Additive manufacturing (AM) has the capacity to create eye-catching, head-turning designs in everything from engine mounts to eyewear. But sometimes the best design is the one that is practically invisible — at least for now.

“We are starting off with this shoe that is very familiar,” says Gaia Giladi, cofounder and chief creative of footwear startup Hilos. “It has some unique components in the heel and the upper shape, but it also has a sense of familiarity where you look at it and feel like, ‘I can wear that,’ or ‘I can see my friends wearing that.’”

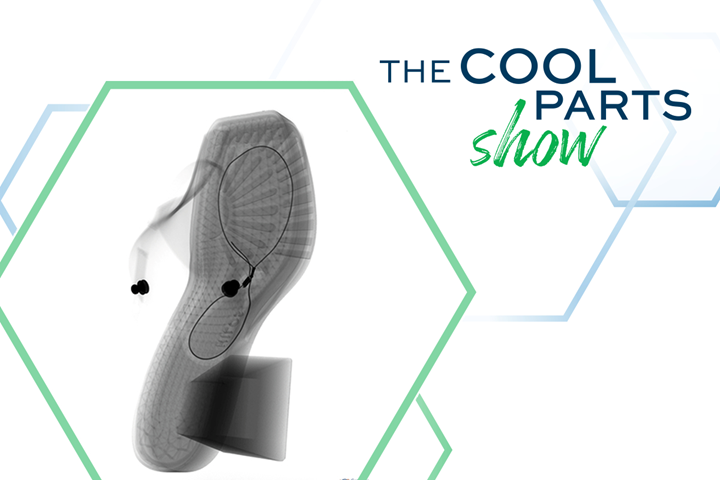

Hilos’ Georgia heels, in Wasabi. Each pair of shoes is custom made on-demand, combining a leather upper with a 3D printed TPU platform. Photos: Hilos

But the relatively simple, accessible appearance of Hilos’ premiere “Georgia” and “Grace” heels conceals a sophisticated construction that brings sustainability, circularity, material frugality and more to fashion footwear — while also providing a comfortable, custom-made shoe.

3D Printing From the Beginning

Some startups begin with an idea and find their way to 3D printing as the solution for making that idea a reality. (Exhibits A, B and C, for instance.) For Hilos, 3D printing was part of the concept from the very beginning. The idea for Hilos originated with Elias Stahl, cofounder and chief executive of the company. Stahl saw an example of a 3D printed accessory at the NY Fashion Tech Lab event in New York City, but believed the technology could be applied to greater effect for creating custom shoes. A mutual friend introduced Stahl to Giladi, a fashion designer experienced in the world of apparel.

Hilos cofounders Elias Stahl and Gaia Giladi show off several different styles of the shoes. Each pair is made in the size and width specified by the customer.

The business got underway in fall of 2019, with Stahl and Giladi relocating to Portland, Oregon, to be closer to this North American shoe manufacturing hub. The two also brought on Eric Folsom, a mechanical engineer, to work on CAD and design for additive manufacturing (DFAM). None of the three had much experience with 3D printing at the outset, or even footwear for that matter.

“I had studied apparel — I had never made a shoe or designed a shoe in my life,” Giladi recalls, “but ignorance is bliss. I think our lack of experience is what helped us in the end to build something that’s truly a new concept, blending what we knew and what we learned with some innovative ideas. 3D printing was a part of it from the beginning because we knew that there were so many advantages, but I don’t think even at the time we realized how many it would have.”

While 3D printing for customization has been utilized in footwear for some time, most previous applications have focused on athletic shoes or corrective insoles. The Hilos team instead set out to create a fashionable shoe that would be comfortable, customizable and possible to manufacture on demand and with minimal waste. The design they created is an open-toed heel with strapped and strapless variations. A 3D printed platform combines the traditional insole, midsole and outsole into just one component; the upper part of the shoe is made from vegetable-tanned leather and connected to the platform without the use of glue.

The 3D printed TPU shoe platform combines outsole, midsole and insole into a single piece with the lattice structure visible here cushioning the wearer’s foot in lieu of foam. A piece of leather covers this structure in the finished shoe.

Joining Old Technique and New Technology

Figuring out how to join these two pieces was a challenge early on. Partners and advisors from other area shoe manufacturers helped Hilos finesse their design and select an assembly method for the shoes.

The final platform design includes hidden internal channels to accommodate the string lasting mechanism.

The key to the construction is a shoemaking technique known as string lasting. The method is an ancient one that utilizes a string or cord to bring pieces together at a seam. The string lasting technique is typically quite complicated, Giladi notes, as usually a single string is used to unite multiple layers of material at once. In a Hilos shoe, the 3D printed platform takes the place of many diverse materials but this consolidation at first made it more difficult to assemble the final shoe. The single unified component did not offer an easy way for the string to wind through and secure the upper.

"We almost gave up on it entirely," she says, "but one of our mentors kept saying, 'You need to think additively about it. Start there.'"

String lasting only began to make sense when the Hilos team approached it from this perspective. Though the 3D printed shoe platform they’ve created looks simple, it conceals internal channels to accommodate the string last (in addition to the latticed footbed cushion that replaces multiple layers of foam and rubber). The leather upper enters the shoe platform through slots on either side and is held in place by a single cord. The result is a minimal design that uses far fewer fasteners and materials than a conventional shoe while maintaining a clean, neat appearance on the outside.

A New Kind of Shoe

With a design in hand, Hilos went on to secure suppliers and officially launched in May of 2021. With the introduction of these first shoes, Hilos has realized the founders’ aims for the product, every one of which is enabled by the manufacturing method. They include:

Comfort. The 3D printed shoe platform is made from BASF's thermoplastic polyurethane (TPU), a flexible polymer more often associated with athletic shoes than fashion footwear. A lattice structure printed into the footbed provides all the cushion the shoe needs, with no extra foam or padding required besides a piece of leather that covers this feature. The result, Giladi says, is a far more comfortable heel than is currently on the market while still being durable enough to withstand daily wear. In mechanical testing, the 3D printed TPU did not fail or break down after a full simulated year.

Customization. With no need for molds or the minimum order quantities these tools typically require, Hilos can offer its custom shoes in a fuller range of sizes and widths than most conventional brands, from 4 narrow through 14 wide. Additionally, Hilos gives customers the option to order different sizes and widths for each foot, recognizing the fact that most people have feet that differ from each other. Because the platforms are 3D printed, there is also the ability to customize the shoe with a seven-character word or message on the bottom of the left sole.

Each platform requires only minimal postprocessing. The chief finishing operation is hydro-dipping to add the wood grain appearance.

On-demand manufacturing. Hilos stocks materials, but not finished product. No shoe is produced until a customer orders it. The 3D printed shoe platforms are made via Multi Jet Fusion (MJF), the powder-based process from HP, at a partner facility. After depowdering and minimal postprocessing, Hilos hydro-dips the parts to add the wood grain and applies protective coatings. The leather upper is trimmed to size and the shoe is then assembled in-house. No excess inventory is created, therefore no excess product will need to be destroyed later if it isn’t sold.

Production with minimal waste. Conventional shoe manufacturing often involves many kinds of materials that must be trimmed to fit, which produces scrap. Hilos uses just a few materials, and relying on 3D printing allows the company to combine outsole, midsole and insole meaning there are far fewer materials and no glue involved. Unused TPU powder can be fed back into the 3D printing process, and leather scraps from the uppers are sent to a partner to be processed into sheets of recycled leather for furniture and other applications.

From Sustainable to Circular

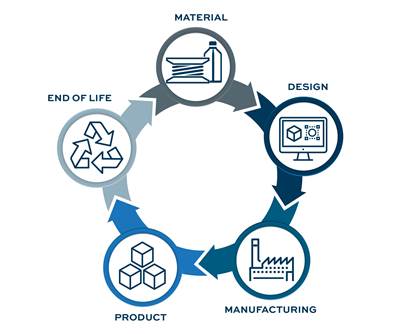

Sustainability was an early goal for Hilos, and one that is within reach thanks in part to its use of additive manufacturing. Compared to conventional footwear, which is typically made from many different materials and produced in bulk (resulting in excess inventory), the Hilos model of custom, string-lasted shoes made with 3D printed platforms is a more sustainable alternative. The company uses a limited number of materials and fasteners, which makes for a simpler supply chain with a smaller carbon footprint. Making products on demand and with an additive process limits waste from production and inventory. It also uses fewer resources in production; Hilos estimates that its total manufacturing process consumes about 85% less water than conventional shoe manufacturing. But Hilos is not stopping at sustainable manufacturing.

"We wanted to be sustainable from the get-go," Giladi recalls, "but as we continued to develop it and talk to people who knew what they were doing, circularity came into play."

Since 2019 Hilos has become interested not just in being a sustainable footwear manufacturer but in creating a circular economy model for its product, a mission that neatly dovetails with the 3D printing-enabled design of its heels. In creating a shoe that is simple to assemble, Hilos had also made it easy to take apart. The string-lasting construction makes it possible to quickly separate the shoe into its different materials by simply snipping the cable that connects the upper to the platform, with no need to peel apart layers or remove adhesives. This simple fact means that these materials can easily be recaptured when the shoe itself has served its purpose and fed back into a manufacturing cycle.

Each Hilos shoe is just a few pieces — a 3D printed platform, leather upper and footbed, and a couple of fasteners. The string lasting method used to hold everything together also makes it easy to disassemble and separate the discrete parts.

Customers can send unwanted shoes back to Hilos for recycling using a shipping label included with each pair (a returned used pair earns a 15% discount on a new purchase). The leather pieces of the shoe, just like production scraps, are chopped up and reformed into sheets of recycled leather for furniture upholstery and more. The 3D printed TPU can be ground into pellets suitable for injection molding. There is no material degradation resulting from this process, Giladi says, which allows the TPU to have a second life beyond that pair of Hilos.

Advancing Circular Fashion Alongside 3D Printing

Hilos officially launched its Georgia and Grace shoes on May 10 (the designs are similar, but Georgia adds straps to the shoe) and has already made a splash in the fashion world, winning the 2021 Glossy Awards category for Best Breakthrough Startup. The company plans to release additional designs in the fall, and in October will launch a collaboration with Helm Boots, an Austin, Texas, manufacturer of boots, oxfords and sneakers for men. Together the companies are introducing a co-branded mule made of leather and TPU to be manufactured utilizing Hilos' circular, print-to-order, digital manufacturing approach. Other similar arrangements will likely follow; the company's mission is not just to advance its own products but to drive footwear (and, potentially, other products) forward using 3D printing.

Hilos currently outsources the 3D printing step to production partners, but later this year plans to open its first lighthouse manufacturing site, the Center of Excellence for Circular Footwear. The facility will be a space for the company and its partners across the industry to work together on applications for on-demand, circular footwear. The intention is to scale a more sustainable footprint for the industry through broad collaboration.

The production process is the first dramatic departure. As yet the design is simple; the defining features for the wearer are the customized fit and comfort. More radical design choices could come later.

But in the near term, Hilos’ focus is on changing the mode of manufacture and the supply chain while providing a new customer experience that is felt rather than seen. The TPU material coupled with the internal lattice of the platform and customization options set these shoes apart more in terms of comfort and fit than appearance. But this is only the beginning. While the outer look of these first shoes is familiar, Giladi sees a future in advancing accessible, circular fashion footwear with the capabilities of 3D printing.

“The feel is completely unique, and the method of making them is completely unique,” Giladi says of Hilos’ first shoes. “But as we continue to build our audience and our reputation, I feel we’ll eventually gain the trust of our customers to push their thinking a little bit farther and showcase the 3D printing more. And that will allow us to push the technology farther, into a direction it hasn’t been yet.”

Related Content

A Framework for Qualifying Additively Manufactured Parts

A framework developed by The Barnes Global Advisors illustrates considerations and steps for qualifying additively manufactured parts, using an example familiar to those in AM: the 3D printed bottle opener.

Read MoreNIOSH Publishes 3D Printing Safety Guide for Nonindustrial Settings

NIOSH has published a 3D printing safety guide for small businesses and other additive manufacturing users such as makerspace users, schools, libraries and small businesses.

Read MoreImplicit Modeling for Additive Manufacturing

Some software tools now use this modeling strategy as opposed to explicit methods of representing geometry. Here’s how it works, and why it matters for additive manufacturing.

Read MoreThe New Misperceptions Of AM: AM Radio #35

Tim Simpson and Peter Zelinski discuss a way additive manufacturing has advanced: The misperceptions have shifted. Knowledge of AM among manufacturers is more sophisticated now. The concerns that inform the perceptions of newcomers have therefore changed.

Read MoreRead Next

Sustainability’s Moment Is Additive Manufacturing’s Moment

The disruption needed by additive manufacturing closely mirrors that required to implement the circular economy. Both can be pursued simultaneously — and the right time is now.

Read MoreCustomizable, Recyclable Shoes with 3D Printed Platform: The Cool Parts Show #37

A 3D printed TPU platform is the key to both comfort and sustainability for these custom heels manufactured on demand.

Read MoreShoe Manufacturing at Flowbuilt Is Reshored and Reimagined

The shoe store of the future is more like a digitized tailor’s shop than a warehouse. Flowbuilt Manufacturing is the flexible contract manufacturer that can serve this vision, using both 3D printing and injection molding.

Read More

.jpg;width=70;height=70;mode=crop)