The most recent Formnext show, held late last year in Frankfurt, Germany, felt like an important installment of this event.

To be sure, every installment is important. The expo held every November in Frankfurt is the world’s leading additive manufacturing trade show, and participation in it continues to climb. The recent show’s 859 exhibitors represent a 7% increase from the preceding year and the 33,000 attendees were up 11% from the previous year. But perhaps even more notably, technology seen at this show continues to advance through major steps, not just small increments, even this far along in AM’s application to industrial production. At the recent Formnext 2023, I saw various prominent developments that seem likely to play a major long-term role, and seem likely as well to expand our sense of how AM works and what

Formnext this year drew 33,000 attendees, up 11% from last year. The largest annual event in additive manufacturing is held every November in Frankfurt, Germany.

this mode of manufacturing is able to do.

Two writers from our staff covered the event: Executive Editor Stephanie Hendrixson and I both traveled to Germany, and our coverage of the show took many forms. You can hear our extended-length conversation about the show in an episode of the AM Radio podcast; find reports on many of the technology advances we found in our Formnext 2023 video playlist; and learn about end-use applications we discovered in an episode of The Cool Parts Show highlighting “8 Cool Parts from Formnext 2023.” What follows is an overview that draws on all these resources. Here is just some of what struck us at Formnext late last year:

Cold Metal Fusion

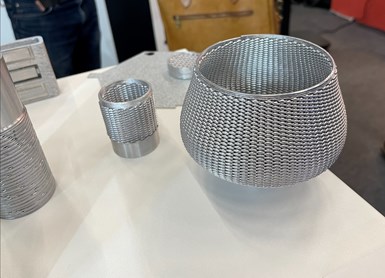

Cold Metal Fusion was discussed at Formnext last year, but applications of the capability were on display throughout the show this year. The new metal AM process uses SLS as a means of fusing metal powder into a pre-sintered part. This collection of Cold Metal Fusion parts was on display in Nexa3D’s booth. At the very back is a lathe toolholder we discussed in more detail on The Cool Parts Show.

The sinter-based metal AM technology developed and advanced by Headmade Materials in collaboration with various other producers was present at the last Formnext just over a year ago, but the show this year seemed to mark the arrival of this new process. Metal parts made via Cold Metal Fusion were prominent in various companies’ exhibits.

Cold Metal Fusion is a metal 3D printing process that uses the polymer process selective laser sintering (SLS) as its platform. In a segment from our Formnext episode of The Cool Parts Show discussing a lathe toolholder now manufactured this way (by MIMPlus applying SLS capability from Nexa3D), I offer this description of Cold Metal Fusion:

“[Via SLS], polymer is melted as a way of fusing metal powder, fusing it into a pre-sintered green form that goes on to an additional sintering step where it realizes its full density, strength and hardness. The process is like binder jetting, but a difference with Cold Metal Fusion is that the polymer and metal are pre-mixed to a uniform consistency all throughout. The result, it is said, is the possibility for pre-sintered parts that are bigger and stronger, more resilient for rough handling during an industrial process and even for machining in the green state ahead of sintering.”

One appreciable side effect of the arrival of this process is that there is now, clearly, an array of sinter-based approaches to metal 3D printing. This has been true for years, but binder jetting still has dominated the thinking as to how a metal part might be produced when sintering is permitted as a necessary step. Now, just the pure number of other sinter-based approaches makes clear how much broader this possibility has become than binder jetting alone. Along with binder jetting, other metal 3D printing approaches producing a green part for sintering include (among others) powder metal deposition via FFF, lithography-based metal AM, Tritone’s MoldJet process and now Cold Metal Fusion.

Liquid Metal Deposition

Additec demonstrated a hybrid machine tool with multiple metal additive processes. The machine combines CNC machining and DED via laser with liquid metal jetting, the metal deposition capability the company acquired from Xerox.

Another possibility in metal 3D printing that, again, has been present at past shows but now seems to be arriving involves building 3D forms through precisely controlled deposition of drops of melted metal. Additec calls the capability Liquid Metal Jetting — this company is the new provider of the process formerly available through Xerox, and Additec showed it at Formnext on a three-way hybrid machine tool combining this process (good for aluminum and copper) with laser-based wire-arc AM (good for higher-melting-point metals) and CNC machining. The two AM processes both use wire feedstock. A newer variation on the liquid metal process was also shown by the startup Valcun, which calls its process Molten Metal Deposition. Stephanie Hendrixson reported on this in a video that can be seen in our playlist, and she gave this description of Valcun’s process on AM Radio:

Valcun showed these aluminum parts made with its Molten Metal Deposition process. The larger component here (a lampshade) in part illustrates the capability of the process to 3D print 75-degree overhangs.

“[The machine has] a centralized crucible, into which it’s feeding welding wire and melting a large amount of material at once, then this is getting deposited by the printer. The welding wire is cheap, [and the user] doesn’t have to think about storage and transportation challenges like you would with metal powders. And the fact that the machine is printing with normal welding wire means these parts can be welded together, can be anodized, can be treated like any other aluminum part.”

For example, a machine component Valcun showed used the liquid metal 3D printing for a complex section, with off-the-shelf flanges then welded onto it to complete the part.

Control-Based Advances

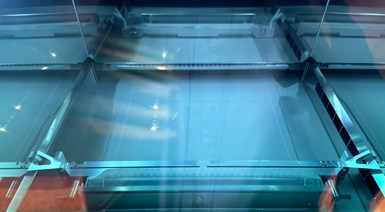

Renishaw demonstrated a significant productivity improvement resulting entirely from a control algorithm. Laser paths that account for the position of the recoater allow for melting and recoating to happen together, instead of each step waiting for the other. This photo conveys a glimpse: The recoater here is in motion, and the laser is at work both ahead of and behind it.

The advances above describe new processes entailing physical changes to materials or machinery, or new ones altogether. But existing processes are also advancing in important ways that involve zero physical change, just changes to control algorithms driving how the additive platform is used. Perhaps the most striking example of this was Renishaw’s introduction of its Tempus control algorithm, which allows its laser powder bed fusion (LPBF) machines to perform laser melting and powder bed layer recoating at essentially the same time, speeding the cycle by eliminating much of the wait time of alternating these steps. In a video report about this advance within our video playlist, I describe it this way:

“[With the Tempus algorithm], the laser is melting the material ahead of and behind the powder recoater arm as it is moving. Another way of thinking about it: The laser is just always scanning the build area of the machine, but the control algorithm keeps track of the position of the recoater at every moment.”

The result is a build time reduction of 20 to 50%, depending on the geometry of the part, again without any physical change to the machine.

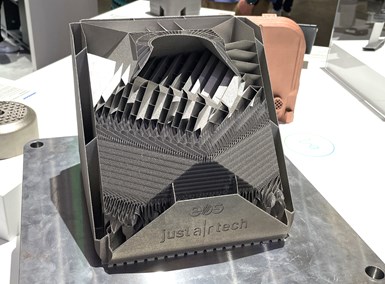

This fractal heat exchanger takes advantage not only of the geometric design possibilities of additive manufacturing, but also the physical capabilities enabled by EOS’s Smart Fusion technology. Without this meltpool management software, the thin walls of this part would not have been possible to build reliably.

EOS has been at this kind of performance improvement as well. Its Smart Fusion system does require hardware, an optical tomography camera for in-process sensing, but with the addition of just this tool, the system allows for algorithmic real-time adjustment of the melt pool to (among other benefits) reduce the need for support structures. The capability has been seen previously, but at this Formnext, the company showed a next step: part geometry requiring this capability. A fractal heat exchanger seen at the show (from Just Air Tech) achieves next-level thermal efficiency using fins just 100 microns thick that are in some cases arranged at extreme overhang angles. The heat exchanger is an example of a part design not just only possible via AM, but in this case also only possible via AM in conjunction with tight real-time control over the laser melting.

Robots for LFAM

This year’s show seemed to mark the arrival of robots as a solution for large-format additive manufacturing. Some companies (like CEAD, seen here) have long exhibited robot LFAM solutions. But robots for large-part 3D printing were visibly more numerous this year.

Control advances also help explain one of the most prominent aspects of the show this past year: the widespread visibility of robots being presented for large format additive manufacturing (LFAM) applications. We have been reporting on this for a long time: Robots and AM naturally go together, in part because the low force involved in material deposition makes it natural for a robot to apply this process (where a robot is far less fitted to higher-force process such as machining). In AM, a robot with a long reach offers an attractive alternative to a machine with a big frame for making big parts.

Still, 3D printing slicer and toolpath generation software tends to assume a box-like 3D printing machine, not the type of motion a robot can provide. This is one of the major areas where technology is changing to favor robot AM. AI Build and Siemens were two examples of exhibitors demonstrating sophisticated slicing and toolpath control specifically for 3D printing with robots.

Postprocessing

An example of the increasing sophistication of postprocessing options, Formlabs’ Fuse Blast is an automated solution for depowdering in SLS. The gun can also be detached from the stand for manual use as needed.

Stephanie observed the maturation of postprocessing evident at the show. She described it this way on AM Radio:

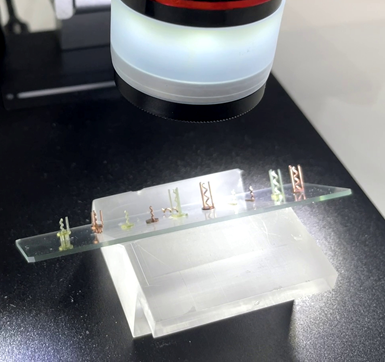

“There were a lot of advances for [the steps] that happen after 3D printing. For a while, I’ve heard people refer to postprocessing as the dirty little secret of additive because it’s very manual — you walk away from this very automated 3D printer that’s producing your part, then there are however many hours of depowdering, cleaning or polishing. [But now we see advances] like Formlabs launching its Fuse Blast, which is for automated SLS depowdering. There were also technology advances about improving the part after printing. For instance, the startup Reinforce 3D, [and its system] which is feeding continuous carbon fiber and resin through parts that can be made through any process, as a way of offering more reinforcement and also joining parts together. Also, Horizon Microtechnologies has this really interesting way of coating very tiny parts by adding copper to a part made through photopolymer 3D printing.”

Horizon Microtechnologies showcased tiny parts made on Boston Micro Fabrication printers that it coated with copper using a proprietary process. These helical resonators are representative of parts that would be used to control energy moving through an antenna.

Postprocessing had a large footprint at the show, she noted — to the extent that it is arguably now not dirty, not little and not a secret anymore.

Copper as a Constituent

Speaking of copper, this one particularly useful metal has been following a long arc as it relates to AM, and we saw the next chapter of its story at this show. Years ago, copper was to a large extent unprintable — poorly suited to metal AM technology at the time. That time is over: Successes with copper 3D printing in binder jetting, LPBF, directed energy deposition (DED) and other processes have led to solid copper 3D printed parts becoming prevalent at events such as Formnext. But a solid copper part is of limited appeal; the best use of copper is as a constituent of an otherwise non-copper part. And that is the next step: Formnext this time showed examples of multimaterial 3D printing of solid parts in which copper is just one material. Siemens, for example, showed a multimaterial success in DED (copper and Inconel) and Nikon SLM Solutions showed a multimaterial success in LPBF (copper and steel).

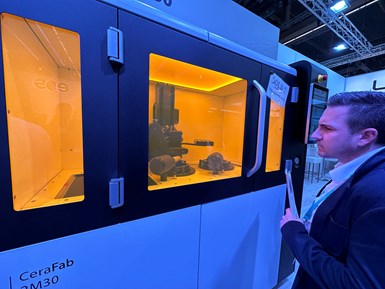

For multi-material builds involving ceramic, Lithoz has introduced a multi-vat lithography process that moves incomplete parts back and forth between two materials. Solid ceramic parts incorporating copper represent one of the possibilities.

An example in digital light processing (DLP) involved a new machine platform. Lithoz, known for DLP 3D printing of ceramic parts, introduced a multimaterial machine with copper as a leading application. DLP is a vat polymerization process, and the company’s new machine employs two vats. The part is suspended from the build tray as it forms, with the tray moving incomplete parts back and forth between the vats to layer together two materials. There are various applications, including parts combining different ceramic formulations, but the most promising application the company sees is the chance to produce hard, temperature-resistant ceramic components for the electronics industry that have copper lines printed through them.

Other examples of copper as a component of solid multi-material parts: (top) Siemens showed a DED combination of Inconel and copper relying on in-process temperature sensing to control for the thermodynamics of the build, and (bottom) Nikon SLM Solutions showed a multimaterial application of LPBF combining copper and steel.

One other development involved integrating copper in a different sense. 6K Additive and Metal Powder Works announced an agreement around copper. The latter company has a system for converting barstock to metal particulate, but for a process like LPBF, the resulting material still needs spheroidizing. 6K, through its Unimelt process, offers an efficient system for spheroidizing rough stock. The two companies have partnered to address the growing demand for raw stock for 3D printing in copper, and together they expect to be able to process copper barstock in response to this need.

On-Ramps to Additive

One final theme we observed relates to where the application successes of the future will come from. Various established providers emphasized new systems aiming to broaden the possibilities for additive by, in various ways, offering accessible on-ramps for current non-users of additive technologies to begin to develop success and experience.

3D Systems’ new SLS machine is office-friendly and fits through a standard doorway. The machine is seen at far right with a powder recycling unit (middle) and depowdering station. (That people are blocking the machine in this photo emphasizes how thin the machine is.)

A few examples: 3D Systems showed an office-friendly machine for SLS. Today, when 3D printing capability spreads widely throughout an engineering organization, the mode tends to be FFF — but the new, slender SLS system seen at the show fits through an office door, perhaps making this capability similarly accessible. At different dimensional and quantity scales, other AM system providers also introduced their own on-ramps. For micro 3D printing, a process with its own distinct design and part handling considerations relative to conventional 3D printing, Nano Dimension launched a starter machine with a build volume under 1 cubic inch (still generous in the context of micro 3D printing) suited to part and process development in micro AM. Meanwhile, back at more conventional sizes and for higher-volume production, Evolve Additive Solutions introduced an e-commerce portal, STEP Parts Now, allowing potential users of the company’s Selective Thermographic Electrophotographic Process (STEP) to begin obtaining production parts made using this high-speed AM approach ahead of committing the part design or equipment purchasing plans to this process.

Nano Dimension’s Giga machine is meant to offer an entry to 3D printing of parts with microscopic features for electronics and other applications. Processes proven here can be scaled up to the company’s existing, larger Terra machine.

On AM Radio, I expanded the conversation about these on-ramps by noting how this emphasis covers developments even beyond equipment and services. I will end the summary with this, noting how Formnext is a venue not just for presenting AM technology, but also for advancing our shared understanding of AM. The Siemens team at Formnext was emphasizing a different sort of on-ramp that I described this way:

“They have a system called AM Navigator that fits right with this theme. It’s something they developed with a lot of partners: DyeMansion, HP, BASF Forward AM, EOS. And all these companies together have conceived this framework for discussing the strategy for additive, defining where a particular user wants to go with it and where they still need to go. [It] takes the form of this set of quiz questions to determine a company’s level of additive deployment in terms of design; materials; process engineering; print setup; manufacturing execution; people and organization — all these different categories and areas of consideration to characterize the level of additive use, and provide this common language for framing aspirations and expectations so that everyone mutually understanding where the organization is trying to go with additive, which is going to be different for different users. The idea is, as more companies affiliated with all these developers of AM Navigator use this system, the set of responses will become benchmarks allowing a company to understand where it’s at in its own additive advance.”

Related Content

Part Removal Efficiency In a 600 mm Plus World

Clay Olson of EDM Performance Accessories discusses the difficulties and opportunities in cutting off parts from the build plates of large AM systems. Molybdenum wire EDM offers an effective solution to the challenge of large-part cutoff.

Read MoreRobot Vs. Gantry for Large-Format Additive Manufacturing (Includes Video)

Additive Engineering Solutions, specialist at 3D printing very large parts and tools on gantry machines, now also uses a robot for large-format AM. Here is how the robot compares.

Read MoreVideo: AM for Repair of Large Shafts

Wind power shafts that might once have been scrapped are now returned to service. See the robotic directed energy deposition (DED) and shaft preheating system developed by Ikergune, Izadi and Talens.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MoreRead Next

10 Video Reports From Formnext 2023

Our Formnext video playlist: Stephanie Hendrixson and Peter Zelinski report on various technologies seen at Formnext 2023 in brief videos they filmed at the show.

Read More8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreCopper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

Read More