Micro 3D Printing Slashes Costs, Lead Time for Medical Part

Micro 3D printing enabled AntiShock to produce a small-dimension, high-detail part with greater accuracy than SLA and at 20% of the cost of CNC production.

Dmitri Khalilov, cofounder and CTO at AntiShock Labs.

Photo Credit: 3D Evaluate

AntiShock is a medical device start-up company whose headlining product is a disposable, non-invasive, continuous monitoring system that measures patients’ systemic fluid responsiveness to prevent intravenous fluid (IV) overload. Fluid overload is a common condition among intensive care unit (ICU) patients that can cause organ failure and, in severe cases, death.

To further improve its solutions to this problem, AntiShock is developing an electro-optical sensing medical device based on a tiny electro-optical sensor. This sensing device is built out of several small mechanical moving components with high strength and accuracy requirements. Therefore, to validate its product and produce a working prototype device, AntiShock turned to advanced manufacturing technologies.

AntiShock initially considered CNC machining and the stereolithography (SLA) 3D printing process that created the first product mock-up. However, when confronted with the need to produce a small-dimension, high-detail component about 1 mm in diameter, available SLA technology could not provide the required levels of details and accuracy. CNC machining could produce these parts, but the resulting per-part cost was expensive.

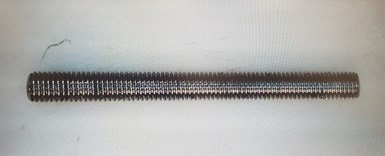

The threaded screw inside AntiShock’s medical device. Photo Credit: AntiShock

Micro 3D Printing

While searching for a solution to this problem, Dmitri Khalilov, co-founder and CTO of AntiShock, came across Nanofabrica’s micro 3D printing system. Curious and intrigued, Khalilov made contact with Avi Cohen, Nanofabrica’s executive vice president of sales, presenting the challenge of producing AntiShock’s small-dimension, high-detail component.

The challenge went beyond printing the component: the part needed a non-standard-pitch thread that could fit a small screw on top of it, the components had to fit each other perfectly, and the final component had to be strong enough to sustain mechanical loads.

After reviewing the part’s size, geometry and thickness, and estimating the mechanical loads the part needed to withstand, Nanofabrica accepted the challenge. Only a few days after delivering a CAD file, the AntiShock R&D received a complete, 3D printed prototype. The team swiftly moved to evaluate the part’s accuracy and verify the production of the required details. The part passed with flying colors — and fit the small metal screw.

The micro 3D printed part for AntiShock’s medical device fit perfectly onto the small metal screw. Photo Credit: AntiShock

The Benefits of Micro 3D Printing

After reviewing the data, AntiShock concluded micro 3D printing offered distinct advantages in various areas.

First, micro 3D printing had the ability to provide the challenging levels of detail and accuracy required, even at resolutions too small for traditional 3D printing. Micro 3D printing also promotes design freedom, and so facilitated the production of AntiShock’s part without many of the design limitations baked-in with conventional production processes. The delivery time for five 3D printed parts was one day, whereas delivery times with CNC would have been between three to four days. Micro 3D printing also saved 80% on costs compared to CNC’s several hundreds of dollars.

Final Conclusions

Less than a week after beginning work with Nanofabrica’s micro 3D technology, AntiShock’s team solved their problem. The possibility of micro 3D printing opened up a wide range of R&D possibilities for AntiShock regarding its existing and future devices. Micro 3D printing also integrated well with AntiShock’s existing to CNC and SLA 3D printing workflow, as these other production methods produced device’s larger parts.

Related Content

Students Use Micro Metal 3D Printing for ISS Microgravity Experiment

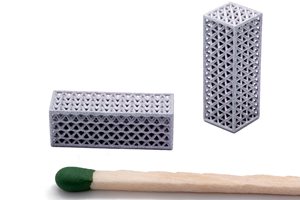

Qualified3D printed lattice parts for the students using microstereolithography (micro SLA), which seemed to be the only process able to produce the parts with sufficient accuracy.

Read MoreLouisville Slugger Uses Formlabs Technology to Accelerate Innovation

Louisville Slugger relies on Formlabs’ Form 3 stereolithography 3D printer to create both prototypes and manufacturing aids for designs of the composite and aluminum bats swung by youth and collegiate players.

Read MoreFizik Utilizes Carbon DLS Technology for One-to-One Program, Creating Customized Bike Saddles

Fizik’s customized bike seat program uses Carbon’s Digital Light Synthesis technology and personalized rider data to create a line of truly custom saddles, giving bike riders the best bike seat for their posterior — only made possible through additive manufacturing.

Read MoreFormlabs’ Form 4 3D Printer Offers New Levels of Reliability and Speed for Stereolithography

The Form 4 is designed to deliver most parts in less than two hours, offering users a powerful, affordable tool to bring ideas to life at fast speeds with excellent reliability, print quality and ease of use.

Read MoreRead Next

Crushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More