Polymer

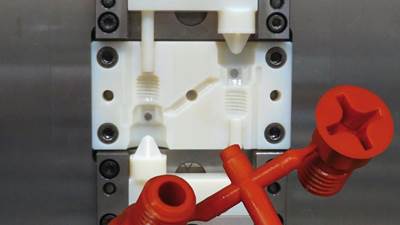

3D Printing Impacts Production Mold Design

3D-printed cavities and cores serve as a testing ground to quickly prove out production mold design options.

Read MoreAgility Through 3D Printing

Additive manufacturing capability has helped this shop stay flexible, in both the prototyping and moldmaking parts of its business.

Read MoreVideo: Microfactories, Large-Scale Machines and 3D Printers in Schools

Lonnie Love of Oak Ridge National Laboratories discusses the various factors that will contribute to the advance of additive manufacturing.

WatchFDM Enables “Smarter” Layup Tools

Building layup tools for composites via FDM eliminates some postprocessing and assembly steps, opening the door to more innovative designs.

Read MoreShaking Off the Support System

Ultrasonics can remove mold support from the surfaces of an additively manufactured part and reduce cleaning time.

Read MoreAdditive Manufacturing with Composites at Carbon Fiber 2015

A cofounder of Arevo Labs will give a presentation on 3D printing with carbon fiber-reinforced polymers.

WatchMachine Shop Turns to Additive for In-House Safety Covers and More

After purchasing a 3D printer to solve a safety issue, turning shop Swiss Automation has found many more applications for the additive manufacturing technology on its shop floor.

Read MoreMaterial Freedom

A maker of engineered plastic components applies a 3D printer that uses the same granulate as molding machines.

Read MoreDevelopmental LSAM Machine Adds Melt Shaping Capability

Development continues on Thermwood’s Large Scale Additive Manufacturing (LSAM) machine with the inclusion of a shaping wheel and plans for subtractive integration.

Read MoreAdditive Manufacturing: Front and Center at SPE’s ACCE

Ford discusses Carbon3D's layerless 3D printing technology.

Read More