How do we as an industry encourage greater adoption of metal additive manufacturing (AM) and advance the technology successfully into volume production? These questions serve as key goals to drive continued investments in AM technologies.

Metal additive manufacturing was utilized to create Hanwha’s impeller, show above in its finished state. Photo credit: Hanwha Power Systems

While there are extensive examples of small to medium production volumes of non-mission-critical parts, are we ready to meet the specialized and pressing needs of maintenance, repair and operations (MRO) markets? Furthermore, can we accommodate the striking demand for innovative, higher performing designs in aerospace and energy? And will we able to scale up production volume as necessary?

My answer is that we have a way to go.

Despite the rapid pace of advancement across all segments of metal AM, from laser powder bed fusion (LPBF) to directed energy deposition (DED) and metal binder jetting (MBJ), fundamental issues remain. These center around three major challenges: cost, qualification, and development.

Cost and Its Value Curve

Not all components in a final product generate equal performance value. Some features are simply structural (shells and housings) whereas components such as impellers and jet-engine turbine blades require expensive materials, proving more difficult to manufacture and requiring vast engineering resources. However, the value of the more complex components may sell an entire product and be the distinguishing factor from competitors.

Something similar is true of AM, where technology is used to make parts that are not possible by means of casting, machining or alternative conventional manufacturing processes. The ability to create such parts via AM directly equates to value.

Therefore, improved functionality of AM components generally justifies the higher immediate costs. Yet, what will the future of AM costs look like and how should we be thinking about the cost of finished parts?

Utilizing LPBF as an AM cost and value model, we can currently say that material (in this case, powdered metal) makes up approximately 20-50% of the finished part cost depending on the alloy used. Powdered aluminum alloys are less than $50 per kilogram; GRCop-42 can cost more than $300 per kilogram and refractories’ pricing can be several thousand dollars per kg.

Given the wide range of possible engineering decisions, the material to cost profile leads to a metal additive manufacturing part production cost that spans between $150 and $1,000 per kilogram. Yet the question remains: Is this a lot, a little, or just right?

We need to look at value density (value relative to weight and density) to better answer the question. The retail price of a high-end car is around $50,000 and has a weight of 2,000 kilograms, giving it a value density of about $25 per kilogram.

A Boeing 737 MAX passenger airplane, weighing in at 40,000 kilos, has a value density of roughly $2,500 per kilogram. For comparison, the airplane is one hundred times more expensive per kilo than the car.

Although the value of reduced weight in a car may change with new environmental regulations, reduced weight in an airplane remains more critical. Over the lifespan of an airplane, in just fuel savings alone, the use of AM lightweighting and lighter materials such as composites are worth the cost of materials and manufacturing.

The value density formula for a stationary natural gas power plant is not a parallel example to a car or airplane — but improve the efficiency of an energy turbine as AM has done in aircraft engines and the turbine’s component-cost-to-performance ratio is considerably improved. Advanced rocket engine breakthroughs in thrust and efficiency (achieved through AM) have huge economic benefits in fuel savings, lift capacity and increased payloads.

Innovation in these cases directly translates to a higher value per unit of cost. So, with all this value on the table, why is AM adoption not more widespread?

Qualification Factor in Cost, Value, Repeatability and Industry Adoption

We know reducing the costs of AM will continue to improve the technology’s value proposition, but what else will advance the value equation and lead to further adoption? Improved qualification will.

The qualification challenge concerns the ability to generate parts that have reproducible material properties as well as repeatable dimensional and geometric accuracy. When we say repeatable, we mean reproducible from machine to machine, year after year, supplier to supplier.

This challenge has emerged before and was solved by computer numerical control (CNC) machining. A similar solution happens to be just what AM needs to achieve acceptance.

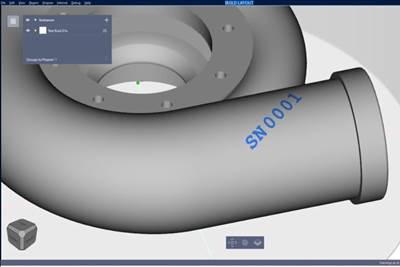

Two IMI oil and gas choke valves (along with material-test coupons) on a build plate after being 3D printed with the Velo3D Sapphire system (2021). Photo credit: IMI and Velo3D

The industry expects akin, reproducible outcomes from AM. That type of proven standard is also a foundation for implementing ongoing improvement and the key to exploring deep innovation for AM systems.

For example, there are hundreds of artisan service bureaus that develop intrinsic manufacturing processes. This “flavored” approach in search of the desired outcome invites variation, but also difficulty in meeting a repeatable specification.

The problem originates in OEM AM machines that contain variability in core processes and controls. The machines experience a “drift” from calibrated specifications over time, meaning print parameters vary from machine to machine. To produce a part on machine B after successfully printing on machine A means starting from scratch in terms of the qualification process.

The same valves from the previous image were printed at six different foreign and U.S. locations in 2022 for a distributed manufacturing project — depicting the use of a common print file for reaching target quality and the potential for scaled production. Photo credit: IMI and Velo3D

Each new part requires process innovation, tuning, and workarounds for every machine used to manufacture that part. In other words, continuous reinvention of the wheel.

How is this cost effective? How is it scalable? Ultimately, how will this lend itself organically to volume production and broader industry adoption?

Developmental Complexity Impacts Training and Education

The challenge with development in AM is closely tied to the issue of qualification. Manufacturing parts requires the development of workarounds and thus uses design for additive manufacturing (DFAM) to produce desired parts.

Today, AM architectural limits force engineers to apply DFAM rules to most designs as a compensation for shortcomings of a system’s print capabilities. Similar to the qualification challenge in conventional AM, where the file must be tweaked and adjusted to the printer, the issue with development means in addition to tweaking the design, new techniques must also be applied to make a part printable.

Rather than ad hoc experimental tweaks to circumvent machine limitations, the approach should utilize software-prescribed, generic manufacturing and universal calibration settings for simplification.

This will directly benefit engineers interested in adopting AM. An intrinsic, built-in quality and inherent process fidelity can serve to satisfy and validate quality. Repeatability and scalability follow.

While it might work for build optimization purposes to use a support structure here and there, when supports hold up almost every aspect of the walls or are needed for internal, otherwise inaccessible geometries for machining once a print is complete, it can become very costly and or impossible to remove.

To avoid these challenges, training and reducing education hurdles is crucial. Such solutions include a push toward applied standards, outside-the-box system fidelity, and greater software automation for the end-to-end quality and build process.

Too many material scientists, process technologists, and PhDs are taking an artisan hand to daily projects. At an operational level, these misdirected human assets drive up costs. This also diverts resources from pure R&D and slows down the broad adoption of AM.

Moving forward, it is beneficial to practice a mindset of “part consolidation and simplification” for the labor and overwrought complexity that currently exists in AM. We certainly know the drill when a customer’s product design sits before us. Might we more strenuously apply some of that knowledge to our own machines?

Moving Toward a Mirror Image of CNC Success

Driving AM to be more like CNC machining is a practical and achievable vision. CNC easily takes on custom and mid-volume production with repeatability, precision and efficiency. It’s the workhorse of the industry, which AM has the promise to become.

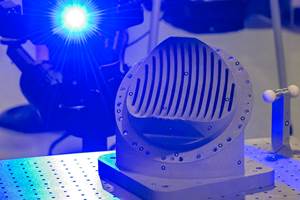

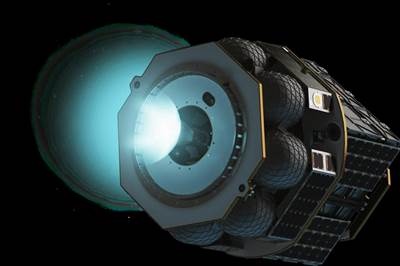

Four Launcher Orbiter engines, additively manufactured with Velo3D’s metal technology. Photo credit: Launcher and Velo3D

CNC is a model for applied automation, hardware-software integration and increasing affordability while improving shop performance.

If AM can conquer its limitations with adherence to tighter specifications, development of uniform parameter sets and greater automation, then it too can reduce costs and simplify qualification of parts.

This will lead to faster adoption in the supply chain and scalability that markets from MRO to aerospace or energy keenly await.

Related Content

AIM3D Study Shows 3D Printing Ultem 9085 Pellets Offers Lower Cost, Higher Tensile Strength

The material qualification testing indicates many benefits of creating components with AIM3D’s ExAM 510 printer using the composite extrusion modeling process, which uses standard pellets rather than the more expensive filaments required by other platforms.

Read MoreDyndrite, MIMO Technik, Astro Collaborate on Machine, Material Qualification for 3D Metal Printing

The companies chose to collaborate on the development of the Mastro process in order to streamline and automate a closed-loop source for additive production and qualification.

Read More7 Takeaways on 3D Printing As a Pathway to Polymer’s Future

The Cleveland section of SPE hosted “Additive Manufacturing: Printing the Path for the Future” on October 17, 2024. Speakers signaled where AM is and where it is headed with session topics ranging from pellet-based 3D printing to qualification and commercialization of additively manufactured products.

Read MoreAdditive Manufacturing in Space: Failing Upward

Not all 3D printed parts destined for space need to adhere to the standards of human space flight. Yet all parts made for space programs require some type of qualification and certification. NASA and The Barnes Global Advisors explore Q&C for these parts.

Read MoreRead Next

Velo3D’s Flow 5.0 Software Enhances Control Over 3D Printing Process

The software’s new features include user-selectable core parameters, preprint analysis to identify potential costly and time-consuming errors, and rapid resequencing for multipart prints.

Read MoreLauncher Uses Additive Manufacturing to Optimize Satellite Design

Launcher depends on Velo3D to 3D print complex rocket compounds for low-cost, small satellite delivery systems.

Read MoreSix Years After Launch, OSU Has a Leading Facility for Metal AM

At the Ohio State University metal additive manufacturing lab, undergraduate students serve as employees on projects aiming to help companies advance with AM. Here is a look inside the facility now running a dozen metal additive systems.

Read More