Prototyping

View From My Shop: 3D Printing and Postprocessing With Tangible Solutions

Collaboration between Tangible Solutions’ additive and machining departments simplifies their work. Learn more in this episode of The View From My Shop.

WatchSiemens Partners with ORNL on Additive Manufacturing Research

Joint project focuses on U.S. manufacturing innovation to include additive manufacturing, workforce training and decarbonization.

Read MorePlastics Assembly Expert Joins Development and Production via 3D Printing

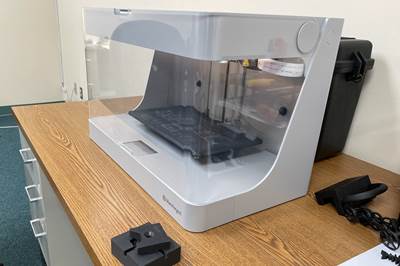

Manufacturing technology supplier Extol has always served customers who are producing polymer parts. Now, it is making some of those parts in-house through 3D printing, providing new options ranging from functional prototyping into bridge production and beyond.

Read MoreLauncher Acquires Solukon Depowdering System for Postprocessing Rocket Parts

The depowdering system removes residual and clogged powder from metal laser-melted parts within a sealed process chamber, using adjustable vibration and automated two-axis part rotation while recovering superfluous powder.

Read MoreAltair Acquires Gen3D

Acquisition expands Altair’s design technology for additive manufacturing.

Read MoreAMGTA Names Sherri Monroe Executive Director

Monroe will be responsible for furthering the the global AMGTA goals.

Read More3DQue Multi-Failure Detection System for 3D Printing

System features a Correction Wizard that suggests fixes and enables operators to set custom automated responses (pause, notify, ignore) for each failure type.

Read MoreCan the U.S. Become Self-Sufficient in Aerospace Alloy Metal Powders?

6K’s technology can upcycle titanium and nickel-alloy parts into additive manufacturing powder. Here is how the circular economy helps national security.

Read More3D Printed Metal Component for CNC Machining Center: The Cool Parts Show #47

Machine tool maker DMG MORI improved this coolant delivery adapter by making the part through additive manufacturing instead of machining. One of the viewer-chosen winners of The Cool Parts Showcase.

WatchAdditive Manufacturing and the War in Ukraine: AM Radio #19

In this latest episode of the AM Radio podcast, we dive into the ways that AM is providing aid and also being affected by the conflict in Ukraine.

Listen