Dyndrite Joins NMIS to Advance 3D Metal Manufacturing Research

Dyndrite has joined NMIS to help develop build recipes and shareable knowledge in materials process development across all major laser powder bed fusion OEM file formats.

Share

Read Next

Photo Credit: Dyndrite

Dyndrite has joined the National Manufacturing Institute Scotland (NMIS) to further research on 3D metal printer manufacturing. NMIS membership provides access to world-leading expertise, technical capability and opportunities to innovate together on the global stage.

NMIS plans to use Dyndrite in developing build recipes and shareable knowledge in materials process development across all major laser powder bed fusion (LPBF) OEM file formats. Dyndrite is the provider of a GPU-accelerated computation engine used to create next-generation digital manufacturing hardware and software.

The company will collaborate with researchers from the NMIS Digital Factory which is focused on developing LPBF process materials knowledge across multiple industries. The group will work on a variety of R&D projects, from assessing fatigue strength and corrosion resistance for biomedical applications, to finding the best materials properties for parts used within the energy sector.

NMIS members include Infor, Baker Hughes, Fanuc, ATS Global, Sandvik, Skyreal, Hybrid Manufacturing Technologies, Beckhoff, Nikken and Renishaw. Dyndrite joins this fast-growing roster of innovators looking to collaborate on complex additive manufacturing (AM) problems, particularly around expanding available materials and production automation.

“We are delighted to join forces with NMIS and members to develop AM metals materials and explore production automation of LPBF using repeatable build recipes,” says Stephen Anderson, Dyndrite’s head of strategic relationships. “By removing variation in the print process, we showcase how additive manufacturing scales to allow users to make more parts with greater consistency at a lower price. This is the key to unlocking new markets in 3D metal printing. This effort will drive metal AM into a mainstream production process and enable simpler traceability from powder to part.”

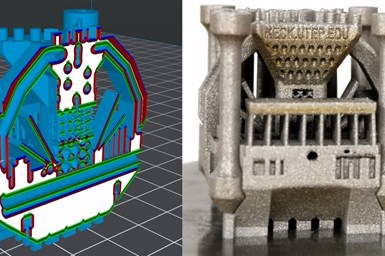

Dyndrite’s first end-user AM application is the Dyndrite Materials and Process Development for LPBF. This GPU-based 3D application (designed for engineers and scientists) simplifies and brings automation to the development of metal alloys and parts for laser-based 3D metal printing. It takes maximum advantage of Dyndrite’s Accelerated Computation Engine (ACE), including the ability to query 3D geometry in order to detect and optimize for difficult to print features such as domes, cantilevers and thin walls.

Dyndrite’s LPBF application increases print throughput, speeds development and lowers part costs. Users can also create and share build recipes (Python) that provide all the information required to recreate a build and drive the manufacturing process. Dyndrite’s LPBF application outputs to leading 3D metal printers, including Aconity3D, EOS, Renishaw, SLM and others.

“We’re excited to welcome Dyndrite as our newest NMIS member, where they will be working with our additive team,” says Stephen Fitzpatrick, NMIS Digital Factory director. “Dyndrite is a leading provider of 3D software for engineering and manufacturing applications. Our deployment will immediately help develop and grow our AM materials capabilities. Over the next year, we aim to collaborate on research projects that showcase novel additive use cases within process qualification and calibration and automated production lines. We look forward to getting started.”

- Learn about another Dyndrite collaboration, this time with MIMO Technik and Astro on machine, material qualification for 3D metal printing. The companies are collaborating on the development of the Mastro process in order to streamline and automate a closed-loop source for additive production and qualification.

- Read about Dyndrite joining ASTM to provide AM reference data. The collaborative effort aims to create shareable reference datasets that drive consistency across the industry, accelerating qualification and adoption of metal additive manufacturing.

Related Content

3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

Read More3MF File Format for Additive Manufacturing: More Than Geometry

The file format offers a less data-intensive way of recording part geometry, as well as details about build preparation, material, process and more.

Read MoreOvercoming the Bottleneck to Customized Manufacturing: Quoting

Spokbee’s software-as-a-service platform is shaving months off of the quoting and pricing process for 3D printed and other types of configurable products.

Read MoreCopper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

Read MoreRead Next

Crushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More