Bioceramics for Bone Replacement: The Cool Parts Show #18

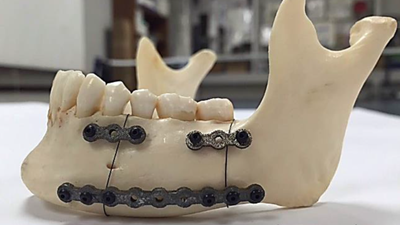

A mandibular cage made up of two different bioresorbable ceramics points to the future of bone graft and reconstructive surgeries in this episode of The Cool Parts Show.

Medical implants like mesh, plates and cages are used in many instances where a patient’s body requires extra support while it heals. But it’s not enough to supplement the strength of human bone; surgeons also need to account for the cancellous tissue, the soft tissue found inside the stiff and strong cortical bone. Cancellous bone graft taken from a patient’s own body and applied inside an implant is one way to encourage in-growth; artificial bone represents another.

In this episode of The Cool Parts Show, we look at a proof-of-concept solution from Lithoz in which 3D printed bioceramics take the place of both cortical and cancellous bone. The mandibular cage shown features a zirconia cage to provide strength and stability, plus inserts made from tricalcium phosphate (TCP) that serve as artificial bone graft. All were made using Lithography-based Ceramic Manufacturing (LCM), a digital light processing (DLP) technique. | Season 3 of The Cool Parts Show brought to you by Carpenter Additive

The Cool Parts Show is a video series from Additive Manufacturing Media that explores the what, how and why of unusual 3D printed parts. Watch more here.

Have a cool part to share? Email us.

Resources and links

- Lithoz’s research on replacing both cancellous and cortical bone with bioceramics

- The Cool Parts Show season 1 episode on 3D printed spine cages

- More on 3D printed implants and other medical applications

Transcript

Stephanie Hendrixson

Most implant-related surgeries require two things; the implant itself and bone graft, which is usually taken from the patient's own body. Could 3D printing be a solution to both? We'll find out in this episode of The Cool Parts Show.

Pete Zelinski

Season Three of The Cool Parts Show is brought to you by Carpenter Additive. The company's Athens, Alabama, Emerging Technology Center is an end-to-end additive manufacturing production facility with everything from material development to postprocessing under one roof, ready to help you with your next metal 3D printing job. Check them out at CarpenterAdditive.com. Now back to the show.

Pete Zelinski

I'm Pete.

Stephanie Hendrixson

I'm Stephanie.

Pete Zelinski

Welcome to The Cool Parts Show.

Stephanie Hendrixson

This is our video series where we talk about cool, unique, interesting 3D-printed parts. So Pete, today we are going to talk about implants; specifically this mandibular cage. So this is an implant that you would use if you had kind of a large area of bone missing from your jaw as a result of cancer or some kind of trauma. But before we dig into this, let's just kind of start with the basics. So, why do we use implants in our bodies?

Pete Zelinski

So you referred to some kind of serious issues, some trauma, so I guess an implant — it takes the place of bone, right? It does what the bone should do if it's not injured or damaged in some way. So we put an implant in our body to support the weight, take the load that the bone isn't doing right now.

Stephanie Hendrixson

Yeah, and if you kind of take that like one step further… Previously, when we've talked about implants, we talked about a spine cage and the titanium spine cage was providing that kind of like strength and stability like what you're talking about, but it's also a place for the surgeon to pack in bone graft to help the patient's body heal. And so the implant that we're talking about today actually serves both of those purposes. So this is a three part implant. It's two different materials. And so there's this stiff outer cage that's providing that strength and stability, and then there are these two inner scaffold pieces that are sort of serving the same purpose as the bone graft. It's basically artificial bone.

Pete Zelinski

Okay, so what I just said about the implant taking the place of bone, there's actually — there's a present and a future component of that; in the present, this outer form — the cage — does the very best it can to support the weight of the bone and hold it together. But that cage is containing something, it is containing a bone graft. And eventually it is bone itself that takes the place of bone and that's what the implant is trying to get to. And now we're looking at an implant that accomplishes both of those. And I'm seeing… They're not the same, these two components you just showed. I'm noticing at the very least they are two different colors. Talk about that— what's going on there?

Stephanie Hendrixson

Right, so two different materials for the cage and the inner lattice. These are both ceramics. They're what are called bioceramics, and they're biocompatible.

Pete Zelinski

Stop there. So first time on The Cool Parts Show we've talked about ceramics as a material that you can 3D print with. I want to learn more.

Stephanie Hendrixson

Yeah, so these are actually pretty interesting materials. This outer cage, the strong part of the implant is zirconia. And then these inner pieces are a material called tricalcium phosphate. So all of these parts were printed by a company called Lithoz, who you might know for specializing in ceramic 3D printing. So I want to introduce you to Dr. Daniel Bomze, who is the head of the medical business unit at Lithoz. So here he is explaining a little bit more about the materials used in this implant.

Dr. Daniel Bomze

So we selected here two different ceramic materials. In this case, the outer shell was made of zirconium dioxide, or in short; zirconia. And it should give the body support during the healing phase and stabilize the artificial bone defect. Basically, the two parts of the jaw should be stabilized with something that has very good mechanical properties. And the inner part of this implant here, it was made from tricalcium phosphate. This material has very similar composition as the inorganic fraction of human bone. So, therefore, it allows for very good cell attachment, which is important for in-growth of blood vessels and supply of the bone cells with nutrition and oxygen. Finally, one of the most important properties of tricalcium phosphate is it can be resorbed by bone cells. And afterwards, this material that has been resorbed can also be used to build up new, healthy bone by other cells. So, therefore, we are speaking here of tricalcium phosphate— of a bioresorbable bone replacement material. And by combining a very high strength, very rigid material which would give the proper stability during the healing phase — in this case, the zirconia cage — and the bioresorbable material that helps the body to form new healthy bone — in this case, the tricalcium phosphate — we combine here solutions from the best of two worlds.

Pete Zelinski

So he said resorbability, right? Suggesting that this inner part of the implant, it goes away. It is absorbed back into the body, it disappears so that bone takes its place.

Stephanie Hendrixson

Right, so it's kind of just this initial scaffold that's going to allow your cells to grow back in and then over time, your bone would replace this. So this inner portion is not something that would be in your body long term.

Pete Zelinski

Wow. Is it just for jaws?

Stephanie Hendrixson

No. So Dr. Bomze says, you know, this isn't something that we would use to replace a hip cup or something, but the ability to print artificial bone like this would be useful anywhere that you have a large section of bone missing, especially a delicate area like your jaw or your eye socket.

Pete Zelinski

So the material is important, right? It's very important, but the process is important too. How were these 3D printed? What is the 3D printing process?

Stephanie Hendrixson

Yeah, so the process for both of these is lithography-based ceramic manufacturing using a Lithoz CeraFab printer. And so it's lithography based— usually that means you're using light to cure a photosensitive resin. And in this case, the material is actually that polymer resin, but it has ceramic powder inside of it. And so as you're curing it, you end up with this composite part that has the ceramic and the polymer, and then you later sinter out the polymer, so you end up with just the ceramic. And we should say that these are both built in separate builds using different materials and then assembled together after the fact.

Pete Zelinski

I can't help but notice— like what 3D printing helps you achieve is this geometry that is customized. We talk about customization a lot but this perfectly matches this hypothetical patient's jaw. How do they get the geometry? How do they get the exact form of the patient's bone, body that way?

Stephanie Hendrixson

Yeah, so 3D printing allows you to make a custom implant like this for any particular patient. What they are actually able to do is use data from like a CT scan or an MRI and design the cage and the inner lattice exactly to fit the patient. So this is a really good solution. Especially if you have a patient that has like a congenital condition or some kind of special anatomy, where an off-the-shelf implant may not be a really good fit.

Pete Zelinski

Yeah. Okay, so one 3D printing process produces both the inner and outer, the present and future components of this implant. From a manufacturing standpoint, that's efficient. From the standpoint of the surgeon, that's efficient. You mentioned the patient. I suspect the impact of this is even greater than those efficiencies I'm describing.

Stephanie Hendrixson

Yes, especially if you think about how a surgery like this would normally progress. So the gold standard right now is to use bone graft from the patient's own body. Usually they take the bone graft out of your hip. And so that means you're having another surgery, you're going to be an additional pain, there's additional risk for complications. And you may not end up with an implant that fits you all that well. So I want to show you another implant. So this is a titanium plate. This is something that might be used in a jaw reconstruction surgery and like it doesn't really fit the geometry in the same way that this customized implant would. So here's Dr. Bomze again, just describing what the process would be like with a more conventional implant.

Dr. Daniel Bomze

Conventionally, the patient needs material that has to fill in the gap, and usually you would take autologous material for that. Autologous material in this respect means bone from same patient, so from another part of the patient's body, and this has to be transplanted then to the jaw. Furthermore this obtained bone material has to be shaped so that it perfectly fits and bridges the defect properly which is another step that the surgeon has to do. And finally, you have to stabilize the two bone fragments, as well as the new bone graft, in place. For that purpose, we usually take titanium plates — so-called osteosynthesis plates — for example in my hands, and these have to be manually shaped, and then fixed with screws at the ends of the bone. You see that it will not fit perfectly to the bone so the surgeon has to bend it until it perfectly fits. You do that in the operation theater. But this material is kind of elastic; it's metal, so therefore, after some time, it might happen that the plate bends unintentionally in the opposite direction and therefore worsens the result. Ceramics, however, do not possess elastic behavior and therefore are not prone to this adverse effect on the patient.

Pete Zelinski

Alright, so how far along is this?

Stephanie Hendrixson

Okay, so nobody is walking around with an implant just like this in their body just yet. Both of the materials have been used in humans successfully before, and there is a clinical study that's ongoing with implants that are kind of like this — that are made out of the tricalcium phosphate material — but they're being used in non-loadbearing situations. So you wouldn't need a cage in that situation. But Dr. Bomze says like this study is progressing, the results are positive so far. So it may not be that long before we see a solution like this actually out in the medical field.

Pete Zelinski

Okay. So another example of the kind of changes, the kind of improvements, the kind of advances that 3D printing is bringing. I think I got this. Let me try. This is a two-material implant. In the short term, in the present, this outer cage provides support. And this outer cage, in this case, is zirconia. The inside of this implant, what's inside the cage — which would normally be packed with bone graft — it is instead filled with this different ceramic tricalcium phosphate. And it has a geometry that facilitates and encourages the patient's bone to grow into it. It provides support in the short term just long enough for it to do that, but then this particular ceramic is resorbable back into the body and the bone should grow in entirely and take its place. This makes the surgery much easier on the patient because bone does not have to be harvested in a separate surgery in order to fill the cage.

Stephanie Hendrixson

Yeah, I think the other kind of interesting thing about this— you know, sometimes on the show we talk about things that are kind of proof of concept parts, and this is an example of one; it's not out there in production, yet. But the promise that Lithoz sees in having like this model out here and having this example, it's a really valuable way of getting surgeons, getting medical device companies to start thinking about 3D printing, to start thinking about these bioceramic materials and kind of imagining the possibilities.

Pete Zelinski

Excellent, so powerful. Thank you. I think that concludes our episode. Thank you for watching The Cool Parts Show.

Stephanie Hendrixson

If you have a cool part that you'd like to see featured, email us: CoolParts@AdditiveManufacturing.media.

Pete Zelinski

Don't forget to subscribe. We'll see you soon.

Pete Zelinski

Thank you to our sponsor Carpenter Additive. Listen to additive manufacturing podcasts, attend webinars and learn more at CarpenterAdditive.com.

Related Content

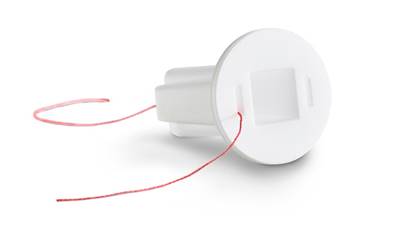

More Affordable Suture Anchors 3D Printed from PEKK: The Cool Parts Show #60

Selective laser sintering (SLS) of polyether ketone ketone (PEKK) is being used to produce medical implants that are more cost effective and perform better than their conventional counterparts. We highlight fasteners known as suture anchors in this episode of The Cool Parts Show.

Read More3D Printed PEEK Spine Implants in Production: The Cool Parts Show Bonus

Curiteva is using Fused Strand Deposition to produce two different lines of FDA-cleared spine implants. We visited the company’s Huntsville, Alabama, facility to learn more.

Read MoreProduction AM Demands Process and Procedures — More Machines Will Come Later

Arch Additive has transitioned to full production of implants made through electron beam melting. The transition has involved practices and personnel, not equipment. As customer products win approval and go to market, here are 5 operational moves the AM implant manufacturer has made.

Read MorePrinterPrezz/Vertex Manufacturing Rebrands to Zeda

The rebranding is said to reflect the company’s “Z to A” approach, which means it starts first with the customer in mind and ends with a product.

Read MoreRead Next

Printing End-Use Parts from High-Performance Ceramics

The lithography-based ceramic manufacturing (LCM) process allows the cost-effective production of ceramic parts even for a batch size of one.

Read MoreAdditive Manufactured Fixation Plates Match Stiffness and Shape of Patient’s Jaw Bone

Research shows that NiTi fixation plates manufactured with controlled porosity using SLM can be matched to the stiffness of a patient’s lower jaw bone as well as its shape.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read More

.jpg;width=70;height=70;mode=crop)