Articles

Video: Inside the Penn State Additive Manufacturing Master's Program, Part 3

Alan Suarez Garcia, advanced manufacturing engineer at GE Healthcare and master's student at Penn State, explains how this degree program changes how he looks at manufacturing.

WatchAdditive Manufacturing for Large Parts

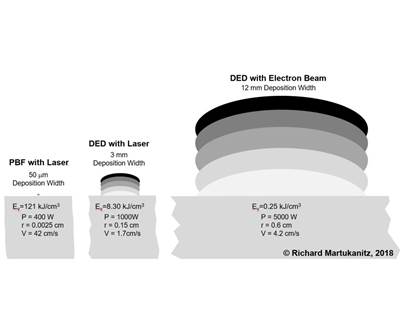

Powder-bed fusion is driving the hype for additive manufacturing right now, but it may not be the best answer. Directed energy deposition is a strong contender.

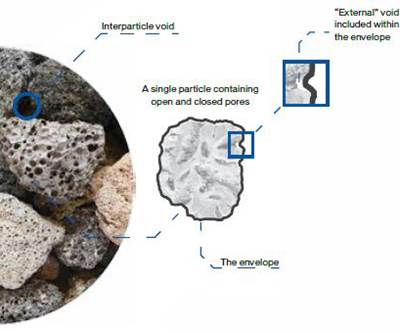

Read MoreDensity Parameters in AM: Measurement and Relevance

For powder material used in additive manufacturing, “density” has various meanings. The different density definitions are useful in different ways.

Read MoreRecap: The Additive Manufacturing Workshop for Automotive

The inaugural AM Workshop for Automotive at the North American International Auto Show brought together the world’s top automotive and additive manufacturing technology experts on one stage. Here’s what they had to say.

Read MoreInside the Penn State Additive Manufacturing Master’s Program, Part 1

PSU's engineering master's degree in additive manufacturing and design offers students and manufacturing professionals a higher education in a continuously maturing field.

Read MoreWhy GM’s Electric Future Is Also an Additive Future

Production capacity isn’t the only reason that additive has been slow to make inroads into the automotive industry. There is a larger barrier to entry—one that General Motors and Autodesk are working to overcome.

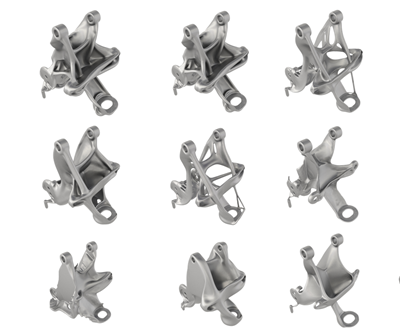

Read MoreHow Topology Optimization Could Be the Key to Longer-Lasting Hip Implants

Hip stem implants must support the mechanical loads of the patient’s lifestyle, but should also avoid stress shielding. A team from Altair leveraged simulation, topology optimization and 3D printing to design an optimized hip stem that meets both conditions.

Read MoreVideo: Inside the Penn State Additive Manufacturing Master's Program, Part 2

A conversation with Brad Hanks, Ph.D. student at Penn State University, illustrates the intersection of optimization and AM with the example of an electrode for cancer treatment surgery.

WatchTop 10 Stories of 2018

Additive manufacturing's advance into production, metal 3D printing and machine learning top the list of this year's most-read stories.

Read MoreStaff Picks: Our Favorite Stories from 2018

Additive Manufacturing editors share their favorite stories of AM users, 3D printing applications and adjacent technologies from the past year.

WatchOptions for Finishing and Postprocessing Metal 3D-Printed Parts

There is a host of technologies available for finishing and postprocessing your AM parts. This column identifies options beyond machining.

Read MoreUpdate on Evolve: Ensuring Repeatability, Reliability and Speed for Scale Production

Engineering the machine and process to work as consistently as production hardware ought to perform is where the company says its efforts have been focused.

Watch