DyeMansion Delivers 1,000th Machine to Zeiss Vision Care

The machine will be used at Zeiss Vision Care’s Aalen, Germany, site to additively develop and manufacture tools and components for the production of individual precision eyeglass lenses.

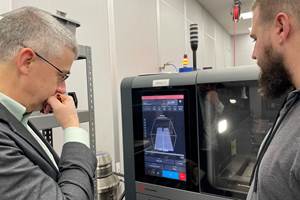

DyeMansion co-founders Philipp Kramer (CTO) and Felix Ewald (CEO) in front of the 1,000th machine, a Powerfuse S, before it was delivered to their customer Zeiss Vision Care. Photo Credit: DyeMansion

DyeMansion, a provider of postprocessing solutions for industrial plastic 3D printing, has marked a significant milestone with the sale and delivery of its 1,000th machine. “I am incredibly proud of this milestone and what it represents,” says Felix Ewald, DyeMansion CEO and co-founder. “We are not just selling machines, we are paving the way for a new era of production and the industrialization of additive manufacturing.”

The 1000th machine is a Powerfuse S, the company’s advanced vapor smoothing system for highly industrial manufacturing delivered to Zeiss Vision Care. Zeiss operates in the ophthalmic industry, providing lenses, instruments, applications and platforms to opticians, retailers and optometrists in more than 60 markets worldwide. Organic prescription and photochromic lenses are developed and produced at its Aalen site. The plant also develops manufacturing technologies and Industry 4.0 applications that are used in prescription production at Zeiss worldwide.

“We chose the Powerfuse S from DyeMansion because the system is perfectly tailored for finishing our 3D printed plastic parts,” says Andreas Dangelmaier, head of engineering design at Zeiss Vision Care “For use in our cleanroom environment, the surface quality requirements are extremely high. At the Aalen site, we additively develop and manufacture, among other things, tools and components for the production of individual precision eyeglass lenses. For this, Industry 4.0 capabilities, precision and connectivity of the DyeMansion system are indispensable. Of course, we also particularly like the sustainability aspect due to the nontoxic and biodegradable polishing medium."

The 1000th system was sold through DyeMansion sales partner Solidpro. Based in Langenau, Germany. Solidpro joined DyeMansion’s Global Partner Platform in March 2020. It has been supporting more than 7,000 customers with PLM and 3D printing solutions since 1997 and offers a holistic approach to realizing products along the entire product life cycle. From startups to large corporations, Solidpro offers a portfolio of services and solutions — from 3D CAD design to additive manufacturing —to give companies the tools they need to turn their ideas into reality. As part of the Bechtle Group, Solidpro is positioned for the future and benefits from working together in a large network.

Founded in 2015, DyeMansion has grown exponentially and now boasts a team of 95 dedicated employees who share a vision of enabling the era of digital manufacturing. The team started with the introduction of the first industrial coloring solution for SLS parts and since then has continuously expanded its portfolio.

“I want to express my heartfelt thanks to all our team, our customers and partners who have placed their trust in our technology over the last years,” Ewald says. “It has been an amazing journey since we sold our very first machine back in 2016. Your faith in our innovations has been instrumental in reaching this achievement.”

Today, DyeMansion is a major provider in the global postprocessing market. Its offerings encompass integrated end-to-end post processing workflows for advanced depowdering, surfacing and coloring solutions — making the technology a vital link in the chain that bridges 3D printed raw parts to their final, high-value products and making the factory of the future with 3D printing a reality.

Headquartered in Planegg, near Munich, Germany, and with a thriving presence in Austin, Texas, DyeMansion is strategically positioned to serve customers worldwide. DyeMansion’s reach spans across 42 countries, with 425 satisfied customers that have experienced the transformative power of the company’s cutting-edge postprocessing solutions. The company is also strengthened by a network of 34 sales partners across the world.

Related Content

Postprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read More8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreWhy AM Leads to Internal Production for Collins Aerospace (Includes Video)

A new Charlotte-area center will provide additive manufacturing expertise and production capacity for Collins business units based across the country, allowing the company to guard proprietary design and process details that are often part of AM.

Read MoreFreeform: Binder Jetting Does Not Change the Basics of Manufacturing

Rather than adapting production methodologies to additive manufacturing, this Pennsylvania contract manufacturer adapts AM to production methodologies. In general, this starts with conversation.

Read MoreRead Next

Alquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read More