3DQue Multi-Failure Detection System for 3D Printing

System features a Correction Wizard that suggests fixes and enables operators to set custom automated responses (pause, notify, ignore) for each failure type.

Share

Read Next

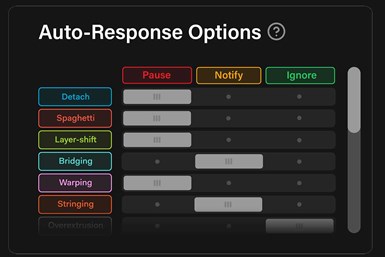

3DQue’s QuinlyVision auto response options. Photo Credit: 3DQue Systems

3DQue Systems’ QuinlyVision is a failure detection system for 3D printing that offers 5-second detection powered by SQUINT (Subpixel QuinlyVision Technology). The system is desigened to detect 14 failures, including warping, layer shift and more. The company says it is an open source system compatible with any printer/camera, requires only minimal system and bandwidth, and can run on any device.

According to the company, the system is packed with features, including AutoCorrect 3D to detect, automatically respond and suggest solutions to 14 common print failures. By combining AI failure recognition with object tracking, photogrammetry and subpixel analysis, the system is said to detect issues in seconds, even in low-light conditions. Users can utilize customizable auto response options, a built-in troubleshooting guide, 24/7 unlimited supervision and secure remote access.

It is said the technology was developed to focus on detection, not correction, in order to simplify failure correction by pinpointing the problem, automatically taking action and providing suggestions to prevent future failures. The company says that getting consistently high-quality 3D prints requires a delicate interplay of design, calibration and slicing. Determining what went wrong, why and how to fix it can be a time-consuming process of trial and error.

By classifying failures and how they develop over time, the built-in Correction Wizard is said to pinpoint root causes such as hardware, slicing or model issues. It provides detailed troubleshooting information right on the dashboard.

Much like text autocorrect, the company says its algorithm diagnoses the problem and suggests possible solutions to save time and frustration. The Autoresponse is said to go even further by enabling different actions (pause, notify or ignore) for each failure type, thereby enabling printers to self-correct the moment an issue is detected.

The 14 failure types include detach, nozzle blob, skirt, under extrusion, over extrusion, zits, stringing, spaghetti, no extrusion, warping, poor first layer, model, poor bridging and layer shift.

Related Content

-

3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

-

Carnegie Mellon Helps Industry, Students Prepare for a Manufacturing Future with AM and AI

Work underway at the university’s Next Manufacturing Center and Manufacturing Futures Institute is helping industrial additive manufacturers achieve success today, while applying artificial intelligence, surrogate modeling and more to solve the problems of the future.

-

Spherene Creates Metamaterial with Geometry Derived from Spheres

An algorithm developed by Spherene Inc. generates Adaptive Density Minimal Surfaces (ADMS) as a self-supporting infill strategy that can be used to reduce mass and manage material properties in 3D printed parts.