Altair Acquires Gen3D

Acquisition expands Altair’s design technology for additive manufacturing.

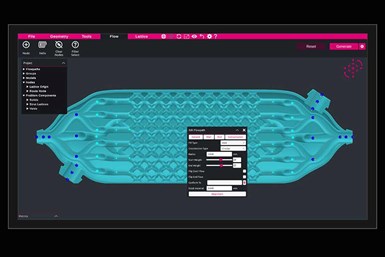

Gen3D’s design for AM software is said to enable engineers to create optimized components that can be manufactured with confidence. Photo Credit: Altair

Altair, a provider of computational science and artificial intelligence (AI), has acquired Gen3D, a startup out of the University of Bath, U.K. Gen3D is a pioneer implementing an implicit geometry method for describing highly complex geometries such as lattice structures in additive manufacturing (AM).

Gen3D’s technology is said to use next-generation implicit modeling techniques to rapidly create complex geometry not practical with traditional boundary representation (BREP) solid approaches. This enables components to be designed simply by specifying the functional requirements for the part (loads, holes for fastenings, keep-out zones, ducts for fluid flow and more). Additionally, the technology automatically filters out component geometries that are likely to cause downstream manufacturing issues, the company says.

Gen3D’s generative design tool is said to empower engineers to rapidly create complex designs while minimizing the risk of in-print failures. It is used by design engineers for applications such as energy absorption, heat transfer, filtration and others across industries such as aerospace, automotive, manufacturing, medical and energy.

“In addition to a powerful technology that helps organizations navigate the challenges of design for additive manufacturing, the Gen3D team brings deep industry knowledge and experience in advanced additive design techniques such as generative design, topology optimization and lattice structure generation,” says James R. Scapa, Altair founder and CEO.

The technology will be integrated into Altair Inspire, which the company says is an intuitive, powerful family of software products that enables simulation-driven design throughout the entire product development life cycle, from concept to reality. When used early in the design process, it is said the Inspire technology empowers the creation of designs that are focused on both performance and manufacturability, and empowers its users to explore, develop and manufacture high-performance products in a single intuitive development environment.

Related Content

-

Semiconductors, Tungsten, AM Affordability and More from Formnext 2024: AM Radio #56

The trade show included increased applications for the semiconductor market, machine launches and technology advances aimed at cost cutting, plenty of LFAM and more. Listen to our conversation on Formnext 2024.

-

User-Friendly Mass Spectrometry Tool to Enable AM

The Massbox is a technology designed to simplify mass spectrometry by bypassing the need to send samples to the lab for characterization and testing purposes. Exum Instruments’ debut tool is suitable for AM as it can assist with quality assurance, material characterization and failure analysis.

-

Robot Vs. Gantry for Large-Format Additive Manufacturing (Includes Video)

Additive Engineering Solutions, specialist at 3D printing very large parts and tools on gantry machines, now also uses a robot for large-format AM. Here is how the robot compares.