FDM Enables “Smarter” Layup Tools

Building layup tools for composites via FDM eliminates some postprocessing and assembly steps, opening the door to more innovative designs.

The layup tools used to form composite materials into their final shape are often milled from steel and other metals. Depending on the tool geometry, this process may require five-axis machining and can generate a lot of scrap. And the more complex the tool, the more expensive it is to produce. Rapid Prototyping Services (RPS), a service bureau based in Satellite Beach, Florida, offers its customers a way to reduce the cost of tooling via its 3D printing services. RPS is able to build layup tools for carbon fiber that are not only more cost-effective, but also “smarter,” using fused deposition modeling (FDM). The thermoplastic extrusion technology simplifies the creation even of complex layup tools.

“With 3D printing, we can do odd shapes and contours just as easily as we can do a square block,” says Ken Brace, RPS owner. The FDM process also offers shorter lead times than machining and makes it faster and easier to iterate designs. Using FDM, RPS has produced layup tools as well as washout mandrels, and coordinated trim and drill tools for composite applications. These tools are printed from high-temperature plastics such as polycarbonate and Ultem, which are able to withstand composite curing temperatures of more than 250°F and pressures ranging to 1,000 psi.

Aside from the cost and time savings the FDM process offers, RPS also reduces postprocessing via a strategy it calls “smart tool integration.” Because of the high pressures and temperatures required during layup and curing, composite tools are often equipped with thermocouple probes and pressure sensors for monitoring. Traditionally, it has been necessary to drill or mill cavities for these devices into the tool after contouring. Once the devices are installed, the cavities must then be sealed with epoxy to hold them inside.

Rather than take these additional steps on its additive-manufactured composite tooling, Rapid Prototyping Services incorporates the cavities for “smart tools” like probes and sensors directly into the layup tool print. Once the cavity is built up, the cycle is stopped and the sensor or other object is installed. The 3D printer can then continue the build over top of the object, sealing it inside, or leave it partially exposed but secure without epoxy or another fastener.

Embedding objects into AM builds is not just for probes in composite tooling, though. RPS has found plenty of other applications for this idea. In addition to sensors and probes, RPS also commonly embeds RFID tags in its composite tools as an identification alternative to tags or labels which can get lost, or engraving which can wear off. Other objects the company has embedded into parts include metal inserts, electronics and wiring.

In another example, the firm used the technique to embed a magnet into a plastic cover for an emergency stop switch to be installed on a painted steel cabinet. Because the door needed to be able to open and close quickly, it was designed with a hinge at the top and a magnet to hold the cover closed. Originally, the customer intended to install the magnet after receiving the parts, but after hearing about Rapid Prototyping’s smart tool integration strategy for its composite tooling, asked if the same technique could be applied to embed the magnet directly into the cover. RPS agreed—but there was just one problem: An FDM printing head is metal, and Brace quickly discovered he would need something to hold the magnet in place while it was being enclosed. “I only made that mistake once,” he says. The solution? A small dab of superglue under the magnet that was allowed to cure before continuing the print.

Related Content

Better, More Compact Radio Frequency Devices Through 3D Printing

3D printing technology company Fortify is applying its photopolymer process and material developed with Rogers Corporation to serve the expanding RF market.

Read MoreVideo: Reinforcing (and Joining) Parts After 3D Printing

Reinforce 3D has developed a method that can be applied to strengthen 3D printed parts by feeding continuous fiber and resin through them. The technique also enables joining parts of various materials and manufacturing methods.

Read MoreAdvancing Additive Manufacturing With a CATCH and Release Approach

Solutions for energy efficiency, sustainability, part repair and more are developing at Siemens’ Charlotte Advanced Technology Collaboration Hub (CATCH) in North Carolina.

Read MoreAircraft Ducts 3D Printed in Composite Instead of Metal: The Cool Parts Show #68

Eaton’s new reinforced PEKK, tailored to aircraft applications, provides a cheaper and faster way to make ducts compared to formed aluminum.

Read MoreRead Next

Postprocessing Composite Tooling: Machining, Coating or Combination Strategy?

A project testing the surface finishing options for composite tooling reveals insight about machining and coating strategies.

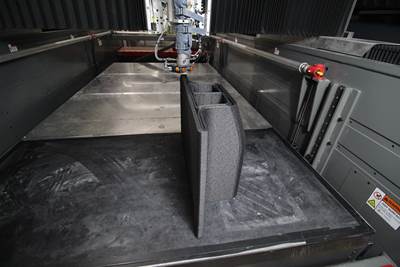

Read MoreOhio Business Sees Big Possibilities in BAAM for Tooling

A new startup built around a large-scale 3D printer aims to offer short lead times for large industrial tools.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More

.jpg;width=70;height=70;mode=crop)