Mold Tooling

Combining Metal and Polymer for Better 3D Printed Tools

Applications prone to wear call for more durable tooling than 3D printed polymer alone, but full metal is not always necessary.

Read MoreSK Industriemodell’s Technology Designed to Accelerate, Improve Development Cycles of Prototypes, Components and Products

Formnext 2024: Technology enables the development of sophisticated components.

Read MoreVideo: Hybrid Manufacturing Without Melting: Hermle’s Metal Powder Application (MPA) Process

The Metal Powder Application (MPA) process uses cold spray to apply metal to an existing workpiece. Because the material deforms rather than melts, MPA opens new possibilities for functional grading and other multimaterial applications.

WatchAirtech and Ascent Aerospace Collaborate to Promote Additive Manufacturing Tooling in Aerospace, Defense

By combining Airtech’s high-performance materials and Ascent’s production capabilities, the companies aim to support the adoption of polymer composite additive tooling to some of the most demanding applications and customers in the world.

Read MoreThe Connector Conundrum: 3D Printed Mold Tooling’s Role in Innovation

ReelView Fishing faced an electronics obstacle in the development of its new technology for underwater video. Additive manufacturing for moldmaking allowed for the speed necessary to iterate to a solution. How inventors and invention will benefit from new ways of obtaining production-ready tooling.

Read MoreVideo: Mold Base for Product Development With 3D Printed Molds

Alba Enterprises created a mold base to match the needs and pacing of product iteration using mold tooling made via additive manufacturing

WatchXact Metal Works With Uddeholm as It Expands Into Tooling, Molding

Uddeholm’s Corrax for additive manufacturing is a corrosion-resistant, cobalt-free tool and mold steel capable of an A1 surface finish post-polishing.

Read MoreMake Every Shot Count: Mold Simulation Maximizes Functional Parts From Printed Tooling

If a printed tool only has a finite number of shots in it, why waste any of them on process development?

Read MoreAPSX and Nexa3D Integrate Technologies to Advance Freeform Injection Molding

With the combined APSX-PIM and Nexa3D technologies, users can seamlessly transition from 3D printing prototypes to injection-molded production parts, all within a single, integrated ecosystem.

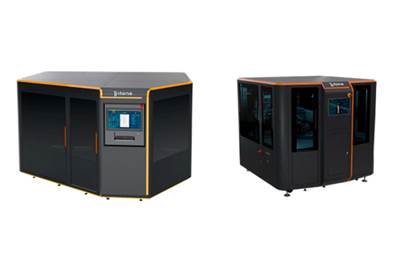

Read MoreTritone Technologies Forges US Strategic Alliance With Adia

Tritone’s technology enables quick and easy switching between a wide variety of metals and ceramics, making it possible to simultaneously manufacture parts of different sizes, shapes and applications.

Read More