Lightweighting with Lattices

Building components as a network of unit cells may improve material utilization and performance.

Share

Read Next

In two previous articles, we’ve explored two “speed plays” enabled by additive manufacturing (AM): direct part replacement and functional prototyping. In both cases, we also saw the related challenges of additively manufacturing parts that were not designed to be fabricated layer by layer. Namely, these challenges involved extensive postprocessing to remove support structures and finish the parts so that they would be comparable to traditionally machined parts.

We used the example of a piston crown to show how adapting a design for AM can help avoid some of the challenges. But if you had the freedom to design and develop a completely new geometry for additive manufacturing, could you improve part quality and performance, and reduce costs? I have mentioned techniques like topology optimization and conformal cooling before, but here I’d like to discuss lattice structures, which AM can produce much more easily than conventional manufacturing.

A lattice is made of repeated unit cells. There are countless options for the size and shape of such a cell, and for how it is repeated, and there are a lot of examples of lattice structures being used to provide internal support, reduce the amount of material or improve the strength-to-weight ratio of an AM component.

Lattices can be uniform, meaning the exact same cell is repeated in all directions, or variable, meaning the size or spacing of the cells is different in different directions. Variable lattice structures are gaining traction in medical applications such as implants, as the variability of the cells enables such implants to better mimic our own bones. Bones are not solid, fully dense structures, so lattices can provide comparable strength-to-weight ratios and better osteointegration, resulting in quicker recovery and better performance.

An added benefit of lattice structures is they can be additively manufactured faster, using less material and therefore requiring less build time than fully dense, solid components. This improved material utilization in some cases also allows use of better, more expensive materials.

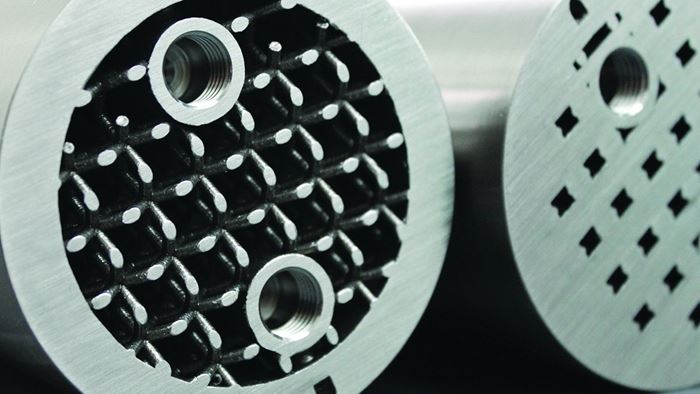

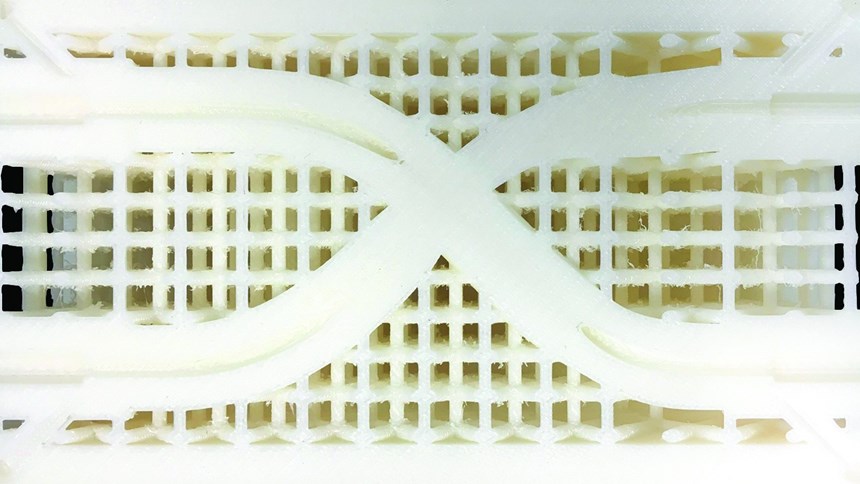

Case in point is the oil and gas component for downhole applications shown in Figure 1. This component pumps fluid up and down an oil well by means of “snaky” internal channels (see Figure 2). Traditionally, it is made by carefully machining internal channels into a solid block of metal. The internal shapes that can be machined and the height of the component that can be achieved are limited. AM allows for virtually any internal shape, and, in this case, we used lattice structures to support the component’s internal geometry while using less material and thereby reducing its overall weight. And because we were able to use less material, we could afford to use a higher-grade alloy that will not only extend the life of the component, but also offer improved corrosion resistance.

The additively manufactured component is 40 percent lighter than the machined component would be. Could we have achieved this reduced weight through traditional machining? Sure, we could machine out holes and features to lightweight the component, but we could not machine the lattice structure throughout the entire part. And we would have to start with a solid block of material and machine much of it away, which would not have allowed us to substitute a more expensive material. In the end, additive manufacturing enabled us to build a component that performs better, lasts longer, is lighter weight and cannot easily be manufactured any other way.

I will note that, even though we additively manufactured this component, machining was still needed to thread holes so it could be connected to a test rig. A special thanks to the team at Imperial Machine and Tool Co. for finishing this part for us. This shop is well-experienced in working with AM materials and components, having purchased a laser-based, powder-bed fusion system several years ago. In fact, its business has grown so much that the shop recently acquired a second AM system. (Read about Imperial Machine and Tool’s journey.)

I realize that not everyone can afford that level of investment, but this is another example of how AM also is changing the nature of work for machining professionals. You may not be asked to drill and machine the internal channels of a component such as this one, but instead to just finish off one that was built more economically through AM, thanks, in this case, to lightweighting with lattice structures.

This article originally appeared in Additive Insights, a monthly column in Modern Machine Shop magazine.

Related Content

Velo3D Founder on the 3 Biggest Challenges of 3D Printing Metal Parts

Velo3D CEO and founder Benny Buller offers this perspective on cost, qualification and ease of development as they apply to the progress of AM adoption in the future.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

Read MoreReusable LOX/Kerosene Engine Completes First Successful Full-System Test Flight

Galactic Energy Space Technology announced the first successful full-system test flight of its Welkin 50-ton reusable LOX/kerosene engine. To date, this is the highest thrust LOX/kerosene engine in the Chinese commercial aerospace playing field which has officially entered the engineering and manufacturing phase.

Read MoreRead Next

Profilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More