Share

Read Next

In a recent evaluation of Foundry Lab’s 3D-printing-enabled process for digital casting, Eaton successfully cast three electronics industry components the company currently produces through die casting. The parts were made in the same aluminum and zinc alloys as the die-cast versions, and — also like the die-cast versions — two of the parts featured cast-in-place stainless steel pins that were inserted prior to casting. In a conversation with Cameron Peahl, Eaton’s additive manufacturing manager and leader of the company’s Additive Manufacturing Center of Excellence, he described his observations of this test and what it potentially means for Eaton.

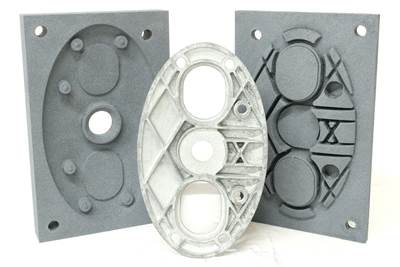

Eaton evaluated the Foundry Lab process with three parts currently made through die casting in aluminum and zinc. Two of the parts (shown) require cast-in-place pins, a possibility of die casting that is also possible in digital casting. Source: Foundry Lab

One of his observations is this: Parts made through the digital casting process are arguably superior to die-cast parts. Specifically, the density is better. This is good and bad, he notes. Better density is obviously better, but the dissimilarity influences Eaton’s view of the process as a potential die casting replacement. Finding a low-lead-time alternative to traditional die casting, yet one that can deliver parts much nearer to die-cast properties and performance than metal 3D printing, is the main promise Eaton sees in the Foundry Lab process.

Digital Casting and Eaton’s Four Pillars

Foundry Lab’s casting process uses 3D printing to get to a metal part which is not 3D printed. The additive process it uses is binder jetting. A temporary ceramic tool (negative of the cast part) is made this way. Then, within a microwave furnace developed by Foundry Lab, this ceramic tool conducts heat to melt a slug of raw material. A cast part is the result, and it can be obtained, including 3D printing the tool, within a lead time of less than a day. Here is a video with more detail on the Foundry Lab process.

So, while the process is casting, it is also additive manufacturing — and it fits within the long, careful journey Eaton is traveling to pursue the promise of AM technologies and develop additive manufacturing for production. There are various, specific reasons for this exploration.

Peahl says, “Eaton thinks about additive in four pillars: prototyping, tooling, supply chain resiliency and [getting a] superior product.” Any meaningful success with AM must entail success in one of these four areas. Digital casting offers the greatest potential within two of the pillars, he says.

One is prototyping. Die casting, with its need for tooling, is a challenging process to apply to making rapid, low-volume prototypes. Metal 3D printing is more responsive and less costly for prototyping, but it produces prototypes that do not match cast properties. Digital casting potentially offers the best of both options: a means to rapidly obtain low-volume parts with properties near to the ultimate casting that will be made in production. The chance to quickly and cheaply make low-volume castings can speed the development and engineering of new die-cast products. He says, “You can go through your product qualification and certifications with the digital process, and even use it for gap production as you build up your tooling.” A prototyping process delivering production-like parts makes this possible.

The other important pillar for digital casting is supply chain resiliency. Peahl says, “It’s no secret die casting is struggling to keep up with demand. Plus, tools are old and they wear out and break, and they are expensive so we generally don’t make spares, meaning we are not ready when something happens. We need to be able to respond to hiccups in our supply chains. That’s where this comes into play.” Further, he says, digital casting provides a potential solution for “the legacy and low-volume production” that casting suppliers are not well equipped to serve.

Digital Casting Vs. Die Casting

How much like die casting is the Foundry Lab process? It is much closer than metal 3D printing processes such as binder jetting and powder bed fusion. The steel pin insertion in the cast parts brings this home. This is a step that is straightforward for casting, including for digital casting, but would be problematic or impossible for the 3D printing processes.

However, the two casting processes are not a perfect match. Eaton’s evaluation showed a coarser grain structure for the digital casting parts versus production parts made through die casting. Also higher density, meaning more consistent filling of the mold for a fully solid part. Peahl says, “The Foundry Lab process heats the entire mold, so there is very good metal flow. It fills the nooks and crannies before cooling begins.” The microwave furnace operating under vacuum also aids in this filling. The resulting improvement plays into Eaton’s understanding and characterization of the process as a potential die casting replacement.

“The superior densities we’re seeing raise a question like, ‘Is this even die casting anymore?’” he says. To serve as a die casting substitute, “Does this part perform too well? I don’t know. But these are the kinds of questions we are asking.” One implication: Perhaps digital casting plays into the “superior product” pillar as well.

Related Content

ConocoPhillips Sees Oil and Gas Supply Chain Opportunity With Additive Manufacturing

Production of parts when needed and where needed can respond to the oil and gas sector’s multibillion-dollar challenge of holding parts in inventory. The supply chain benefit will justify additive even before the design freedoms are explored.

Read MoreSeurat: Speed Is How AM Competes Against Machining, Casting, Forging

“We don’t ask for DFAM first,” says CEO. A new Boston-area additive manufacturing factory will deliver high-volume metal part production at unit costs beating conventional processes.

Read MoreWhy AM Leads to Internal Production for Collins Aerospace (Includes Video)

A new Charlotte-area center will provide additive manufacturing expertise and production capacity for Collins business units based across the country, allowing the company to guard proprietary design and process details that are often part of AM.

Read MoreVelo3D Founder on the 3 Biggest Challenges of 3D Printing Metal Parts

Velo3D CEO and founder Benny Buller offers this perspective on cost, qualification and ease of development as they apply to the progress of AM adoption in the future.

Read MoreRead Next

Aircraft Ducts 3D Printed in Composite Instead of Metal: The Cool Parts Show #68

Eaton’s new reinforced PEKK, tailored to aircraft applications, provides a cheaper and faster way to make ducts compared to formed aluminum.

Read MoreFoundry Lab: How Casting in a Day Will Improve the Design of Metal Parts (Includes Video)

The company’s digital casting process uses 3D printing, but the result is a cast part. By providing a casting faster than a foundry, the company says effective prototyping is now possible for cast parts, as well as bridge production.

Read MoreQualification Today, Better Aircraft Tomorrow — Eaton’s Additive Manufacturing Strategy

The case for additive has been made, Eaton says. Now, the company is taking on qualification costs so it can convert aircraft parts made through casting to AM. The investment today will speed qualification of the 3D printed parts of the future, allowing design engineers to fully explore additive’s freedoms.

Read More