of them like we did this cover photo of buckets of production. And he's he's on the cover holding this big container of these 3D printed parts, he made the possibilities for what looks like conventional, traditional full-scale, high-volume production, like they're growing with additive. And that brings us to one more scenario in which additive might be called on to do the full-scale production. We talked about geometry, we talked about niches. Another one I want to, I want to bring up domestic production. And you hinted at this very early on, when we were defining bridge production, you said, sometimes it's a way to start producing locally producing nearby. In the years to come, I think we're going to see more and more manufacturers thinking about their production that way with with a desire and sensitivity to wanting to keep production close, just because of the vulnerabilities we've seen from from supply chains that stretch. And so production without tooling through 3D printing is potentially in some cases, one way to get you there. And so we will see more and more manufacturers making the calculation of what volume can I stretch down to and it's still be viable production that I can keep clothes in complement with, what production volume can I stretch up to, and it still be viable on the 3D printing platform that I'm relying on? And we're going to see that analysis result in incrementally higher and higher and higher quantities being realized through 3D printing. So yeah, domestic production. I'm not going to add that another category where your bridge goes all the way.

Stephanie Hendrixson

Alright, I think we'll leave our conversation there for today. Thank you so much for listening. If you enjoy the show, please make sure to subscribe wherever you get your podcasts. If you'd like to learn more about additive manufacturing, read some of the stories that we mentioned. You can find them all at AdditiveManufacturing.Media Thanks for listening.

Related Content

How Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

Read MoreDMG MORI: Build Plate “Pucks” Cut Postprocessing Time by 80%

For spinal implants and other small 3D printed parts made through laser powder bed fusion, separate clampable units resting within the build plate provide for easy transfer to a CNC lathe.

Read MoreThis Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

Read More3D Printed Titanium Replaces Aluminum for Unmanned Aircraft Wing Splice: The Cool Parts Show #72

Rapid Plasma Deposition produces the near-net-shape preform for a newly designed wing splice for remotely piloted aircraft from General Atomics. The Cool Parts Show visits Norsk Titanium, where this part is made.

Read MoreRead Next

Why Inventors and Additive Manufacturing Go Together: AM Radio #13

The ease of beginning to produce at small scales using 3D printing opens the way to a new class of manufacturer: the inventor making their own product.

Read MoreInjection Mold or 3D Print? How Resolution Medical Pivots Production

Minnesota manufacturer Resolution Medical is finding opportunities for additive manufacturing via Carbon 3D printers as an alternative to injection molding for production.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More