Prototyping

3D Printed Putter Tailored to the Golfer: The Cool Parts Show #49

An engineering student in South Africa used metal and polymer 3D printing in tandem to create a putter customized to the individual golfer’s swing.

Watch6K Receives Innovation Grant for Battery Production

The state grant will fund the purchase of one new UniMelt system, a technology designed by 6K that will be used to produce metal powders used in AM and battery material production.

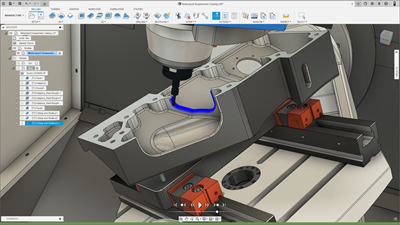

Read MoreAutodesk Fusion 360 Software Enables Generative Additive Manufacturing

IMTS 2022: This cloud-based 3D modeling, CAD, CAM, CAE and PCB software platform for product design and manufacturing is said to help users design, engineer and manufacture products to ensure aesthetics, form, fit and function.

Read MoreVelo3D Qualifies Copper Alloy for Use With Its Sapphire Printers

Velo3D has qualified the NASA-developed GRCop-42 alloy for use with its Sapphire family of printers to deliver the conductivity of copper with high strength for aerospace applications, such as rocket engine combustion chambers.

Read MoreWhere Does Additive Manufacturing Make Sense?

3D printing’s earliest applications were for rapid prototyping. Additive manufacturing (AM) has advanced far beyond this with the maturation of various technologies and expansion of its materials envelope.

Read MoreUltimaker Offers Metal Expansion Kit for 3D Printing

The kit was developed to remove existing process bottlenecks and limitations in printing metal parts, and is compatible with the Ultimaker S5 Platform.

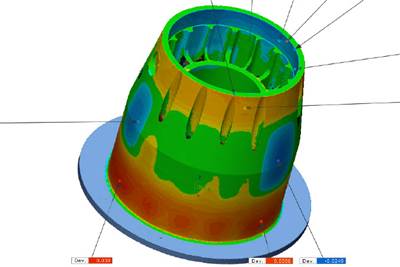

Read MoreHow Does Heat Treating Affect Machining Considerations for a Metal 3D Printed Part?

This picture of part distortion in additive manufacturing illustrates the kind of effects that part design or machining stock allowances need to anticipate.

Read MoreAmnovis, BAAT Medical Collaborate on 3D Printed Medical Devices

Amnovis and BAAT Medical are focused on pushing the innovative edge of medical device OEMs to move faster through the development, validation and manufacturing stages.

Read MoreHow An Airline Addressed Supply Chain Issues with 3D Printing

COVID-19 not only grounded most of Scandinavian Airlines’ (SAS) fleet in 2020, but also limited its access to engine covers critical for safe storage. CNE Engineering used BigRep machines to 3D print molds to produce the covers.

WatchHP, Legor Collaborate on Specialty Precious Metals for Jewelry Markets

The initial collaboration will focus on enabling the production of functional stainless steel accessories for the jewelry and fashion markets, while also implementing an R&D program to parameterize and characterize bronze and silver powders, and eventually gold powders.

Read More