Lithoz GmbH

Mollardgasse 85a/2/64-69

Wien, 1060 AT

43 1 9346612 200

office@lithoz.com

lithoz.com

IS THIS YOUR COMPANY?

As Seen On Additive Manufacturing

Editorial, News, and Products

-

8 Cool Parts From Formnext 2024: The Cool Parts Show #78

End-use parts found at Formnext this year address various aspects of additive's advance, notably AM winning on cost against established processes.

-

Semiconductors, Tungsten, AM Affordability and More from Formnext 2024: AM Radio #56

The trade show included increased applications for the semiconductor market, machine launches and technology advances aimed at cost cutting, plenty of LFAM and more. Listen to our conversation on Formnext 2024.

-

Lithoz CeraFab System S320 LCM Printer Designed for Efficient, High-Capacity Industrial Serial Production

Formnext 2024: The system offers a build speed of up to 150 layers per hour and layer thickness of 20–200 µm.

-

Lithoz Establishes Japanese Technology Network for 3D-Printed High-Performance Ceramics

As One, Mitsui Kinzoku and Yugyōkuen Ceramics have chosen Lithoz as a technology provider in driving growth and advancement in the Japanese additive manufacturing community.

-

Lithoz, ORNL Partner to Advance Processing for High-Temperature Ceramics

The new process could enable laser slurry drying of non-oxide ceramics with high refractive indexes

-

Lithoz Invests in AMAREA 3D Printing Technology Which Combines Up to Six Different Materials in a Single Print Run

The company is looking to actively support a new dimension of 3D printed, functionally graded components.

-

What We Found at Formnext 2023

New metal processes, new possibilities for existing processes, the next step for copper and more. Here is a summary drawing on all our reporting from November’s event.

-

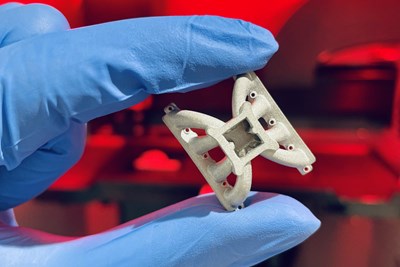

Lithoz’s CeraFab Multi 2M30 Creates Multimaterial, Multifunctional Parts

Formnext 2023: The CeraFab Multi 2M30 is a lithography-based ceramic manufacturing 3D printer that can produce highly complex multimaterial structures by combining several materials — not only in varying layers of printed components but also within a single layer.

-

Lithoz, Himed Partner for Research on 3D-Printable Medical-Grade Bioceramics

This collaboration is designed to help grow the range of biocompatible materials suitable for a future that includes highly customized, patient-specific medical solutions that can be printed on demand.

-

Incus Successfully Tests Lithography-Based Metal Manufacturing for Lunar Environment

The project aim was to develop a sustainable process that uses lunar resources and recycled scrap metals (eventually contaminated by lunar dust) to produce spare parts on-site which could help and enhance human settlement on the moon.

-

Lithoz Partners With SiNAPTIC for Ceramic Additive Manufacturing

The deal includes joint sales and marketing activities, as well as the purchase of seven Lithoz CeraFab S65 Medical printers for SiNAPTIC’s new research center in Lafayette, Colorado.

-

Lithoz Supports Zenit Smart Polycrystals’ Materials for Solid-State Lasers

The collaboration includes alignment of Lithoz’s lithography-based Ceramic Manufacturing (LCM) technology for the Zenit process, as well as support for market, organization and innovation strategies.

-

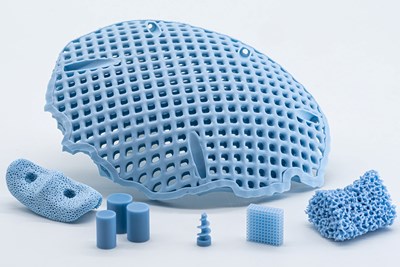

Lithoz Offers Improved Ceramic Material for 3D-Printed Bone Replacements

The company says the 3D printed, patient-specific parts made of hydroxyapatite are well suited for bone replacements in the medical and dental field.

-

10 Important Developments in Additive Manufacturing Seen at Formnext 2022 (Includes Video)

The leading trade show dedicated to the advance of industrial 3D printing returned to the scale and energy not seen since before the pandemic. More ceramics, fewer supports structures and finding opportunities in wavelengths — these are just some of the AM advances notable at the show this year.

-

Lithoz CeraFab S65 for Precise Ceramic 3D Mass Production

Formnext 2022: Lithoz CeraFab S65 ceramic 3D printers have database-supported storage and management of all process data, enabling seamless documentation of print jobs.

-

Lithoz Acquires CerAMing

With the acquisition of CerAMing and its LSD printing technology, Lithoz says it now fully covers all strategically relevant market potentials in ceramic 3D printing.

-

3D Printing Brings New Possibilities for Manufacturing With Ceramics: AM Radio #27A

AM expands the opportunities for ceramics. On the AM Radio podcast, a discussion of various 3D printing processes making use of ceramic material, and various new applications for ceramics that are developing as a result.

-

Lithoz CeraMax 3D Printer for Large Ceramic Parts

Using laser-induced slipcasting (LIS) technology, the CeraMax Vario V900 3D printer is said to produce large ceramic parts in full densities.

-

10 Trends from Formnext 2021

The largest trade show for additive manufacturing technology returned with an in-person format this November. Editors Peter Zelinski and Stephanie Hendrixson share sights and trends from the event.

-

Incus Project to Test 3D Printing Spare Parts in Space

Project goal is to assess the feasibility of processing scrap metals available on the moon’s surface to produce a high-quality final product via a zero-waste process.

-

Lithoz Launches Entry-Level Ceramic 3D Printer

The CeraFab Lab L30 was developed for those new to ceramic 3D printing and is well suited for shop floors, research purposes and small-series production.

-

3D Printed Ceramics Serve As Both Bone Graft and Support

Bioceramics including tricalcium phosphate and zirconia have been used to replace and stabilize human bone in reconstructive surgeries. Now, 3D printing brings customization and new design opportunities to these medical devices.

-

Bioceramics for Bone Replacement: The Cool Parts Show #18

A mandibular cage made up of two different bioresorbable ceramics points to the future of bone graft and reconstructive surgeries in this episode of The Cool Parts Show.

-

What Is Vat Photopolymerization?

Vat photopolymerization was the first AM process to be successfully commercialized. Three decades later, this technology has shown how AM is capable of scaling to volume production and making custom products on demand.