Prototyping

Carbon’s M3, M3 Max Designed for Faster, Larger, Smoother DLS Printing

The new generation of 3D printers is said to bring faster printing, larger build volume and new capabilities to the Carbon Digital Light Synthesis (DLS) platform.

Read MoreVelo3D Ships First Sapphire XC to Aerospace Customer

The company’s newest and largest metal 3D printer is said to deliver bigger parts, productivity improvements and cost reduction for metal additive manufacturing

Read MoreVideo: Functional Excavator Features 3D Printed Parts

Oak Ridge National Lab's Project AME swapped an excavator's cab, stick and heat exchanger for 3D printed parts. Stephanie Hendrixson and Peter Zelinski get the scoop.

WatchZooming in on Micro 3D Printing: AM Radio #10A

This week on AM Radio, Peter Zelinski and Julia Hider discuss additive at the extremes, including micro 3D printing. What are the opportunities and challenges of 3D printing on a microscale?

ListenDesktop Metal Qualifies D2 Tool Steel for Additive Manufacturing

The company says its Production System binder jetting technology enables production of cold work tool and die parts with high hardness, wear resistance and compressive strength

Read MoreFormlabs Launches SLA Printers, ESD Resin for Optimizing 3D Printing Workflow

The Form 3+ and Form 3B+ were designed to provide speed, quality and workflow efficiency.

Read MoreMold Shop Evaluates Mantle Process for 3D Printing Steel Injection Molds

According to tests performed by Westminster Tool, Mantle’s 3D printing materials behave similarly to traditional steels and hold up well during molding, making them easy to incorporate into existing moldmaking processes.

Read MoreMetal 3D-Printed Implants Are Helping Injured Racehorses

A successful collaboration between Clinique de Grosbois and French service bureau 3D Medical is driving positive outcomes in equine medicine with the development of a new type of prosthesis that improves healing.

Read MoreFarsoon Plans Expansion After Record Sales

Sales record is said to reflect increased growth across Farsoon’s whole product portfolio in both metal and polymer additive manufacturing.

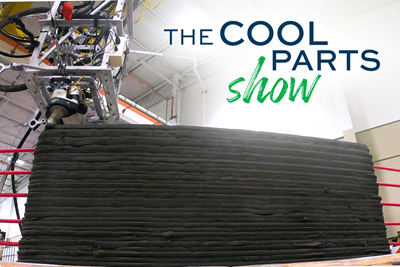

Read More3D Printed Concrete Is Key to This Smart Wall: The Cool Parts Show #40

The SkyBAAM cable-driven 3D printer creates opportunities for embedded functionality in concrete, as demonstrated in this episode of The Cool Parts Show.

Watch