AddUp Participates in $1.5M USAF Research on IN-718 Additive Manufacturing

AddUp is partnering with Zeda to provide critical project support to provide the USAF with a set of manufacturing guidelines to maximize the capabilities of LPBF to meet fleet readiness and sustainment goals.

AddUp Inc. has joined a $1.5 million research contract for the “Development of Manufacturing, Heat Treatment and Surface Finishing Guidelines to Yield Ready-to-Use IN-718 Additive Manufacturing Components” for the United States Air Force (USAF). The program is being run through the USAF and the Small Business Innovation Research (SBIR) program led by REM Surface Engineering (REM).

The USAF is constantly seeking innovative solutions to enhance the readiness and performance of its armament systems. In pursuit of this goal, this project was proposed and awarded. It is funded through a Direct to Phase II Small Business Innovation Research (SBIR) contract, and aims to harness the potential of laser powder bed fusion (LPBF) and surface finishing technologies to produce IN-718 components for legacy armament systems.

This endeavor is researching the impact of various heat treatment and printing parameter combinations in association with REM’s surface finishing technology on a component’s mechanical properties, such as tensile strength and fatigue life. AddUp and Zeda (formerly PrinterPrezz and Vertex Manufacturing) are providing critical support to this project which aims to provide the USAF with a set of manufacturing guidelines to maximize the capabilities of LPBF to meet fleet readiness and sustainment goals.

Fatigue strength plays a critical role in ensuring the reliability and longevity of components used in demanding applications within the USAF. IN-718, a nickel-based superalloy material known for its exceptional mechanical properties and resistance to high temperatures and corrosive environments, has gained significant importance in aerospace and defense industries.

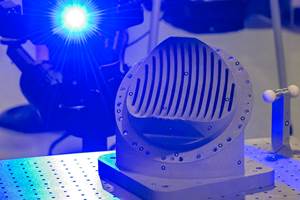

The combination of fine powder and a roller recoater in AddUp’s FormUp 350 machine provides a synergistic effect on surface finish improvement, leading to enhanced fatigue properties in IN-718 material. By achieving a more uniform powder layer, reducing surface irregularities and minimizing defects, the fatigue resistance of the printed components is significantly improved. This is particularly crucial in aerospace and defense applications, where fatigue performance is critical for long-term structural integrity and operational reliability.

To ensure the integrity and reliability of the IN-718 AM components, fatigue testing is a crucial step. AddUp, in collaboration with Zeda, will manufacture IN-718 fatigue specimens using LPBF technology with AddUp’s FormUp 350. These specimens will be utilized in REM’s testing matrix to establish expected material properties of LPBF components with several levels of surface finish and with different manufacturing and heat treatment parameters. Through this collaborative effort, the project seeks to validate the fatigue strength of IN-718 AM components manufactured via AddUp’s FormUp 350 LPBF technology.

The development of manufacturing, heat treatment, and surface finishing guidelines to yield ready-to-use IN-718 Additive Manufacturing Components project represents a significant step forward in advancing the USAF's capabilities and readiness. By leveraging the capabilities of LPBF technology and conducting rigorous fatigue testing, this project strives to enhance the performance, reliability and cost-effectiveness of aerospace and defense components production, reducing downtime and ensuring mission-critical operations can proceed smoothly.

- Read more about Zeda collaborating with AddUp for aerospace, medical additive manufacturing. The first of eight AddUp FormUp 350 powder bed fusion machines deployed has been installed at Zeda to support its growth in the aerospace and medical sectors.

- Read about the new Zeda additive manufacturing factory in Ohio that will serve medical, military and aerospace production, and includes laser powder bed fusion (LPBF) machines from AddUp and Velo3D.

Related Content

At General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More3D Printed Titanium Replaces Aluminum for Unmanned Aircraft Wing Splice: The Cool Parts Show #72

Rapid Plasma Deposition produces the near-net-shape preform for a newly designed wing splice for remotely piloted aircraft from General Atomics. The Cool Parts Show visits Norsk Titanium, where this part is made.

Read MoreAdditive Manufacturing in Space: Failing Upward

Not all 3D printed parts destined for space need to adhere to the standards of human space flight. Yet all parts made for space programs require some type of qualification and certification. NASA and The Barnes Global Advisors explore Q&C for these parts.

Read MoreHow Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

Read MoreRead Next

Profilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More