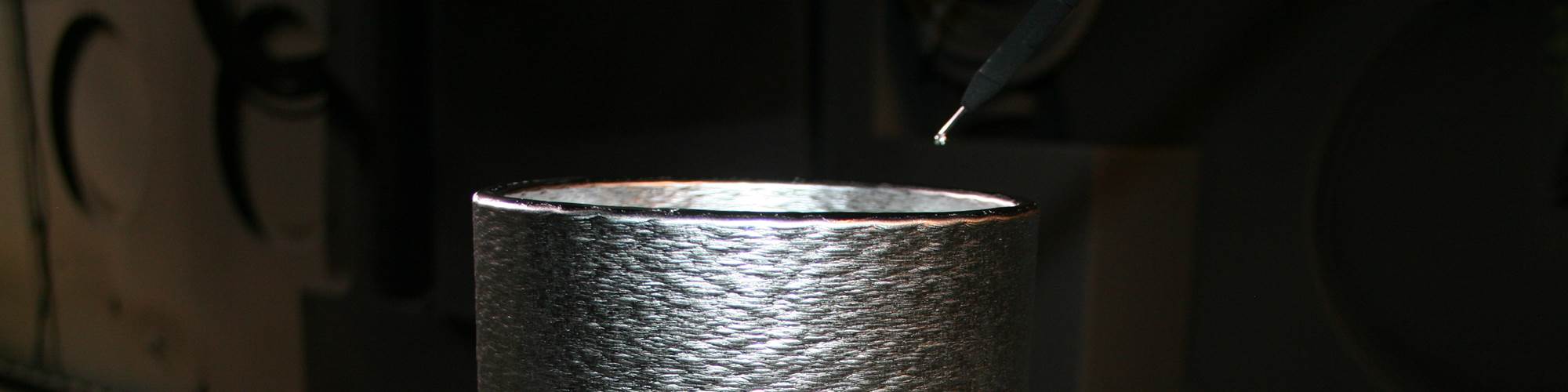

Sciaky’s Electron Beam Additive Manufacturing (EBAM) is a directed energy deposition (DED) process that uses wire input material and an electron beam, enabling gross deposition rates of up to 25 pounds of metal per hour. This makes it ideal for quickly producing large parts.

Photo Credit: Sciaky Inc.

Electron Beam Additive Manufacturing (EBAM) is a metal 3D printing process well suited for producing large parts quickly. This process, developed by Sciaky, allows for gross deposition of up to 25 pounds of metal per hour on machines able to produce parts as long as 19 feet. However, the process needs to be tightly controlled to ensure that the geometry and material properties of the part are consistent. A combination of machine vision and process control algorithms has enabled users to address problems as they occur, but with the addition of artificial intelligence, the system could be able to predict these problems before they occur and adjust parameters to prevent them.

What is EBAM?

EBAM is a directed energy deposition (DED) process that uses an electron beam as its energy source instead of a laser. The use of wire input material (instead of powder) combined with the efficiency and high power of the electron beam (up to 42 kW), enables EBAM’s high deposition rates, says John O’Hara, global sales manager at Sciaky.

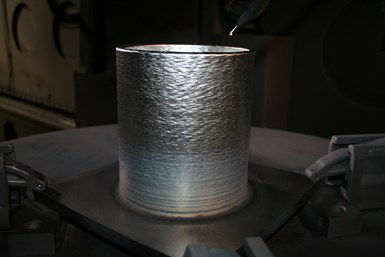

However, the challenge with DED processes is controlling temperature. As the part is built up, the deposition process adds more and more heat to the part. “We have a different thermal situation from the beginning of the part to maybe four or five hours into making the part,” O’Hara explains. This can cause inconsistencies in the shape and material properties. “We want the geometric consistency so that every layer that we create is the same width and the same height,” he says. “We want consistency in how hot that metal gets, and most importantly, how quickly it solidifies.”

As parts are built up in DED processes, more heat is added, which could potentially affect its geometry and material properties. Finding a way to control temperatures is key to making consistent parts with DED. Photo Credit: Sciaky Inc.

Consider a user is creating a part with a layer width of 1/2 inches and a layer height of 1/8 inches. Using the same beam power throughout the entire build will cause the new layers to get hotter and hotter. Eventually they’ll overheat to the point that the metal will flow, creating wider, thinner layers.

The maximum temperature that the material reaches will also affect its cooling rate. This will determine its microstructure and therefore its properties. For example, if the first layer takes 10 seconds to cool while a later layer takes one minute, then those layers will have drastically different cooling rates. “For many of the alloys that we work with, that really matters,” O’Hara says.

IRISS

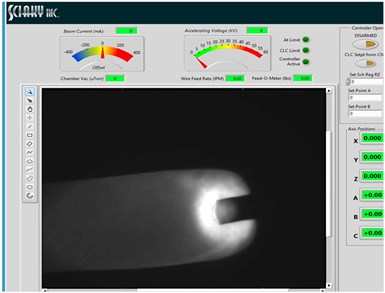

In order to help address these issues, the company developed a closed-loop control system called Interlayer Real-time Imaging and Sensing System (IRISS). This control uses machine vision and analysis tools to make real-time adjustments to the EBAM process at a rate of between 20 to 30 times per second. It looks at the melt pool, directly measuring values like its size and shape, thus indirectly measuring the temperature by analyzing the data collected. “We're able to compare these measurements to expected values and make adjustments to the inputs of the process in real time,” O’Hara explains. If, for example, the system detects that the melt pool is getting too hot, it can slow the process down, or reduce the power of the electron beam so it’s not putting as much energy into the part. It can also increase the wire feed rate so that more energy is being used to melt new material.

Sciaky’s Interlayer Real-time Imaging and Sensing System (IRISS) is a closed-loop control that uses machine vision and analysis to respond to problems as they arise and adjust parameters accordingly. The company is now collaborating with NASA to add artificial intelligence to the control, enabling it to predict problems before they happen. Photo Credit: Sciaky Inc.

Adding AI

Sciaky is currently working on expanding the capabilities of IRISS by adding AI, thanks to a Small Business Innovation Research (SBIR) grant from NASA, which has a strong interest in this area because of EBAM’s application to large components of spacecraft.

The project is still in its beginning stages, and the team is still deciding how AI might expand upon existing capabilities to detect or prevent error. Among the possibilities are allowing AI to guard against the danger of rarer process anomalies such as material contamination and material layers distorting into unusual geometry. Using the existing image collection of the IRISS system, the new capabilities will consist of new software with some hardware additions, O’Hara says.

The company is currently in phase one of the project, which will result in a report or paper before the end of the year. Phase two will involve a prototype system. Phase three will result in a product or feature ready for implementation — available to NASA, as well as other users interested in precise production 3D printing of large-format metal parts.

Related Content

Savage Automation Delivers 3D Printed Commercial Manufacturing Aids

The company's approach to designing end-of-arm tooling and other devices has evolved over the years to support longevity and repairs.

Read MoreVideo: Construction 3D Printing with Robotics, Geopolymer

Alquist 3D is aiming to revolutionize construction and infrastructure with large-format robotic 3D printing using a carbon-neutral material.

Read MoreHow Avid Product Development Creates Efficiencies in High-Mix, Low-Volume Additive Manufacturing

Contract manufacturer Avid Product Development (a Lubrizol company) has developed strategies to streamline part production through 3D printing so its engineering team can focus on development, design, assembly and other services.

Read MoreUltiMaker Targets Light Industrial Applications With 3D Printer Designed for the Factory Floor

The company’s Factor 4 3D printer introduced this week is designed to complement conventional manufacturing equipment including CNC machining and automation.

Read MoreRead Next

The Possibilities of Electron Beam Additive Manufacturing

With dual-wire material feed now allowing for options including blended metal alloys, the metal-deposition process for large-part additive manufacturing continues to forge ahead.

Read MoreVideo: What is Directed Energy Deposition?

DED is an additive manufacturing process that builds features or parts in metal by placing material where needed.

Read MoreLockheed Martin: Importance of Closed-Loop Control in AM

Process repeatability will enable the satellite maker to apply additive manufacturing to the production of critical parts.

Read More