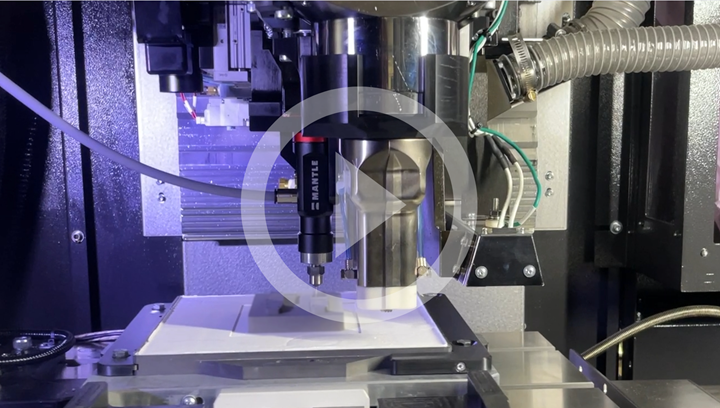

Over 1 Million End Parts Produced With Mold Made on Mantle Metal 3D Printers

Over 1 million end-use plastic parts produced using mold tooling made via the TrueShape system for making precise steel tooling rapidly using 3D printing.

Tessy Plastics Mantle tool insert

Mantle reaches milestone as plastics producers evaluating injection mold tooling made using its system have produced more than 1 million end-use plastic parts using steel tooling obtained from the Mantle 3D metal printing system. The parts range from deodorant packaging to medical devices and dishwasher components.

The company says it has focused on 3D printing the tools used to make these end-use parts, tools which traditionally have been time-consuming and expensive to make, and can be a bottleneck in manufacturers’ product launch schedules. Mantle’s combination of accuracy, surface finish and multiple tool steel materials is said to enable manufacturers to meet stringent tooling needs while reducing lead times and costs by more than 65%, thereby taking months off lengthy and costly hardware development cycles.

“Most of the products we use everyday are manufactured using the types of tools that Mantle prints,” says Ted Sorom, Mantle CEO and co-founder. “Mantle allows companies to evolve with the manufacturing processes, materials and supply chains they know and trust, while realizing a revolutionary improvement in tooling lead time and cost."

Customer success stories include Tessy Plastics, a global contract manufacturer specializing in injection molding and custom automated assembly solutions. It uses Mantle’s 3D printed tooling components in a production tool for a high-volume consumer product. Over 400,000 cycles have run in the tool, which uses multiple 3D printed inserts, and all molded parts have met Tessy’s rigorous quality standards for dimensional accuracy and surface finish. [Update: Since this news was posted, Tessy has continued producing with the tooling, which has now performed well past 1.65 million cycles.]

Another success is a multinational medical device manufacturer that has reduced the lead time for a prototype tool from 12 weeks to 4 weeks, and reduced the cost by over 65% by using Mantle’s 3D printed tooling components. The printed mold components met the manufacturer’s strict accuracy and surface finish requirements, and all molded parts met the requirements for dimensional accuracy and mechanical properties.

Related Content

-

8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples.

-

The Connector Conundrum: 3D Printed Mold Tooling’s Role in Innovation

ReelView Fishing faced an electronics obstacle in the development of its new technology for underwater video. Additive manufacturing for moldmaking allowed for the speed necessary to iterate to a solution. How inventors and invention will benefit from new ways of obtaining production-ready tooling.

-

Mantle: 3D Printed Molds Address Plastics Industry Lead Time and Skills Shortage

Company now shipping production systems. Steel mold tooling from its TrueShape process can be printed, shaped and sintered in days, and with fewer steps, compared to weeks of lead time for molds made conventionally.