Video: Mold Base for Product Development With 3D Printed Molds

Alba Enterprises created a mold base to match the needs and pacing of product iteration using mold tooling made via additive manufacturing

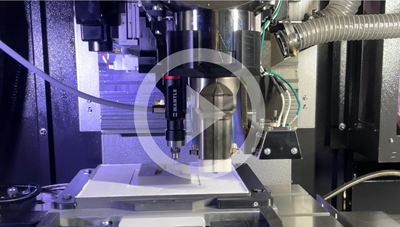

Alba Enterprises LLC developed the mold base seen below and in the video above specifically with 3D printed mold tooling in mind. That is, steel mold tooling made additively, perhaps through laser powder bed fusion or through the Mantle TrueShape metal paste process. The chief benefit of making this tooling additively is in product development, Alba says. Tools that are capable of production molding can be made in lead times short enough for rapid iteration of the mold design and molding process. This video shows a mold base Alba created specifically for this mode of product development.

Video Transcript

How can the injection molding process adapt to help better realize the promise of 3D printed mold tooling? Look at this. This is a mold base set designed by Alba Enterprises. I'm here at their facility. This mold base is tailored to a mold sized to be two inches square. Why that size? Because Alba has discovered that at that size, the cooling of this mold base alone is sufficient to maintain the required temperature of the mold. That means no cooling lines are needed for the mold itself. That brings real freedom to the mold design. It allows 3D printed mold making, already a fast way to obtain a mold, to proceed even faster. That means: iterate quickly. Check the design. Check the process. Change the design. Change the process. Keep doing that within tight, fast, iterative loops, all using tooling and a process that can become, will become, the production process when the final solution is realized. This is the Babyplast miniature, precise injection molding machine that Alba Enterprises provides. Ten-ton mold clamping force. Alba has used this system to run 3D printed mold tooling made of laser powder bed fusion, made using the Mantle True Shape process, even polymer 3D printed molds in some cases. Another feature of this mold set this array of injector pin holes, always ensuring that there is a pin at the right location for these small injection molded parts made with 3D printed tooling.

Related Content

4 Weeks from Design to Molded Part for Medical with Metal 3D Printed Tooling

Mold builder Westminster Tool applied the Trueshape process from Mantle to produce tooling to take a medical device from prototype mold to full-scale production in a matter of weeks.

Read MoreHow Avid Product Development Creates Efficiencies in High-Mix, Low-Volume Additive Manufacturing

Contract manufacturer Avid Product Development (a Lubrizol company) has developed strategies to streamline part production through 3D printing so its engineering team can focus on development, design, assembly and other services.

Read MoreIndyCar's 3D Printed Top Frame Increases Driver Safety

The IndyCar titanium top frame is a safety device standard to all the series' cars. The 3D printed titanium component holds the aeroscreen and protects drivers on the track.

Read MoreAdditive Manufacturing's Evolving Role at Fathom Now Emphasizing Bridge Production

Bridge production is currently the biggest opportunity for additive manufacturing, says Fathom Manufacturing co-founder Rich Stump. How this service provider leverages AM while finding balance with other production capabilities.

Read MoreRead Next

8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples.

Read More3D Printing Molds With Metal Paste: The Mantle Process Explained (Video)

Metal paste is the starting point for a process using 3D printing, CNC shaping and sintering to deliver precise H13 or P20 steel tooling for plastics injection molding. Peter Zelinski talks through the steps of the process in this video filmed with Mantle equipment.

Read MoreThe Connector Conundrum: 3D Printed Mold Tooling’s Role in Innovation

ReelView Fishing faced an electronics obstacle in the development of its new technology for underwater video. Additive manufacturing for moldmaking allowed for the speed necessary to iterate to a solution. How inventors and invention will benefit from new ways of obtaining production-ready tooling.

Read More